Chemical Recycling of Post-consumer Polylactide Products by Microwave-Assisted Aminolysis with Ethylenediamine

DOI:

https://doi.org/10.48048/siam.2025.68007Keywords:

Chemical recycling, Aminolysis, PLA, Microwave-assisted, Circular economyAbstract

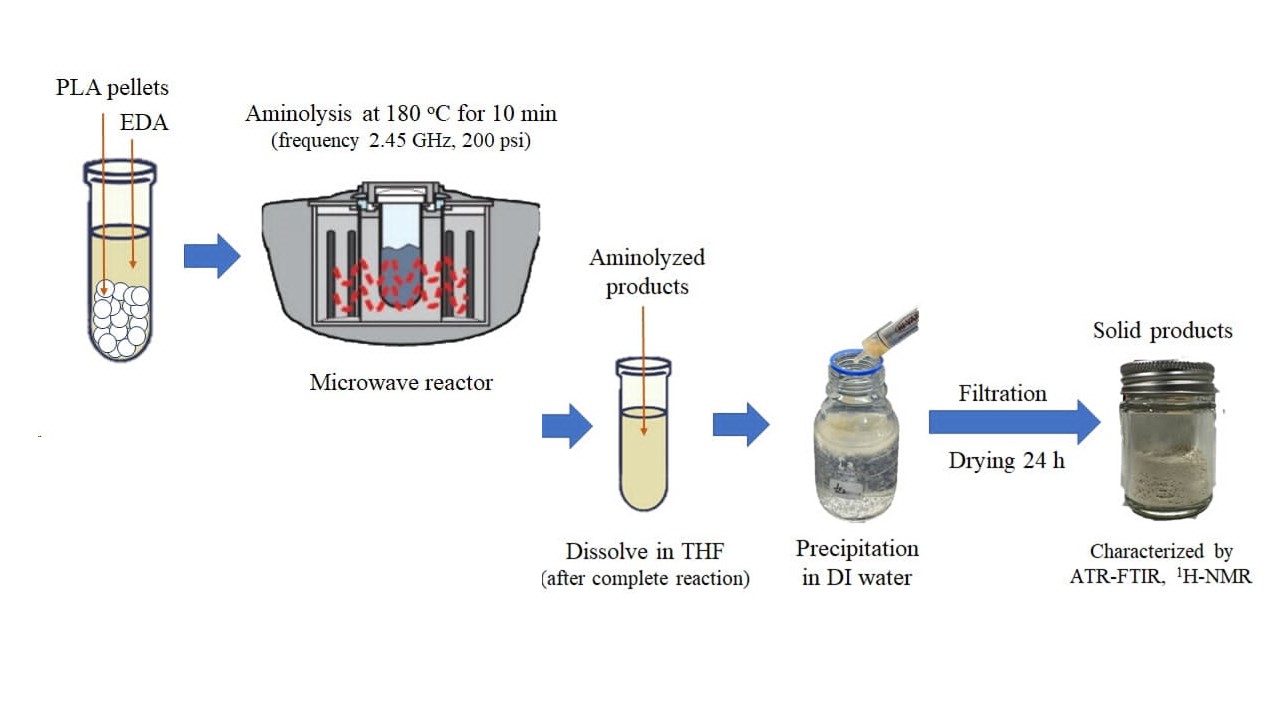

The demand for bioplastics has recently increased as a promising alternative to conventional plastics due to their degradability, renewability, and excellent properties compared to their fossil-based counterparts. Although these materials are degradable, recycling their post-consumer products is considered effective and sustainable, especially by converting them into value-added feedstocks or starting materials for other processes. In this work, a chemical recycling process for polylactide (PLA) by aminolysis depolymerization is developed, employing a diamine as a nucleophile to cleave the ester bonds of PLA. The process utilizes microwave irradiation and ethylenediamine (EDA) as a reactant. The effects of the PLA/EDA feed ratio on the chemical structures and compositions of the aminolyzed PLA oligomers are investigated by ATR-FTIR and 1H-NMR spectroscopy. The chemical structures and average length of the lactate sequences are determined. The product mixture consists of amino-capped lactate sequences of different lengths, i.e., mono-lactate, di-lactate, and poly-lactate. These are classified into two structures: Structure A is generated when a single -NH2 of EDA reacts and attaches to lactate sequences, while Structure B is formed when both amine groups react. At a low PLA/EDA feed content of 5:1, the aminolyzed products consist of 91% Structure A content with the shortest average lactate length of 0.9 units, as the high EDA feed content effectively enables its -NH2 groups to compete with each other to convert the ester bonds of PLA. When the feed ratio was increased to 30:1, Structure B became a major product at 85%, with an average lactate length of 11.1, due to the deficit of -NH2 groups in the system. The variation in these reaction parameters enables the synthesis of products with tunable structures for use in specific applications. The developed process is promising for converting PLA waste, with a short reaction time, into starting materials for other value-added products, especially lactide-based polyurethanes.