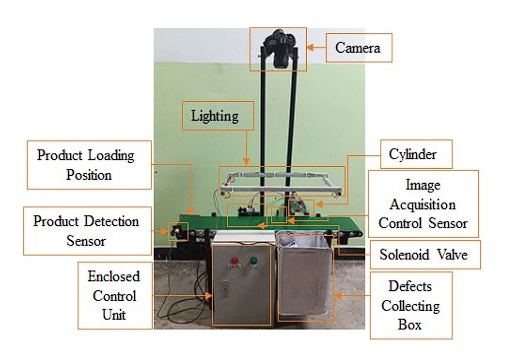

An Empirical Study of the Number of Template Effects on the Efficiency of the Prototype of an Automated Logo Inspection Machine

doi: 10.14456/mijet.2019.12

Keywords:

logo inspection machine, image processing, pattern matchingAbstract

A Product packages have logos printed on them. If these logos were defected, manufacturers may lose customers’ reputation. In addition, the automation increasingly plays an important role in manufacturing process since it can replace human workforce and decrease human errors. Therefore, a prototype of an automated logo inspection machine using pyramidal matching technique was designed and constructed for demonstration and test the efficiency of the proposed logo inspection machine. The original prototype utilized only one image of the package as a template, the experimental results show that the demonstrated machine can distinguish between the complete logos on packages and the defective ones even though the position of the packages were tilted up to ±90 degrees. However, if the package positions were 90 or -90 degrees, the accuracy of the template matching was decreased. Therefore, increasing the number of templates used in the pattern matching algorithm could improve the efficiency of the proposed logo inspection machine by utilizing four templates align in 0, +90, -90, and 180 degree instead of only 0 degree position.

References

URL: http://www.worldbank.org/en/publication/wdr2019, access on 7/6/2019.

[2] Prieto, F., Redarce, T., Lepage, R. et al. (2002), An Automated Inspection System, The International Journal of Advanced Manufacturing Technology. Vol. 19(12), June 2002, pp 917–925.

[3] Reungdist C., Ruenruen P., Jariyatantiwait C. et al. (2019). A Prototype of a Package Checker Using Image Processing, paper (in Thai) presented in the 4th RMUTP Conference of Engineering and Technology, Bangkok, Thailand.

[4] Fawaz Alsaade, (2012). Fast and Accurate Template Matching Algorithm Based on Image Pyramid and Sum of Absolute Difference Similarity Measure. Research Journal of Information Technology, 4: 204-211.

DOI: 10.3923/rjit.2012.204.211

URL:https://scialert.net/abstract/?doi=rjit.2012.204.211

[5] Perveen N., Kumar D. and Bhardwaj I. (2013). An Overview on Template Matching Methodologies and its Applications, International Journal of Research in Computer and Communication Technology, vol. 2(10), October 2013, pp. 988-995.

[6] Mohamed A., Culverhouse P., Cangelosi A., and Yang C. (2018), Depth Estimation Based on Pyramid Normalized Cross-correlation Algorithm for Vergence Control, IEEE Access, vol. 6, pp. 65199 – 65211, November, 2018.

[7] Fouda, Y.M. (2015), A Robust Template Matching Algorithm Based on Reducing Dimensions. Journal of Signal and Information Processing, vol. 6, 109-122. http://dx.doi.org/10.4236/jsip.2015.62011

[8] National Instruments. (2019). Pattern Matching Techniques,

URL:http://zone.ni.com/reference/en-XX/help/370281AE-01/nivisionconcepts/pattern_matching_techniques/, access on 1/6/2019.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2019 Mahasarakham International Journal of Engineering Technology

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.