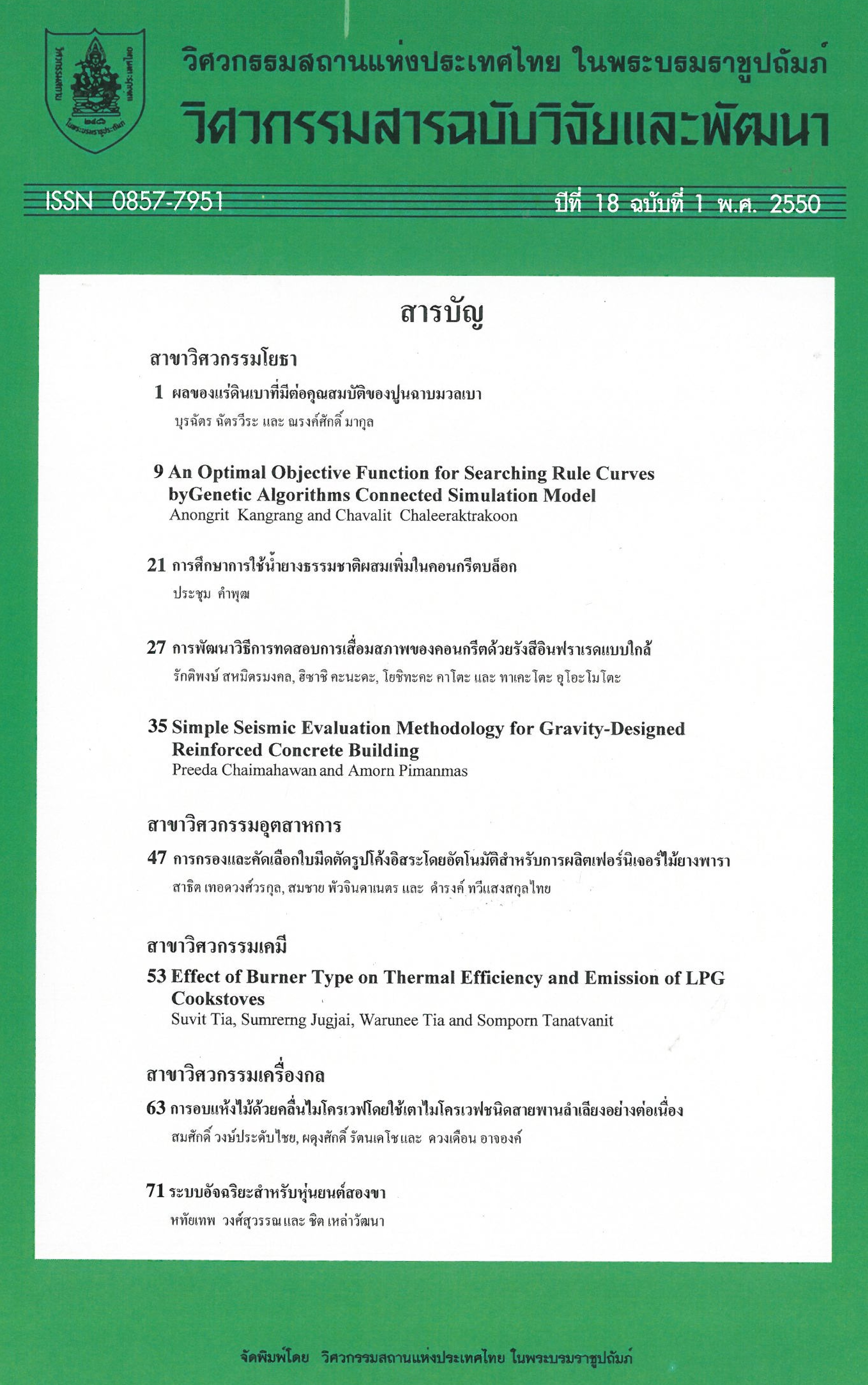

การอบแห้งไม้ด้วยคลื่นไมโครเวฟโดยใช้เตาไมโครเวฟชนิดสายพานลำเลียงอย่างต่อเนื่อง

Main Article Content

Abstract

The drying of wood with microwave energy by using continuous belt furnace was investigated experimentally. Microwave drying was carried out in a microwave continuous belt drier (model MDBT 11.2kW). The drier operates at frequency of 2.45GHz. The microwave power is generated by means of 14 compressed air-cooled magnetrons of 800 watts each for a maximum of 11.2 kW. The power setting can be adjusted individually in 800W steps. The magnetrons are arranged in a spiral around the cylinder cavity. The study focuses on the investigation of the effect of microwave power and the irradiation time on overall drying kinetics, mechanical properties and product quality, i.e., final moisture content and color. After that the final product from microwave drying process is then compared with final product from conventional oven. The results showed that microwave drying has several advantages over the conventional method such as shorter processing times, volumetric dissipation of energy throughout the product and improving mechanical properties. Further quantitative validation of experimental data could be very useful, especially in providing information for processing high performance microwave drying for developing the wood industry in Thailand.

Article Details

The published articles are copyright of the Engineering Journal of Research and Development, The Engineering Institute of Thailand Under H.M. The King's Patronage (EIT).