Maintenance Work Environment and the Interacting Multidisciplinary Concerns using Multicriteria Techniques

doi: 10.14456/mijet.2021.22

Keywords:

Fuzzy environment, fuzzy entropy weighting approach, FGRAAbstract

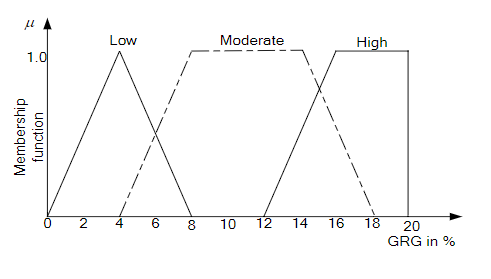

The work environment significantly impacts on the workers' performance in modern-day manufacturing and should be a subject of further investigations for improved manufacturing performance. Nonetheless, the interactions among the physical, organisational and system safety factors remain unclear, amplifying efforts to effectively control the performance of the workforce. In the research, the investigators examined a framework that tests the interaction among fifteen selected factors which indicates work environment. The researchers utilized fuzzy entropy weighting and fuzzy grey relational analysis to develop a model that was tested in four manufacturing systems, using the fifteen factors selected from literature. The investigators conducted normalisation, determination of coefficient for grey relations, membership function determination and class selection procedure with applications to the fifteen factors selected. All maintenance systems had highly conducive environmental aggregates (Company A, Company C and Company D are 0.9400, 0.9442 and 0.8667 respectively) but one failed (Company B=0.7482). This suggests that the three healthy systems can effectively plan for performance improvement programmes such as productivity and quality drives. Work environment plays a crucial function in the corridor of performance analysis of manufacturing concerns. Consequently, the work environmental framework suggested should be a typical appraisal scale for manufacturing systems. Intervention using the proposed framework is necessary to enhance manufacturing system performance. The interactions among the fifteen selected factors of work environment show a healthy status in 75% of the cases considered. The feasibility of modelling the problem using the emerging models of fuzzy-based criteria was confirmed.

References

[2] Pascal V, Tonfik A, Manuel A, Florent D, Frederic K, Improvement indicators for total productive maintenance policy, Control Engineering Practice, Vol. 82, pp. 86–96

[3] Azadeh A., Gaeini Z, Moradi B., 2014, Optimization of HSE in maintenance activities by integration of continuous improvement cycle and fuzzy multivariate approach: A gas refinery, Journal of Loss Prevention in the Process Industries, Vol. 32, pp. 415 – 427

[4] Geng J, Zhou D, Lv C, Wang Z, 2013, A modeling approach for maintenance safety evaluation in a virtual maintenance environment, Computer-Aided Design, Vol. 45, No. 5, pp. 937 – 949

[5] Harper AC, Gunson C, Robinson L, de Klerk NH, Osborn D, Sevastos P, Cordery J.L, Geelhoed E, Sutherland M., Colquhoun J., 1996, Gutin industrial safety trial: Methods and safe practice and housekeeping outcomes, Safety Science, Vol. 24, No.3, pp. 159-172

[6] Kumar G, Kalita K, 2016, Vibration control using BCW induction motor, Procedia Engineering, Vol. 144, pp. 94-101

[7] Razak NA, Ma'amor H, Hassan N, 2016, Measuring reliability and validity instruments of work environment towards quality work-life, Procedia Economics and Finance, Vol. 37, pp. 520-528

[8] Hays J, McCawley M, Shonkoff SBC, 2017, Public health implications of environmental noise associated with unconventional oil and gas development, Science of the Total Environment, Vol. 580, pp. 448-456.

[9] Rubio-Romero JC, Carrillo-Castrillo JA, Soriano-Sewano M, Galindo-Reyes F, de la Varga-Salto J, 2018, A longitudinal study of noise exposure and its effects on the hearing of olive oil mill workers, International Journal of Industrial Ergonomics, Vol. 67,pp. 60-66

[10] Nassiri P, Monazzam MR, Asghari M, Zakerian SA, DehghanSF, Folladi B, Azam K, 2015, The interactive effect of industrial noise type, level and frequency characteristics on occupational shills, Performance Enhancement and Health, Vol. 3, pp. 61-65

[11] Guo L., Li P-H., Li H., Colicino E, Colicino S, Wen Y, Zhang R, Feng X, Barrow TM, Cayir A, Baccarelli AA, Byun H. M., 2017a Effects of environmental noise exposure on DNA methylation in the brain and metabolic health, Environmental Research, Vol. 153, pp. 73-82

[12] Ehleiter A, Jaehn F, 2016, Housekeeping: Foresightful container responding, International Journal of Production Economics, Vol. 179, pp. 203-211

[13] Cordeau J-F, Legato P, Mazza RN, Trunfio R, 2015, Simulation-based optimization for housekeeping in a container transshipment terminal, Computer and Operations Research, Vol. 53, pp. 81-95

[14] Lefebvre X, Trabuc P Liger K, Perrais C, Santucci A, 2012, Preliminary results from a detritiation facility dedicated to soft housekeeping waste, Fusion Engineering and Design, Vol. 87, No 7-8, pp. 1040-1044

[15] Jausan M, Silva J, Sabatini R, 2017, A holistic approach to evaluating the effect of safety barriers on the performance of safety reporting systems in aviation organisations, Journal of Air Transport Management, Vol. 63, pp. 95-107

[16] Oswald D, Sherratt F, Smith S, 2018, Problems with safety observation reporting: A construction industry case, Safety Science, Vol. 107, pp. 35-45

[17] Tanguy L, Tulechki N, Urieli A, Hermann E, Raynal C, 2016, Natural Language processing for aviation safety reports: From classification to interactive analysis, Computers in Industry, Vol. 78, pp 80-95

[18] Angius A, Colledani M, Silipo L, Yemane A 2016, Impact of preventive maintenance on the service level of multi-stage manufacturing systems with degrading machines, IFAC-PapersOnLine, Vol. 49, No. 12, pp. 568-573

[19] Holgado M, Macchi M, Fumagalli L, 2016, Value-in-use of e-maintenance in service provision: survey analysis and future research agenda, IFAC-PapersOnLine, Vol. 49, No. 28, pp. 138-143

[20] Bokrantz J, Skoogh A, Berlin C, Stahre J 2017, Maintenance in digitalised manufacturing: Delphi-based scenarios for 2030, International Journal of Production Economics, Vol. 191, pp. 154-169

[21] Angius A, Colledani M, Yemane A 2018, Impact of condition based maintenance policies on the service level of multi-stage manufacturing systems, Control Engineering Practice, Vol. 76, pp. 65-78

[22] Hassim M, 1984 Reliability concepts applied to service industries, International Journal of Quality and Reliability Management, Vol. 1, No. 1, pp. 39-50

[23] Goh M, Tay G-H, 1995, Implementing a quality maintenance system in a military organization, International Journal of Quality and Reliability Management, Vol. 12, No. 4, pp. 26-39

[24] Bartolini M, Bevilacqua M, Braglia M, Frosolini M, 2004, An analytical method for maintenance outsourcing service selection, International Journal of Quality and Reliability Management, Vol. 21, No. 7, pp. 772-788

[25] Ab-Wahib R, Corner J, Tan P-L, 2011 ISO 9000 maintenance in service organizations; tales from two companies, International Journal of Quality and Reliability Management, Vol. 28, No. 7, pp. 735-757

[26] Desselle SP, Andrews B, Lui J, Roja GL, 2017, The scholarly productivity and work environments of academic pharmacists, Research in Social and Administrative Pharmacy, in press, pp. 1-9

[27] Karimi A., Ahmadpour B, Marjani M.R., 2018, Using the fuzzy grey relational analysis method in wastewater treatment process selection, Iranian Journal of Health, Safety and Environment, Vol.5, pp. 1041 – 1050

[28] Goyal S. and Grover S., 2012, Applying fuzzy grey relational analysis for ranking the advanced manufacturing systems, Grey Systems: Theory and Application, Vol.2, No.2, pp. 284–298

[29] Azzeh M., Neagu D., Cowling P.I., 2010, Fuzzy grey relational analysis for software effort estimation, Empirical Software Engineering, Vol. 15, No.1, pp.60–90

[30] Tamiloli N., Venkatesan J., Rammath B.V., 2016, A grey – fuzzy modeling for evaluating surface roughness and material removeal rate of coated end milking insert, Measurement, Vol. 84, pp.68 – 82

[31] Joshi P. and Sharma A., 2018, simultaneous optimization of kerf taper and heat affected zone in Nd – YAG laser cutting of Al 6061 – T6 sheet using hybrid approach of grey relational analysis and fuzzy logic, Precision Engineering, Vol.54, pp.302 – 313

[32] Zhou J. Wang Y, Li B, 2012, study on optimization of denitration technology based grey – fuzzy comprehensive evaluation model, Systems Engineering, Procedia, Vol.4, pp. 210 – 218

[33] Kumaran S.T., Ko TJ, Kurniawan R, 2018, Grey fuzzy optimization of ultrasonic – assisted EDM process parameters for deburring CFRP composites, Measurement, Vol.123, pp.203 – 212

[34] Pandey RK and Panda S.S, 2014, Optimisation of bone drilling parameters using grey – based fuzzy algorithm, Measurement, Vol.47, pp.386 – 392

[35] Shunmugesh K, Akhil K.T., Aravind S., Pramodkumar M, 2017, Optimisation of drilling characteristics using grey – fuzzy logic in glass fiber reinforced polymer (GFRP), Materials Today: Proceedings, Vol.4, pp. 8938 – 8947

[36] Huang Y – P and Chu H – C, 1999, Simplifying fuzzy modeling by both grey relational analysis and data transformation methods, Fuzzy Sets and Systems, Vol.104, pp.183 – 197

[37] Zhou Q. and Thai V.V., 2016, Fuzzy and grey theories in failure mode and effect analysis for tanker equipment failure prediction, Safety Science, Vol. 83, pp. 74 – 79

[38] Wang H., Duanmu L., Lahdelma R, Li X, 2018, A fuzzy–grey multicriteria decision making model for district heating system, Applied Thermal Engineering, Vol. 128, pp. 1051 – 1061

[39] Palanisamy D, and Senthil P, 2018, Application of CNC turning process, Materials Today: Proceedings, Vol.5, pp. 6645 –6654

[40] Prakash O., Sharma P.K., Mahajan R., 2008, New measures of weighted fuzzy entropy and their applications for the study of maximum weighted fuzzy entropy principle, Information Sciences, Vol.178, No.11, pp. 2389–2395

[41] Qi Y., Wen F, Wang K, Li L, Singh S.N., 2010, A fuzzy comprehensive evaluation and entropy weight decision – making based method for power network structure assessment, International Journal of Engineering, Scientific and Technology, Vol.2, No.5, pp.92–99

[42] Zimmermann, H.-I., and Zysno, P. 1980. Latent connectives in human decision making, Fuzzy Sets and Systems, Vol. 4, pp. 37-51.

[43] Yager R. R. 1993. Families of OWA operators. Fuzzy Sets and Systems, Vol. 59, No. 2, pp. 125-148.

[44] Auger N, Duplaix M, Bilodeau-Bertrand M, Lo E, Smargiassi A 2018, Environmental noise pollution and risk of preeclampsia, Environmental Pollution, Vol. 239, pp. 599-606

[45] Jiang J., Li Y, 2018, Review of active noise control techniques with emphasis on sound quality enhancement, Applied Acoustics, Vol. 136, pp. 139-148

[46] Song P and Zhao H, 2018, Filtered-x generated mixed worm (FXGMN) algorithm for active noise control, Mechanical Systems and Signal Processing, Vol. 107, pp. 93-104

[47] Lam B., Elliott S, Cheer J., Gan W-S, 2018, Physical limits on the performance of active noise control through open windows, Applied Acoustics, Vol. 137, pp. 9-17

[48] Mezyk A, Klein W, Pawlak M, Kania J, 2017, The identification of the vibration control system parameters designed for continuous Miner machines, Journal of Non-Linear Mechanics, Vol. 91, pp. 181-188

[49] Zhang Y-W, Hou S, Xu K-F, Yang T-Z, Chen L-Q, 2017, forced vibration control of an axially moving beam with an attached nonlinear energy sink, Acta Mechanical SolidaSinica, Vol. 30, No. 6, pp. 674-682

[50] Rahmani B, Shenas AG, 2017, Robust vibration control of laminated rectangular composite plates in hygrothermal and thermal environment, Composite Structures, Vol. 179, pp. 665-681

[51] Ning D., Sun S, Du H, Li W, Zhang N, 2018, Vibration control of an energy regenerative seat suspension with variable external resistance, Mechanical Systems and Signal Processing, Vol. 106, pp. 94-113.

[52] Xie Y, Shi H, Bi F, Shi J, 2018, A MIMD data-driven control to suppress structural vibration, Aerospace Science and Technology, Vol. 77, pp. 429-438

[53] Tombari A, Espinosa M.G, Alexander NA, Cacciola P., 2018, Vibration control of a cluster of buildings through the vibrating barrier, Mechanical Systems and Signal

[54] Xue K, Igarashi A, Kachi T, 2018, Optimal sensor placement for active control of floor vibration considering spillover effect associated with modal filtering, Engineering Structures, Vol. 165, pp. 198-209.

[55] Dufort V.M, Infante-Rivard C, 1999, Measuring housekeeping in manufacturing industries, The Annals of Occupational Hygiene, Vol. 43, No. 2, pp. 91-97

[56] Leivo A, 2005, Field study of the effects of a self-implemented feedback program on housekeeping performance, International Journal of Industrial Ergonomics, Vol. 35, No. 5, pp. 471-485.

[57] Aker E, Patoglu V, Erdem E, 2012, Answer set programming for reasoning with semantic knowledge in collaborative housekeeping robotics, IFAC Proceedings Volumes, Vol. 45, No 22, pp. 77-83

[58] Liger K, Trabuc P, Mascarde J, Troulay M, Borgogoni F, 2014, Preliminary results from a detritiation facility dedicated to soft housekeeping waste and tritium valorization, Fusion Engineering and Design, Vol. 89, Nos 9-10, pp. 2103-2107

[59] Paltrinieri N, Tugnoli A, Cozzani V., 2015, Hazard identification for innovative LNG regasification technologies, Reliability Engineering and System Safety, Vol. 137, pp. 18-28.

[60] Xin P, Khan F, Ahmed S., 2017, Dynamic hazard identification and scenario mapping using Bayesian Network, Process Safety and Environmental Protection, Vol. 105, pp. 143-155

[61] Camenon I., Mannan S, Nemeth E, Park S, Pasinan H, Rogers W, Selimann B, 2017, Process hazard analysis, hazard identification and scenario definition: Are the conventional tools sufficient, or should and can we do much better? Process Safety and Environmental Protection, Vol. 110, pp. 53-70

[62] de Galvez N, Marsot J, Martin P, Siadat A, Etienne A, 2017, EZID: A new approach to hazard identification during the design process by analyzing energy transfers, Safety Science, Vol. 95,pp. 1-14

[63] Moren VC, Cozzani V, 2018, Integrated hazard identification within the risk management of industrial processes, Safety Science, Vol. 103, pp. 340-351

[64] Strauch B, 2015, Can we examine safety culture in accident investigations, or show we? Safety Science, Vol. 77, pp. 102-111

[65] Hasani H., Tabatabaei S.A. and Amiri G. (2012). Grey relational analysis to determine the optimum process parameters for open-end spinning yarns. Journal of Engineered Fibers and Fabrics. Vol. 7, No. 2, pp. 81-86.

[66] Iung B, Levrat E 2014, Advanced maintenance services for promoting sustainability, Procedia CIRP, Vol. 22, pp. 15-22

[67] Sari E, Shaharoun AM, Ma'aram A, Yazid AM 2015, Sustainable maintenance performance measures: a pilot survey in Malaysian automotive companies, Procedia CIRP, Vol. 26, pp. 443-448

[68] Salikin N, Ab Wahab N, Muhammad I 2014, Strengths and weaknesses among Malaysian SMEs: Financial management perspectives, Procedia - Social and Behavioral Sciences, Vol. 129, pp. 334-340

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2021 Engineering Access

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.