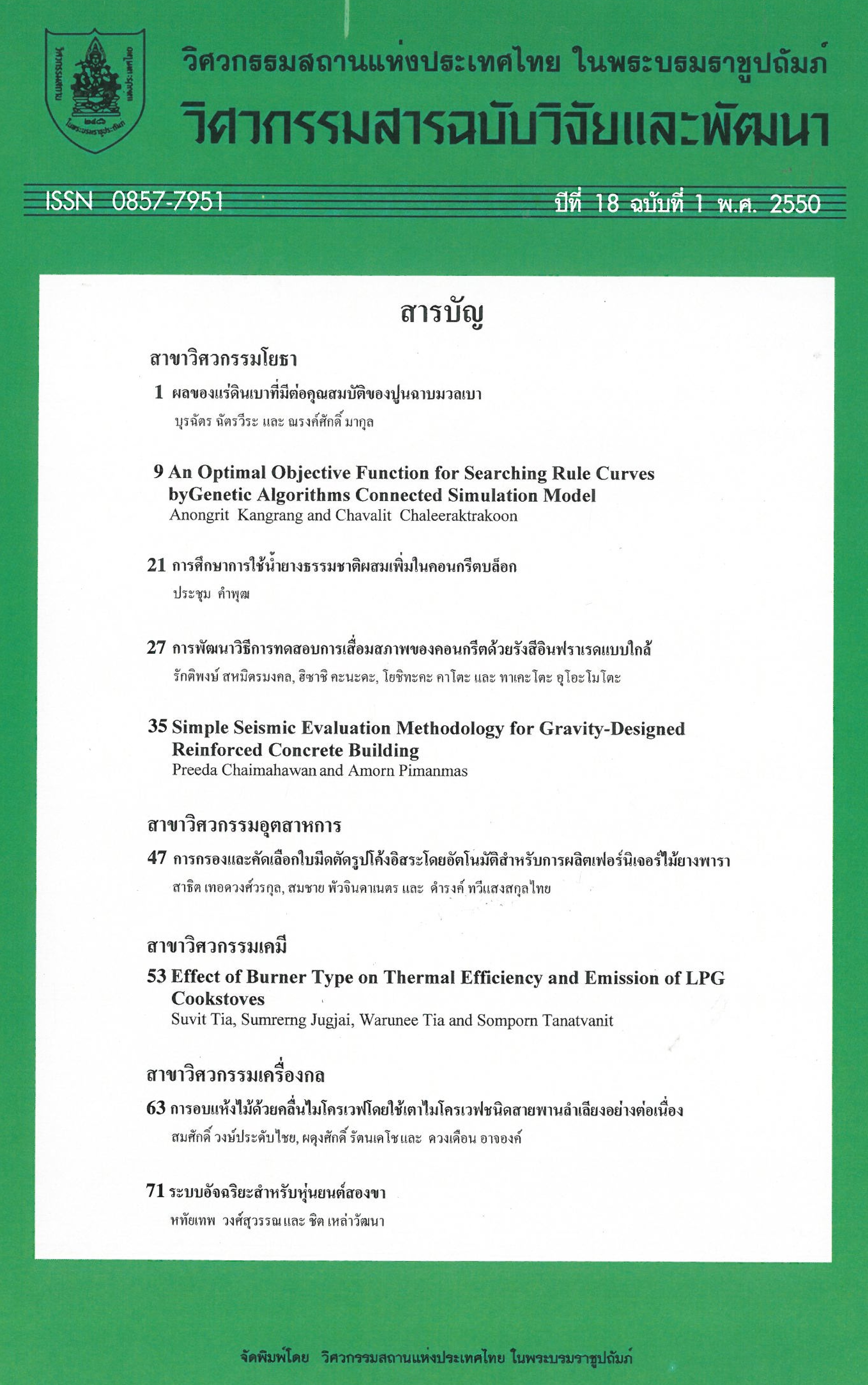

การศึกษาการใช้น้ำยางธรรมชาติผสมเพิ่มในคอนกรีตบล็อก

Main Article Content

Abstract

The aim of this research is to use latex from para rubber mixed in concrete block to develop bending strength and increase thermal insulation properties. The latex to cement (P/C) ratios has been fixed at 0.025, 0.050 and 0.075 by weight. Cement to crushed dust is 1: 4. Water to cement ratio is 0.40 (not include water in para rubber) and 4% (by weight of cement) of nonionic surfactant is also used in the mixture. The concrete block (mixing para rubber) sample is formed by human’s hand with size of 13 × 25 × 14 cm and is tested for water absorption at age of 28 days. Then, it is tested for compressive and bending strengths at ages of 7, 14 and 28 days. Concrete sample 30 × 30 × 25 cm is used to test the thermal conductivity. The results were found that the water absorption of concrete block is reduced when latex to cement ratio is higher. When the latex to cement ratio is increased, the bending strength is increased while the compressive strength is decreased. For the thermal conductivity, it has low values about 0.139-0.188 watt/m-Kelvin and depends on latex to cement ratios. In comparison with the normal concrete block, it is 0.502 watt/m-Kelvin. This means that latex from para rubber could be used an admixture to improve bending strength and thermal insulation of concrete block.

Article Details

The published articles are copyright of the Engineering Journal of Research and Development, The Engineering Institute of Thailand Under H.M. The King's Patronage (EIT).