A Green Preventive Maintenance Model Incorporating the Green Fuzzy Deployment Method with the WASPAS Approach for Production Lines

doi: 10.14456/mijet.2022.3

Keywords:

Green quality function deployment, WASPAS, sustainability, fuzzy entropy weighting approach, preventive maintenance requirementsAbstract

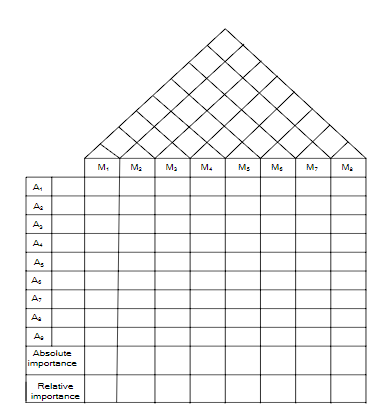

Preventive maintenance assessments are presently obligatory on production lines as they reduce unscheduled downtime requiring major equipment repairs and aid improved asset conservation and the life expectancy of assets. However, the present preventive maintenance models are deficient as they exclude essential environmentally conscious design and manufacturing elements to produce customer-oriented green preventive maintenance programmes. In this paper, the idea is to use the green design principles and then incorporate the voice of customers and producers concurrently to design the preventive maintenance programme in a production line. The proposed green quality function deployment model is based on the philosophy of customers’ needs and aspirations, which drive the preventive maintenance programme. At the same time, the manufacturer is compelled to comply with these needs from the perspectives of cost, technical competence and other issues. The WASPAS multi-criterion model is then employed to and the selection process. The applicability of the proposed framework was tested using information obtained from a cement production plant. Three production lines were considered. Based on the results obtained from the case study, the most important requirement for determining the rank of the production lines was the physical life of the equipment. Maintenance workforce cost is the least important requirement for determining the production lines ranks. The results from the WASPAS method showed that production lines 2 and 1 had the highest and least ranking, respectively. The usefulness of this attempt is to help maintenance managers to install effective decisions preventive maintenance programmes at lower costs and zero liability to the company regarding litigation claims.

References

2. Dietz D.C. and Rosenshine M. (1997). Optimal specialisation of a maintenance workforce. IEEE Transactions, Vol. 27, pp. 423-433.

3. Dong C., Zhang C. and Wang B. (2003). Integration of green quality function deployment and fuzzy multi-attribute utility theory-based cost estimation for environmentally conscious product development. International Journal of Environmentally Conscious Design and Manufacturing, Vol. 11, No. 1, pp. 12-28.

4. Human Capital Management Institute (HCMI) (2014). Managing an organisation biggest cost: The workforce. Available at http://www.orgplan.eu/OrgPlanPDF.php (accessed April 15, 2014).

5. Ighravwe, D.E., and Oke, S.A. (2014). A nonzero integer nonlinear programming model for maintenance workforce sizing. International Journal of Production Economics, Vol. 150, pp. 204-214.

6. Kazmi S. and Naaranoja M. (2013). Connecting individual differences in workforce of organisational creativity through transformational leadership for corporate transformational effectiveness. Open Journal of Leadership, Vol. 2, pp. 73-77.

7. Kronos (2014). Overall labour effective: Achieving a highly effective workforce. Available at www.kronos.com (accessed January 24, 2014).

8. Mansour M.A.A-F. (2011). Solving the periodic maintenance scheduling problem via genetic algorithm to balance workforce levels and maintenance cost. American Journal of Engineering and Applied Sciences, Vol. 4, No. 2, pp. 223-234 .

9. Masui K. Sako T., Kobayashi M. and Inaba A. (2003). Applying quality function deployment to environmentally conscious design. International Journal of Quality and Reliability Management, Vol. 20, No. 1, pp. 90-106.

10. Shemshadi A., Shirazi H., Toreihi M. and Tarokh M.J. (2011). A fuzzy VIKOR method for supplier selection based on entropy measure for objective weighting. Expert Systems and Application, Vol. 38, pp. 12160-12167.

11. Šaparauskas J., Zavadskas E.K. and Turskis Z. (2011). Selection of facade’s alternatives of commercial and public buildings based on multiple criteria. International Journal of Strategic Property Management, Vol. 15, No. 2, pp. 189-203.

12. Yang Y.Q., Wang S.Q., Dulaimi M. and Low S.P. (2003). A fuzzy quality function deployment system for buildable design decision-makings. Automation in Construction, Vol. 12, pp. 381-393.

13. Zahedi M.R., Yousefi S. and Chehmberah M. (2011). A fuzzy quality function deployment approach to enterprise resource planning software selection. Asian Journal of Scientific Research, Vol. 4, No. 2, pp. 114-128.

14. Zavadskas E.K., Turskis Z., Antucheviciene J. and Zakarevicius A. (2012). Optimisation of Weighted Aggregated Sum Product Assessment. Electronics and Electrical Engineering, Vol. 6, No. 122, pp. 3-6.

15. Karabašević D., Stanujkić D., Urošević S. and Maksimović M. (2016). AN approach to personnel selection based on SWARA and WASPAS methods. Journal of Economics, Management and Informatics, Vol. 7, No. 1, pp. 1-11.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2021 Engineering Access

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.