Development of a Wireless Sensor Network for Monitoring Husking and Whitening Process in Rice Mills

doi: 10.14456/mijet.2020.19

Keywords:

Husking, Whitening, Rice, Rice mill, Wireless networkAbstract

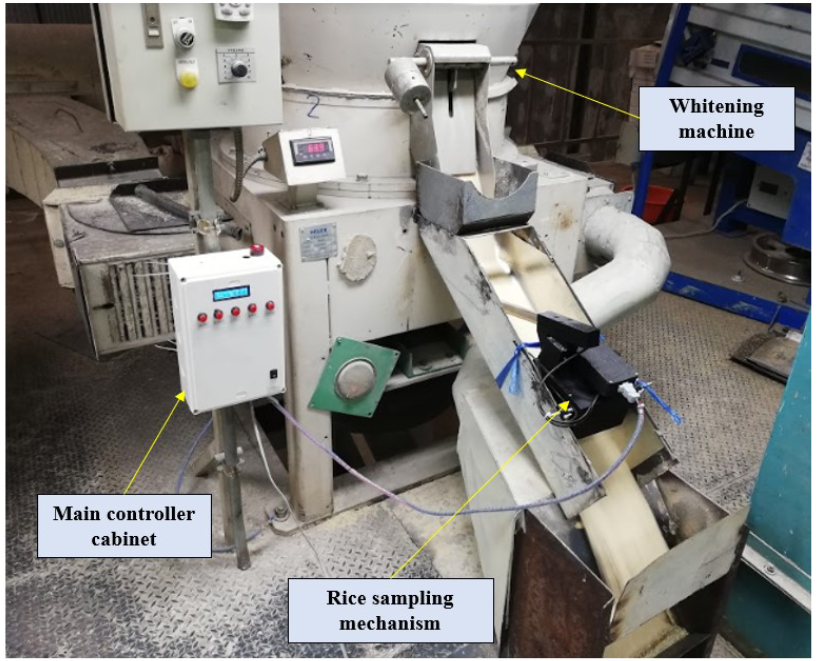

The main machines in rice milling process that affect rice quality are a husking machine and a whitening machine. For instance, the distance between two rubber rolls and the temperature of the rubber rolls in the husking machine have an impact on the husking rate. The temperature and the whiteness of rice grains are used to adjust the whitening machine. Rice grains tend to be broken, if they are whitened excessively or their temperature is extremely high. Due to the above problems, for the husking machine, we developed a monitoring system to detect the wear and the temperature of the rubber roll. Seven distance sensors, 2.5 cm apart, were used to build the surface profile of the rubber roll, while a non-contact temperature sensor was employed to measure the temperature of the rubber roll. The experimental results showed that the errors of the distance sensors were less than 2%. The temperature sensor had an error of less than 1 degree Celsius. For the whitening machine, the rice samples were taken via a sampling mechanism due to high volume flow rate of rice coming out of the machine. The temperature and the whiteness of the rice samples were measured and then they were returned to the next process. The sensor data were transmitted to the office room via a wireless network in order that they were displayed on screen. The alarm located at the office room and in front of the machine was initiated when the temperature or the degree of whiteness was out of the acceptable range. The experimental results showed that the error of the temperature measurement was less than 2 degrees Celsius. The error of the whiteness measurement was less than 2 degrees of whiteness. All data were transmitted via the wireless network, recorded into the database server and displayed on screen correctly.

References

[2] J. Nissayan and A. Artnaseaw, “Increasing an Efficiency of Jasmine Rice Mill,” The 12th National Graduate Research Conference. 2011, vol. 15, pp. 328–336, 2011.

[3] M. R. Alizadeh and M. H. Rahmati, “Effect of paddy dehusking rate in rubber roll sheller on the milling quality of different rice varieties,” Elixir Agriculture. 2011, vol. 39, pp. 4880–4883, 2011.

[4] S. Chusilp, S. Sudajan, P Phunphan and J. Mongkhonwai, “The effects of wear rubber roll huller on the effectiveness of paddy hulling,” Postharvest Technology Innovation Center, 2008.

[5] A. Baker, R. Dwyer-Joyce, C. Briggs, and B. Moris, “Effect of different rubber materials on husking dynamics of paddy rice,” Proceedings Inst. Mech. Eng. J. Eng. Tribol. 2012, vol. 6, no. 226, pp. 516–528, 2012.

[6] S. VAODEE and A. Artnaseaw, “Reducing air temperature in paddy husker process to increase percent of whole grain,” IE Network Conference 2011, pp. 1319–1324, 2011.

[7] J. Nissayan and A. Artnaseaw, “Increasing an Efficiency of husker machine,” TIChE International Conference 2011, vol. 21, pp. 5–8, 2011.

[8] C. Jangkajit and C. Khunboa, “The study of relationship between whiteness and temperature of rice,” Adv. Comput. Inf. Technol. (ACIT 2013), pp. 238–243, 2013.

[9] B. K. Yadav and V. K. Jindal, “Monitoring milling quality of rice by image analysis,” Comput. Electron. Agric., vol. 33, no. 1, pp. 19–33, 2001.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2020 Mahasarakham International Journal of Engineering Technology

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.