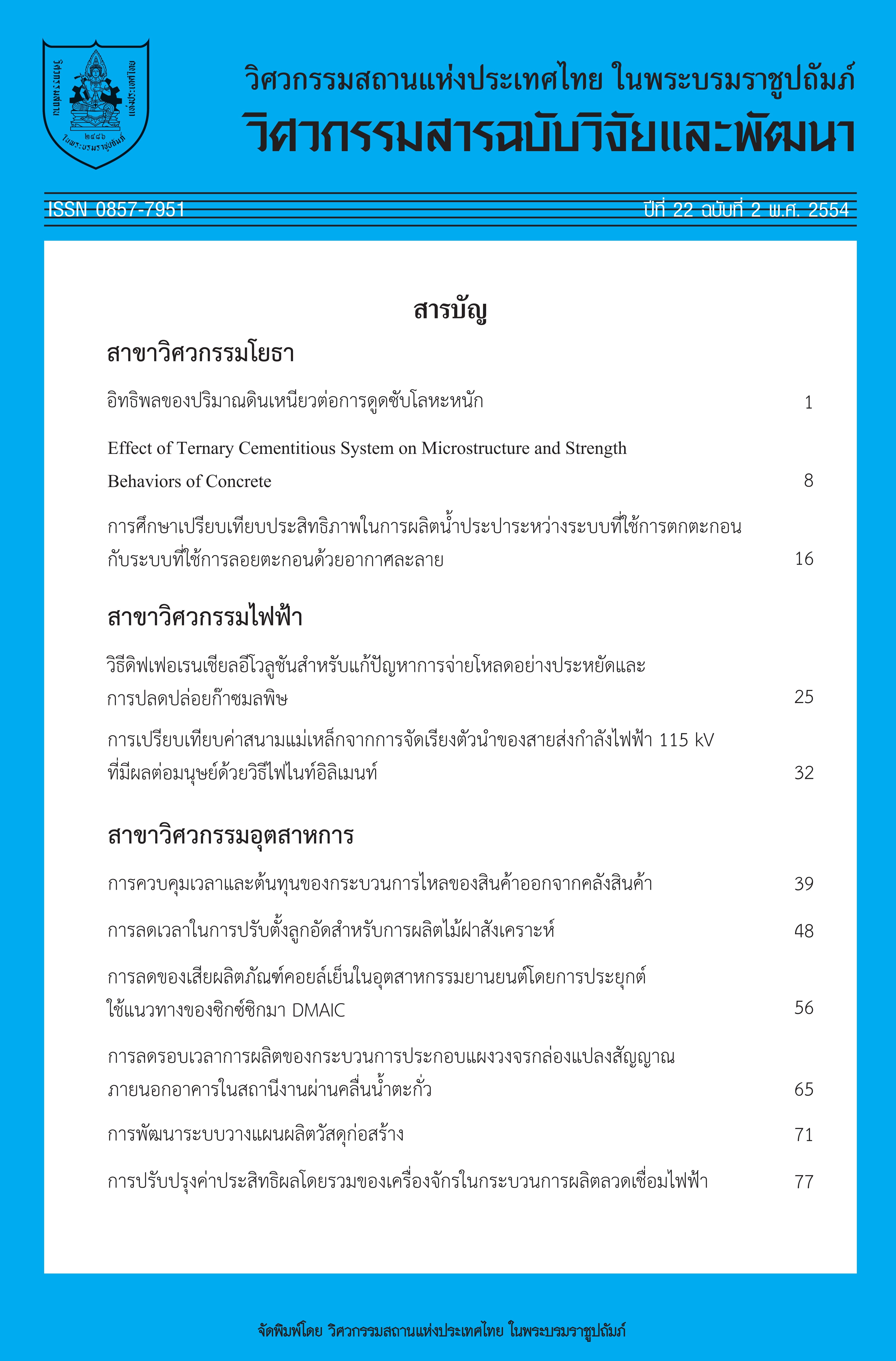

การปรับปรุงค่าประสิทธิผลโดยรวมของเครื่องจักรในกระบวนการผลิตลวดเชื่อมไฟฟ้า

Main Article Content

Abstract

The objective of this thesis is to improve the overall equipment effectiveness for Welding electrode Manufacturing Process with the target more than 70%. The study focused on drawing & cutting, cutting, coating, dying & Packaging . The data collection was conducted 3 months . After that the raw data was calculated for the overall equipment effectiveness of each machine group; 84.53% for drawing and cutting machine group, 89.18% for cutting machine group, 45.98% for coating machine group, 55.65% for drying & baking oven group, the average for all machine group was 68.84%. Work study, Pareto and fish-bone diagram were used to analyze the causes of problem. After implementation. The result was as follows; 86.60% for drawing & cutting machine group, 93.83% for cutting machine group, 79.50% for coating machine group, 72.86% for drying & baking machine group. The average for all departments was 83.16% which was increased by 17.21%

Article Details

The published articles are copyright of the Engineering Journal of Research and Development, The Engineering Institute of Thailand Under H.M. The King's Patronage (EIT).