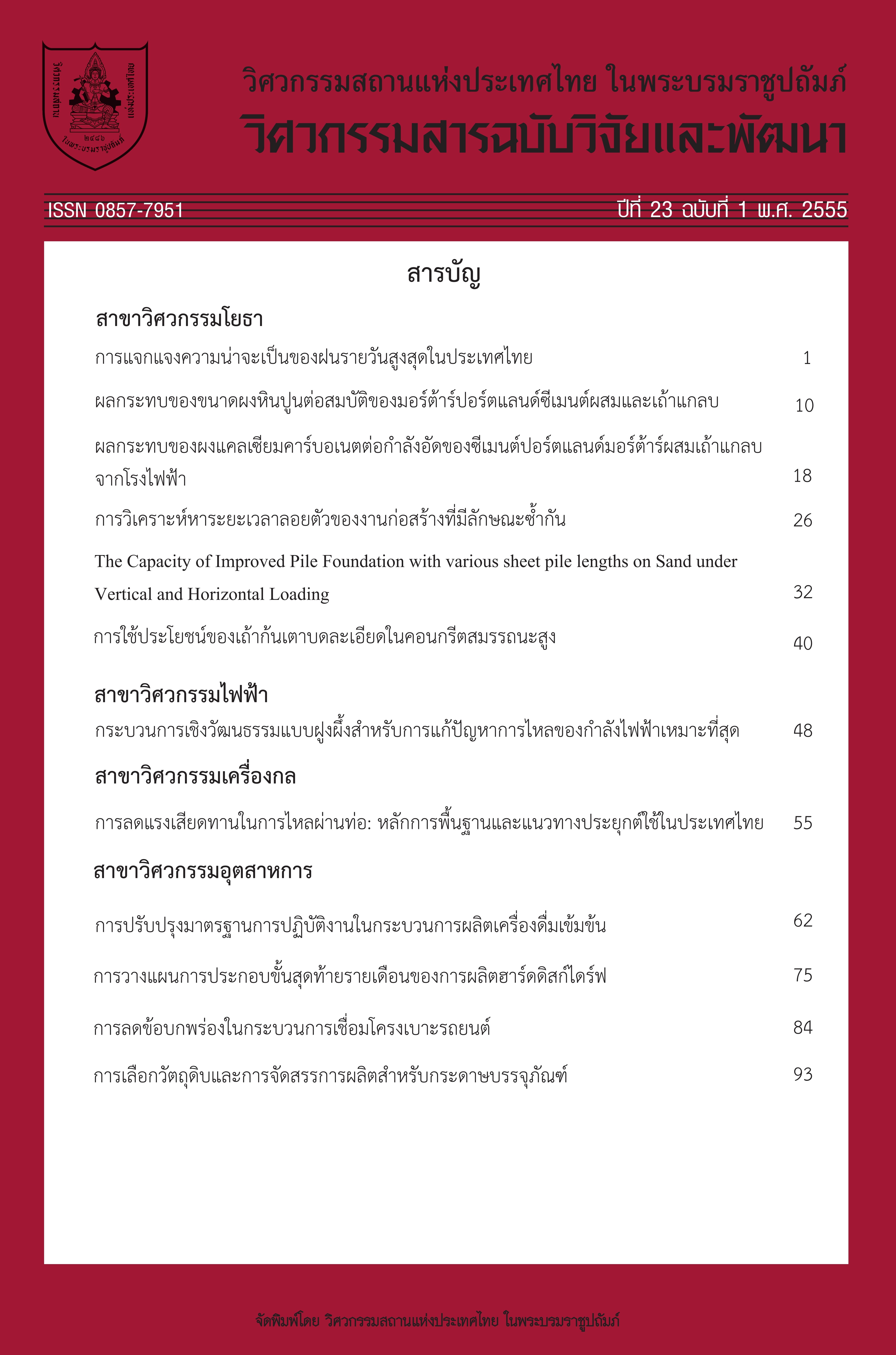

ผลกระทบของผงแคลเซียมคาร์บอเนตต่อกำลังอัดของซีเมนต์ปอร์ตแลนด์มอร์ต้าร์ผสมเถ้าแกลบจากโรงไฟฟ้า

Main Article Content

Abstract

Abstract

This paper presented the development of the compressive strengths of mortars consisting of Portland cement Type 1 of which was replaced by rice husk ash (RHA) from electric power plant and calcium carbonate (CaCO3) that having averaged particle sizes (D[4,3]) of 29.30, 3.80 and 4.50 mm, respectively with the replacement levels at 0%, 20% and 40% by weight of powder materials. The water-to-powder materials ratios equal to the water requirement conforming to flow value at 110% ± 5%. From the test results, it was found that CaCO3 can reduce the water requirements of mortars. At 28 days, mortar containing 5% RHA and 15% CaCO3 had the highest compressive strength. Whereas, at the age of 150 days, the 10% RHA and 10% CaCO3 mortar is the highest development in strength and also similar to the control mortar.

Article Details

The published articles are copyright of the Engineering Journal of Research and Development, The Engineering Institute of Thailand Under H.M. The King's Patronage (EIT).