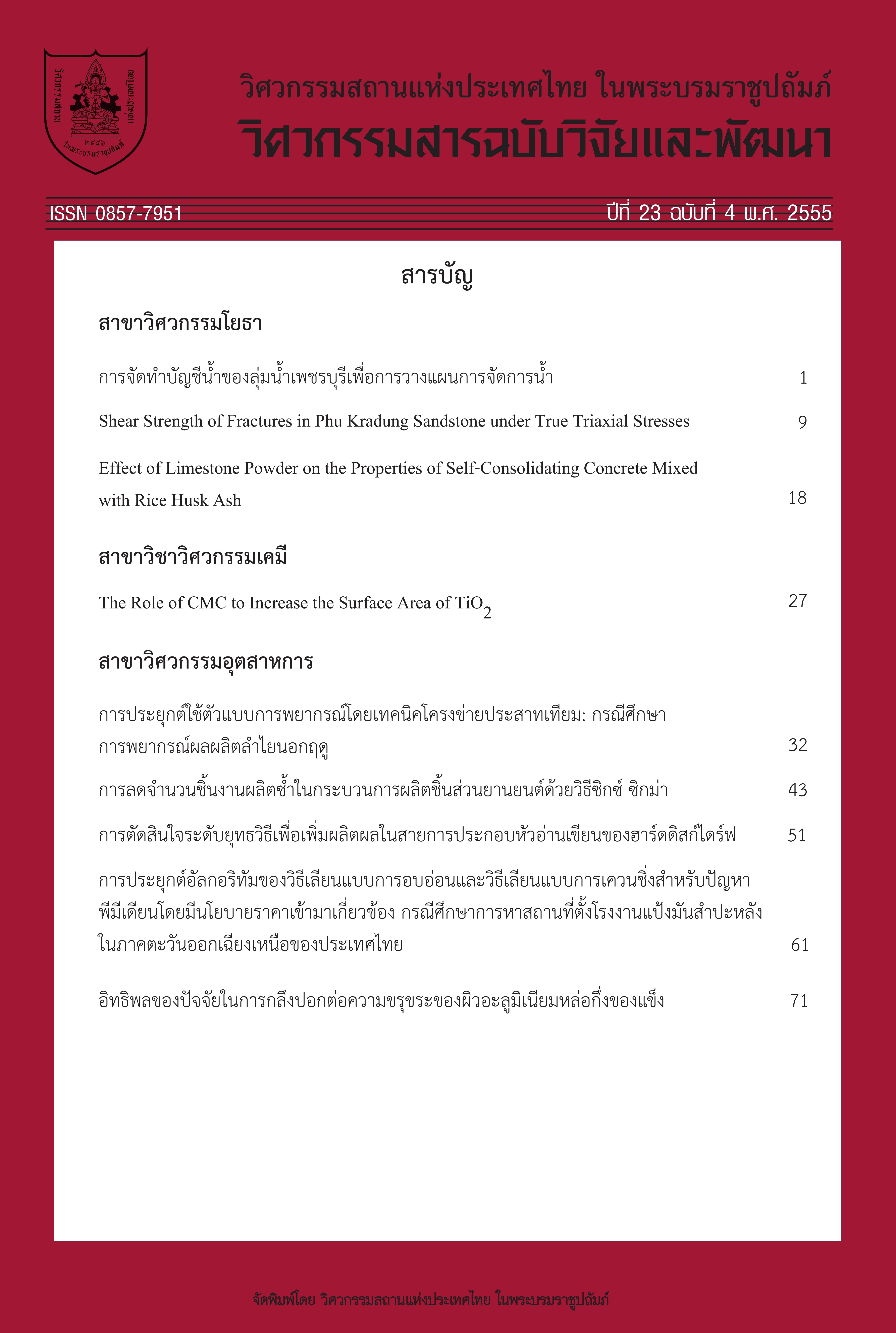

The Role of CMC to Increase the Surface Area of TiO2

Main Article Content

Abstract

Abstract

The aim of this work was to find the optimum condition for synthesis of titania particles by sol-gel technique using precursor solution of titanium (IV) isopropoxide in toluene and 2 mol L-1 aqueous solution of potassium hydroxide. The concentration of precursor solution was 0.3, 0.5 and 0.7 mol L-1. The obtained sol was dried at 80°C for 2 h and calcined in air at 400, 500 and 700°C for 2 h. The effect of carboxy methyl cellulose (CMC) on physical properties of prepared titania was studied by addition of 1-2 mL of 1% w/v of CMC aqueous solution in 0.7 mol L-1 of precursor solution. The obtained titania particles was characterized by XRD and SEM. Brunauer-Emmett-Teller surface areas have also been determined. The results showed that all titania particles were anatase phase, the particles size was in range of 5.49-26.30 nm and the average surface area of titania particles were in the range of 27.75-196.30 m2g-1. It was also found that titania with 2mL of CMC solution loading gave the highest average surface area.

Article Details

The published articles are copyright of the Engineering Journal of Research and Development, The Engineering Institute of Thailand Under H.M. The King's Patronage (EIT).