Simulation of Temperature Distribution in Biochar Kiln with Different Feedstock Types

doi: 10.14456/mijet.2019.9

Keywords:

Biochar, Feedstock, Pyrolysis, Simulation, Thermal characteristicsAbstract

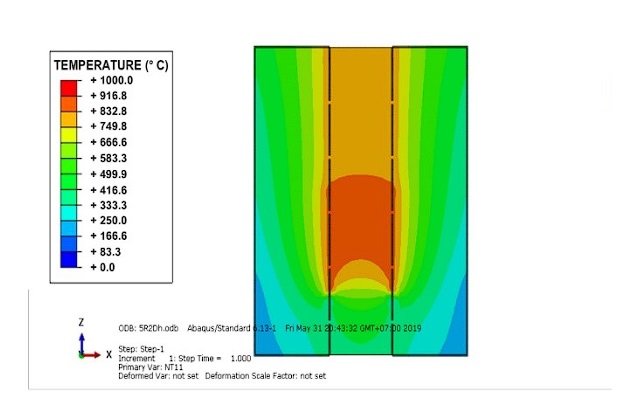

Biochar has been used as a soil fertility improvement. It is a stable carbon-rich solid product obtained from the thermal pyrolysis of organic matter. This work aimed at evaluating the temperature distribution in biochar kiln characterized by the pyrolysis feedstocks. The biochar yield was used to identify the potential of the pyrolysis feedstocks for biochar production. The different pyrolysis feedstock types (i.e., corncob, rice husk, and dry longan leaf) were investigated in this study. The biochar kiln with a dimension of 500 mm × 380 mm (height × diameter) consisting of the core with diameter of 115 mm and puncture diameter of 6.35 mm was developed. The computer simulation was applied and the simulation results were compared with the experimental results in order to validate the model. The simulation results illustrated that the highest temperature was found at the core and transversely decreased in radial direction to the kiln wall. The temperature averagely over the radial and longitudinal positions inside the kiln was found to be equal to 293.3 ± 176.7 °C, 363.4 ± 270.9 °C, and 369.6 ± 277.1 °C and biochar yield was found to be equal to 15.7 wt.%, 24.3 wt.%, and 11.4 wt.% for corncob, rice husk, and dry longan leaf, respectively. These findings indicated that the kiln parameters could be properly developed to satisfy the feedstock types since their temperature distribution could affect the biochar yield.

References

[2] Sohi, S.P., Krull, E., Lopez-Capel, E. and Bol, R. (2010). A review of biochar and its use and function in soil, in Advances in Agronomy, D.L. Sparks, Ed. Burlington: Academic Press, pp. 47-82.

[3] Chen, D., Yu, X., Song, C., Pang, X., Huang, J. and Li, Y. (2016). Effect of pyrolysis temperature on the chemical oxidation stability of bamboo biochar, Bioresource Technology, vol. 218, October 2016, pp. 1303-1306.

[4] Demirbas, A. (2004). Effects of temperature and particle size on bio-char yield from pyrolysis of agricultural residues, Journal of Analytical and Applied Pyrolysis, vol. 72, November 2004, pp. 243-248.

[5] Liu, X., Zhang, Y., Li, Z., Feng, R. and Zhang, Y. (2014). Characterization of corncob-derived biochar and pyrolysis kinetics in comparison with corn stalk and sawdust, Bioresource Technology, vol. 170, October 2014, pp. 76-82.

[6] Budai, A., Wang, L., Gronli, M., Strand, L.T., Antal, Jr., M.J., Abiven, S., Dieguez-Alongso, A., Anca-Couce, A. and Rasse, D.P. (2014). Surface properties and chemical composition of corncob and miscanthus biochars: Effects of production temperature and method, Journal of Agricultural and Food Chemistry, vol. 62, April 2014, pp. 3791-3799.

[7] Shaaban, A., Se, S.M., Dimin, M.F., Juoi, J.M., Husin, M.H.M. and Mitan, N.M.M. (2014). Influence of heating temperture and holding time on biochars derived from rubber wood sawdust via slow pyrolysis, Journal of Analytical and Applied Pyrolysis, vol. 107, May 2014, pp. 31-39.

[8] Suliman, W., Harsh, J.B., Abu-Lail, N.I., Fortuna, A.M., Dallmeyer, I. and Garcia-Perez, M. (2016). Influence of feedstock source and pyrolysis temperature on biochar bulk and surface properties, Biomass and Bioenergy, vol. 84, January 2016, pp. 37-48.

[9] Zhang, J., Liu, J. and Liu, R. (2015). Effects of pyrolysis temperature and heating time on biochar obtained from the pyrolysis of straw and lignosulfonate, Bioresource Technology, vol. 176, January 2015, pp. 288-291.

[10] Yuan, J.H., Xu, R.K. and Zhang, H. (2011). The forms of alkalis in the biochar produced from crop residues at different temperatures, Bioresource Technology, vol. 102, February 2011, pp. 3488-3497.

[11] Panyoyai, N., Wongsirsamuay, T. and Khamdaeng, T. (2018). Temperature distribution inside biochar kiln for biochar production, paper presented in the 10th International Conference on Sciences, Technology and Innovation for Sustainable Well-Being (STISWB 2018), Vientiane, Lao PDR.

[12] Logan, D.L. (2007). A First Course in the Finite Element Method, 4th edition, ISBN: 0-534-55298-6, Nelson, Ontario.

[13] Biswas, B., Pandey, N., Bisht, Y., Singh, R., Kumar, J. and Bhaskar, T. (2017). Pyrolysis of agricultural biomass residues: Comparative study of corncob, wheat straw, rice straw and rice husk, Bioresource Technology, vol. 237, August 2017, pp. 57-63.

[14] Mary, G.S., Sugumaran, P., Niveditha, S., Ramalakshmi, B., Ravichandran, P. and Seshadri, S. (2016). Production, characterization and evaluation of biochar from pod (Pisum sativum), leaf (Brassica oleracea) and peel (Citrus sinensis) wastes, International Journal of Recycling of Organic Waste Agriculture, vol. 5, March 2016, pp. 43-53.

[15] Shariff, A., Noor, N.M., Lau, A. and Ali, M.A.M. (2016). A comparative study on biochar from slow pyrolysis of corn cob and cassava wastes, International Journal of Biotechnology and Bioengineering, vol. 10, December 2016, pp. 767-771.

[16] Sun, Y., Gao, B., Yao, Y., Fang, J., Zhang, M., Zhou, Y., Chen, H. and Yang, L. (2014). Effects of feedstock type, production method, and pyrolysis temperature on biochar and hydrochar properties, Chemical Engineering Journal, vol. 240, March 2014, pp. 574-578.

[17] Saqib, N.U., Oh, M., Jo, W., Park, S.K. and Lee, J.Y. (2017). Conversion of dry leaves into hydrochar through hydrothermal carbonization (HTC), International Journal of Recycling of Organic Waste Agriculture, vol. 19, January 2017, pp. 111-117.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2019 Mahasarakham International Journal of Engineering Technology

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.