The Development of an Eri Cocoon Carding Machine

doi: 10.14456/mijet.2020.5

Keywords:

Eri, Silk, Cocoon, CardingAbstract

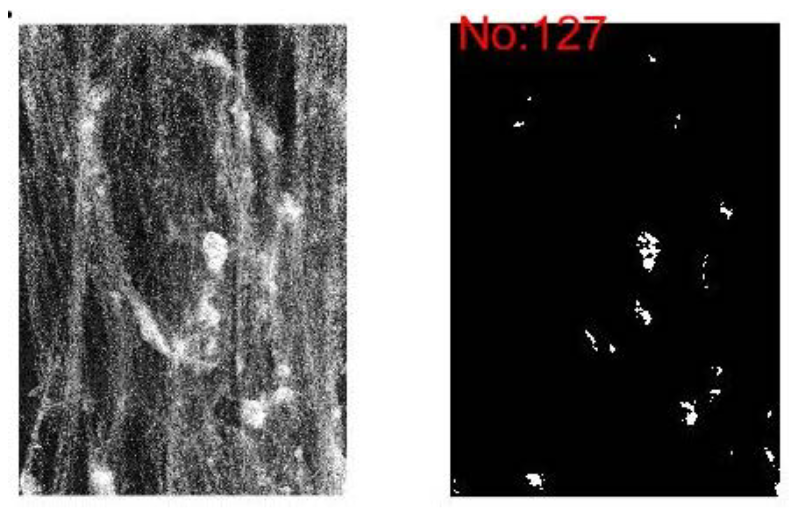

Eri silk is a natural fiber that can be used to make apparel, textiles and develop value added products. Currently, opening Eri cocoon is done by hands, resulting in high time consuming. Product is not enough to meet the needs of the market. In addition, the fiber has a lower rate of silk fiber dispersion. The objective of this project is to develop a cocoon opening machine to increase the cocoon opening rate and provide a high fiber dispersion rate. The development of an Eri cocoon opening machine has added safety equipment, i.e., the cover of the opening head limit switch to cut off the power during the opening head cover or the control cabinet is open. The experiment is divided into 2 main parts, namely, the experiment of opening head type 1 and type 2. From the experiments, it was found that the second opening head provided the best rate of silk fiber dispersion, with an average of 99.8 percent, the cocoon opening rate of 526 grams per hour and can feed a maximum of 50 grams of cocoons sheet. Based on the results of the experiment, it can be concluded that an Eri cocoon opening machine developed in this project can solve the problem of fibers producing for the mulberry growers.

References

S. Sirimungkararat, T. Sangtamat, W. Saksirirat and Y. Waikakul, “New Food Plants for Eri Silkworm Rearing,” International Workshop on Wild Silkmoths and Silk “Current Advances and Development in Wild Silkmoths and Tropical Bombyx Silks, Khon Kaen, Thailand, October 11-14, 2014, pp. 63.

A. R. Horrocks and S. C. Anand, “Handbook of Technical Textiles,” Woodhead Publishing Series in Textiles, 2016.

R. Cholakup, “Yarn Production and Fabric from Eri Mixed with Cotton in Industries,” Report of Research of Development Eri to Industrial Institute of Research and Development of Agriculture and Agro-industry, Kasetsart University, Thailand, 2005.

N. Mahachaiyawong, “Process Development/Tools in Yarn Production and Products of Eri Silk, and Optional Market,” Report of Silk-cotton Project, National Institute of Science Technology, Chaing Mai University, 2001.

D. Brzakovic and N. Vujovic, “Designing A Defect Classification System: A Case Study,” Pattern Recognition, Vol. 29, No. 8, pp. 1401-1419, 1996.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2020 Mahasarakham International Journal of Engineering Technology

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.