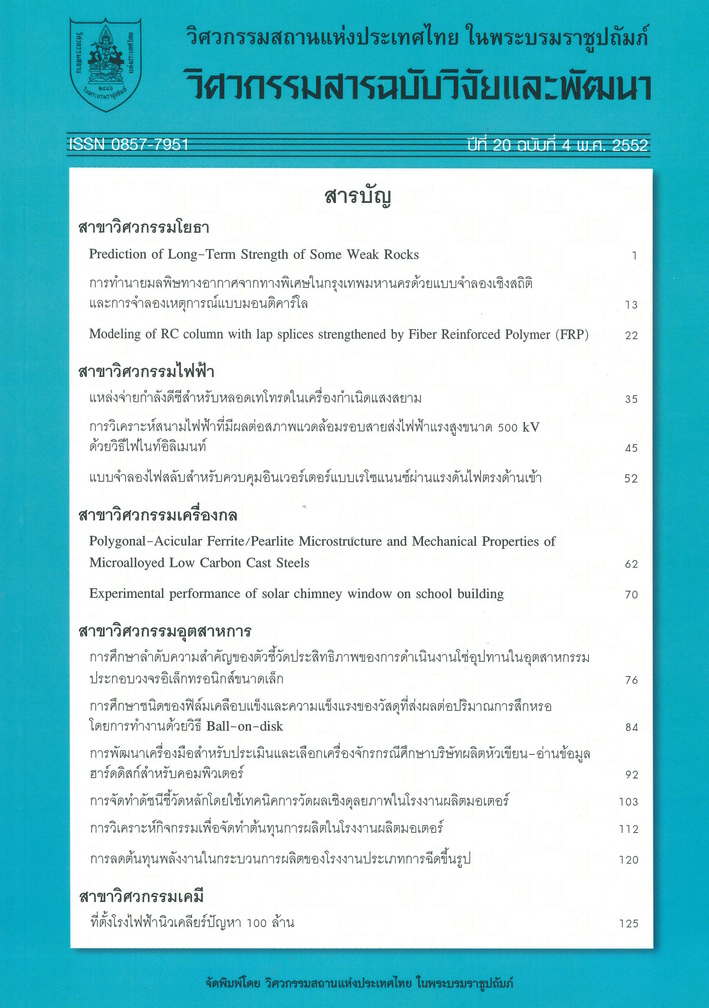

การศึกษาชนิดของฟิล์มเคลือบแข็งและความแข็งแรงของวัสดุ ที่ส่งผลต่อปริมาณการสึกหรอ โดยการทำงานด้วยวิธี Ball-on-disk

Main Article Content

Abstract

This research considered various types of coating on tool surface which was regularly practiced in modern stamping industries due to the ability to increase wear resistance. The model studied of friction “Ball-on-disk” technique was employed through out this work. The disks were made from high tensile steel grade SAPH 440, SPFH 590 and SPFC 780 of 2 mm thicknesses. The steel balls of 6 mm in diameter were made from tool steel grade JIS SKD11 hardened before coated film to 60 ± 2 HRC. Ball surface conditions for this research were non-coated, TiAlN, TiN and TiCN-CVD coated film. The experiments were conducted under dried condition and controlled temperature at 25 °C. The normal load of 10 N and sliding speed of 10 cm/s were used for all experiments. The results showed that high strength of steel causes high friction coefficient. High hardness of thin film coating causes high resistance to plastic deformation, low friction coefficient and low specific wear rate.

Article Details

The published articles are copyright of the Engineering Journal of Research and Development, The Engineering Institute of Thailand Under H.M. The King's Patronage (EIT).