Optimal Energy of Glutinous Rice Drying via Infrared Irradiation

doi: 10.14456/mijet.2019.8

Keywords:

Infrared, Glutinous rice, Moisture, Energy, Rice CrackersAbstract

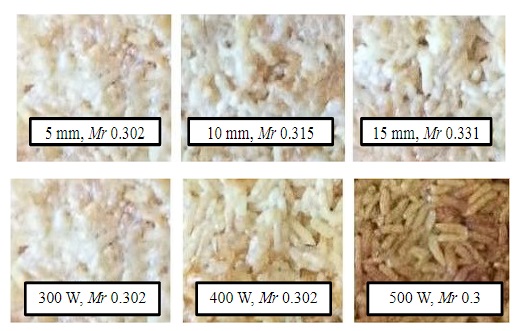

This work aims to study the energy consumption of glutinous rice drying via infrared irradiation. An experimentation was used an infrared heater, with the power adjusted at 300, 400 and 500 W. Parameters were studied on layer’s thickness of glutinous rice, moisture ratios and energy. An experimental result revealed that a drying energy consumption of 0.75 kWh with glutinous rice at 5 mm of layer’s thickness which was optimal. The power was selected at 300 W using a drying time of 150 min.

References

[2] Moon, J.H., Kim, M.J., Chung, D.H., Pan, C.H. and Yoon, W.B. (2014). Drying Characteristics of Sea Cucumber (Stichopus japonicas Selenka) Using Far Infrared Radiation Drying and Hot Air Drying, Journal of Food Processing and Preservation, vol. 38(4), August 2014, pp. 1534–1546.

[3] Dongbang, W. and Matthujak, A. (2013). Anchovy drying using infrared radiation, American Journal of Applied Sciences, vol. 10(4), April 2013, pp. 353–360.

[4] Antal, T. and Kerekes, B. (2016). Investigation of Hot Air- and Infrared-Assisted Freeze-Drying of Apple, Journal of Food Processing and Preservation, vol. 40(2), April 2016, pp. 257–269.

[5] Aidani, E., Hadadkhodaparast, M. and Kashaninejad, M. (2016). Experimental and modeling investigation of mass transfer during combined infrared‐vacuum drying of Hayward kiwifruits, Food Science and Nutrition, vol. 5(3), October 2016, pp. 596–601.

[6] Samadi, S.H. and Loghmanieh, I. (2013). Evaluation of energy aspects of apple drying in the hot-air and infrared dryers, Energy Research Journal, vol. 4(1), August 2013, pp. 30–38.

[7] Swasdisevi, T., Devahastin, S., Ngamchum, R., and Soponronnarit, S. (2007). Optimization of a drying process using infrared-vacuum drying of Cavendish banana slices, Songklanakarin Journal of Science and Technology, vol. 29(3), June 2007, pp. 809–816.

[8] Chayjan, R.A., Kaveh, M. and Khayati, S. (2014). Modeling some drying characteristics of sour cherry (Prunus cerasus L.) under infrared radiation using mathematical models and artificial neural networks, Agricultural Engineering International: CIGR Journal, vol. 16(1), March 2014, pp. 265–279.

[9] Safary, M. and Chayjan, R.A. (2016). Optimization of Almond Kernels Drying under Infrared-vacuum Condition with Microwave Pretreatment using Response Surface Method and Genetic Algorithm, Journal of Agricultural Science and Technology, vol. 18(6), November 2016, pp. 1543–1556.

[10] Posom, J. and Sirisomboon, P. (2015). Evaluation of the moisture content of Jatropha curcas kernels and the heating value of the oil-extracted residue using near-infrared spectroscopy, Biosystems Engineering, vol. 130(Supplement C), February 2015, pp. 52–59.

[11] Chen, N.N., Chen, M.Q., Fu, B.A. and Song, J.J. (2017). Far-infrared irradiation drying behavior of typical biomass briquettes, Energy, vol. 121, February 2017, pp. 726–738.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2019 Mahasarakham International Journal of Engineering Technology

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.