Cissus quadrangularis dryer

doi: 10.14456/mijet.2020.10

Keywords:

cissus quadrangularis, cissus quadrangularis dryer, infrared dryer, herb dryer, dryerAbstract

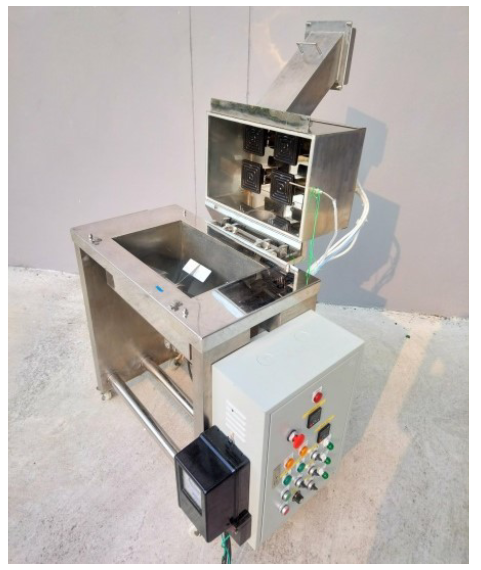

Cissus quadrangularis is a herb of Thailand. It used for many ailments, especially for the treatment of hemorrhoid. This article proposes the designing and construction of the cissus quadrangularis dryer for herbal medicines production. The dryer consists of 4 parts: drying cabinet, infrared heater, motor and blower. In the drying cabinet contains 4 paddles stirrer to stir the herbs for the good heat transfer and ventilation. The suitable drying condition was found by drying at different drying temperature (60°C , 75°C and 90°C) with varying 3 different round speed of paddles stirrer (15 rpm, 25 rpm and 35 rpm). The testing result showed that the suitable drying condition of this dryer occurred in 25 rpm of the paddles stirrer round speed and 90 ˚C of drying temperature which provided the best product’s quality comparing for color, productivity and energy consumption of product.

References

A. Panthong, W. Supraditaporn, D. Kanjanapothi, T. Taesotikul and V. Reutrakul, “Analgesic, Anti-Inflammatory and Venotonic Effects of Cissus Quadrangularis Linn., Journal of Ethnopharmacology, vol. 110, No.2, pp. 264 – 270, March 2007.

Maywisa, Cissus quadrangularis L, Technologychaoban Thailand, https://www.technologychaoban.com/thai-local-wisdom/article_10092, 2017.

The Marketplace of The Industry Photonics buyers’ guide, Colorimetry: How to Measure Color Differences, http://www.photonics.com/Articles/Colorimetry_How_to_Measure_Color_Differences/a25124, 2019.

P. Arlabosse, S. Chavez and D. Lecomte, Method for Thermal Design of Paddle Dryers: Application to Municipal Sewage Sludge, Drying Technology, vol. 22, no. 10, pp. 2375-2393, 2004.

M. Kwapinska, G. Saage and E. Tsotsas, “Mixing of Particles in Rotary Drums: A Comparison of Discrete Element Simulations with Experimental Results and Penetration Models for Thermal Processes,” Powder Technology, vol. 161, No. 1, pp. 69-78, 2006.

T. Balazs, M. Orvos and L. Tomosy, “Heat and Mass Transfer in an Agitated Contact-Convective Heated Dryer,” Food and Bioproducts Processing, vol. 85, no. 3, pp. 291-297, 2007.

S. Jeon, S. Cho, G. Song and Y. Kim, “Two-phase flow analyses in rotary dryer with agitator,” AIP Conference Proceeding, vol. 1225, no. 1, pp. 375-381, 2010.

T. Poos and M. Orvos, “Heat and Mass Transfer in Agitated, Co-, or Countercurrent Conductive-Convective Heated Drum Dryer,” Drying Technology, vol. 30, no. 13, pp. 1457-1468, 2012.

E. Viola, G. Arcieri, F. Zimbardi, V. Valerio, N. Cerone and U. D. Corato, “Evaluation of a Pilot-Scaled Paddle Dryer for the Production of Ethanol from Lignocellulose including Inhibitor Removal and High-Solids Enzymatic Hydrolysis,” Biotechnology Reports, vol. 9, pp. 38-45, 2016.

D. Horváth, T. Poós and K. Tamás, “Modeling the Movement of Hulled Millet in Agitated Drum Dryer with Discrete Element Method,” Computers and Electronics in Agriculture, vol. 162, pp. 254-268, 2019.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2020 Mahasarakham International Journal of Engineering Technology

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.