Microstructural and Interfacial Designs of Dual-Phase Oxygen Permeable Membranes for Oxygen Separation Application

Keywords:

Dual-phase membrane, Composite materials, Spark plasma sintering, Yttria-stabilized zirconiaAbstract

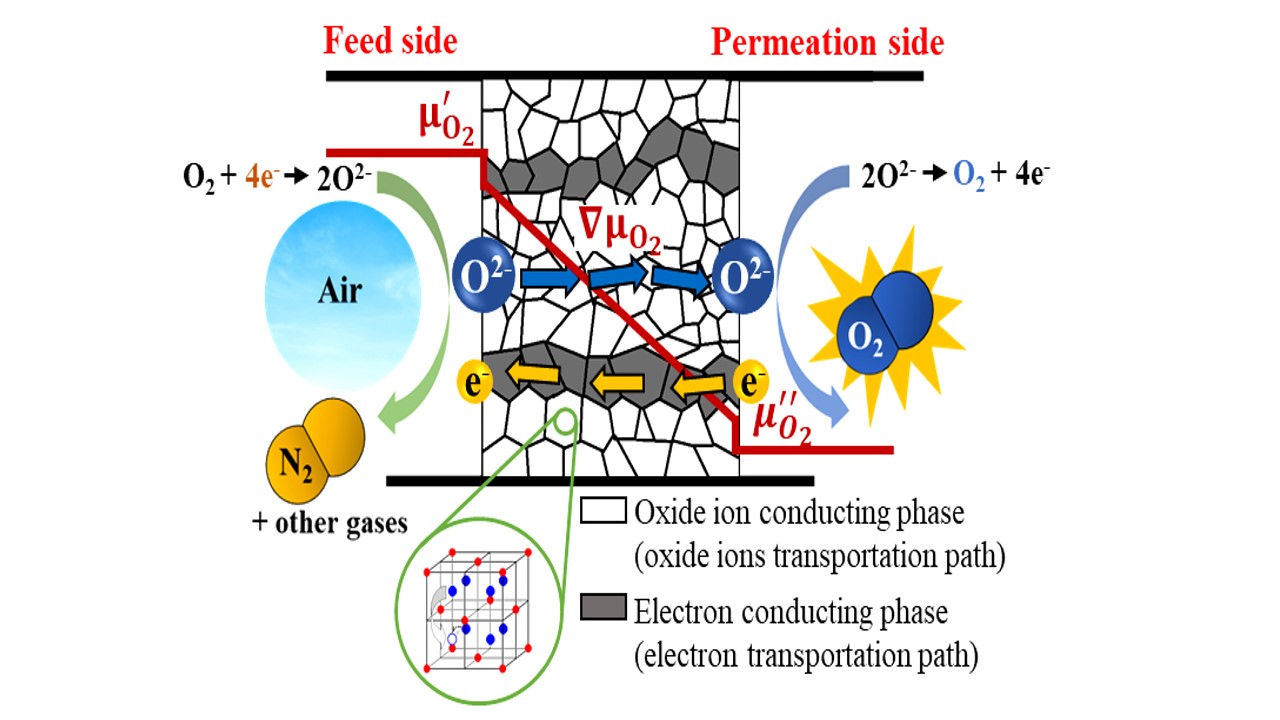

A new and simple fabrication method by using a vacuum infiltration and spark plasma sintering (SPS) process for a dual-phase oxygen separation membrane consisting of electronic and ion-conducting phases has been presented. This method is able to form a co-continuous microstructure of the dual-phase and can realize the theoretical structure of a dual-phase membrane that has high efficient conducting paths of both carriers. The slurry of oxide ion-conducting materials (8 mol% yttria-stabilized zirconia (8YSZ)) was filled in a porous body of electron-conducting materials (carbon felt and nickel foam) by a vacuum infiltration process, then sintered by SPS process under the applied pressure of 80 MPa. The YSZ-based dual-phase membrane with a gas-tight and co-continuous structure, high chemical compatibility, and good phase stability was successfully fabricated. Finally, the ability to separate oxygen gas from air of a selected sample, the YSZ-nickel foam dual-phase membrane sintered at 1200 °C was investigated. The highest oxygen permeation flux of 0.21 ml/min·cm² was achieved at 800 °C, suggesting that this new processing route could be used for fabricating the oxygen separation membrane.