Review: Fatigue Properties of Ti-6Al-4V Alloys Fabricated by Metal Injection Moulding

Keywords:

Metal injection molding, Fatigue, Sintering, Grain refinement, Shot peeningAbstract

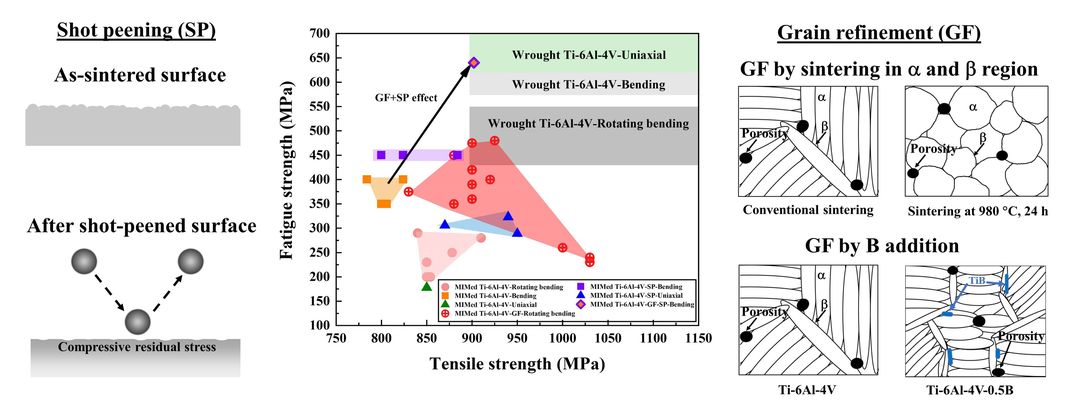

Metal injection moulded Ti-6Al-4V alloy exhibits sufficient tensile properties, however, the fatigue properties are not comparable to the wrought alloy. This is due to the residual porosity and coarse microstructure, which stems from the sintering process. This review presents a comprehensive assessment of the physical properties, tensile properties, fatigue properties, related processing parameters and potential methods to improve the fatigue properties of the Ti-6Al-4V alloy fabricated by metal injection moulding (MIM). The potential methods to improve the fatigue properties of the MIMed Ti-6Al-4V are the grain refinement methods by the addition of alloying elements or by sintering in the alpha and beta phase temperature region, the surface treatment method by shot peening process, and the higher binder content method. All these methods can improve the fatigue properties of the MIMed alloy to different extents. The most effective method, which can provide fatigue properties comparable to the wrought alloy, is when both grain refinement and shot peening are simultaneously applied. This paper should be useful for people who are interested in the fatigue properties of the Ti-6Al-4V fabricated by MIM.