The Thermal Foaming of Solid Sodium Silicate for Thermo-Sensing Applications

doi: 10.14456/mijet.2021.16

Keywords:

Sodium silicate, thermal foaming, phase transformation, amorphous, thermal switchAbstract

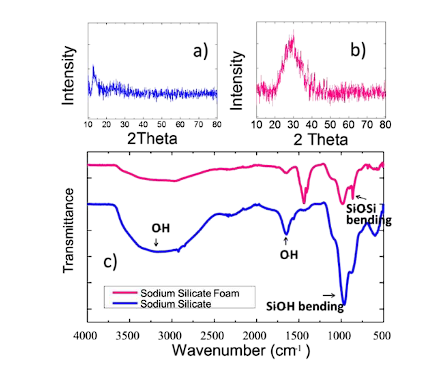

Sodium silicate solution was dried and slowly solidified in amorphous phase. After heat was supplied, the dried solid sodium silicate droplet transformed to sodium silicate foam without the liquid boiling mechanism. During the solid state foam formation, the amorphous phase is deformed and partially recrystallized. The structure of foam grows in semi 2 dimensions and become a thin bubble crust. This transformation was anisotropic, and depended on the heating rate. The residual water in solid sodium silicate played a major role in the foaming mechanism. The solid form of sodium silicate is highly portable and be functionalized as devices. It was integrated in thermo-sensing applications such as fire alarm sensor and autovent by using the property of the large volume expansion.

References

[2] S. Shaker, 2005. Committee, Drilling Fluids Processing Handbook 700, Elsevier, 1st edn.

[3] Slimak, K.M., Slimak, R.A., 2001US Patent 6303234B1.

[4] Baker Jr, E.J., Mallow, W.A., 1968. in Silicate Foam for Airdrop Cushioning, (Defense Technical Information Center,).

[5] J. Acocella,M. Tomozawa, E. B. Watson, The nature of dissolved water in sodium silicate glasses and its effect on various properties, J. https://doi.org/10.1016/0022-3093(84)90058-9.

[6] S.A. Greenberg, The Nature of the Silicate Species in Sodium Silicate Solutions, J. Am. Chem. Soc. 80(1958) 6508-6511. https://doi.org/10.1021/ja01557a011.

[7] H.I. Hoffman, Sodium silicate as a versatile structural material, Contrail, (1965)289-303. http://contrails.iit.edu/DigitalCollection/1965/AFAPLTR65-108article14.pdf (Accessed: 04.09.15)

[8] I. Tsuyumoto, A Novel Sodium Silicate Fluoride Solution and a H2 Gas Formed by a Reaction Between Si and an Aqueous Solution of NaOH and NaF, J. Am. Ceram. Soc. 88(2005)1628-1630. https://doi.org/10.1111/j.1551-2916.2005.00254.x.

[9] Sams, H., McCready, A., McCready, NW., 1968. US Patent 3579299.

[10] Durian, D.J., Weitz, D.A., Pine, D.J., 1991. Multiple light-scattering probes of foam structure and dynamics, Science, 252, 686-688.

[11] Subasri, R., Näfe, H., 2008. Phase evolution on heat treatment of sodium silicate water glass, Non-Cryst. Solid., 354, 896-900.

[12] Y. Wang, M. Yu, Q. Qiao, F. You, C. Li, Z. Xu, K. Matsugi, J. Yu, Effect of Plastic Deformation on the Crystal Structure and Crystallization Activation Energy of Ni-W-P Alloy Coating J. Mater. Eng. Perform. 24 (2015) 2653-2657.

[13] S.G. Oleinik, N.V. Danilenko, Primary recrystallization mechanisms in ceramic materials Powder Metall Met C+ 37 (1998) 55-66.

[14] A.K. Pant, A reconsideration of the crystal structure of b-Na2Si2O5, Acta Cryst., B24 (1968) 1077.

[15] X. Zhang, W. Sun, H. Ma, H. Xu, J. Dong, Investigation of the Tribological Properties of Two Different Layered Sodium Silicates Utilized as Solid Lubrication Additives in Lithium Grease. Ind. Eng. Chem. Res. 53 (2014) 182-8.

[16] HUYNEN, I., VANHOENACKER-JANVIER, D., VANDER VORST, A. Spectral domain form of new variational expression for very fast calculation of multilayered lossy planar line parameters. IEEE Transactions on Microwave Theory and Techniques, 1994, vol. 42, no. 11, p. 2099 - 2106.

[17] GUPTA, K. C., GARG, R., BAHL, I., BHARTIA, P. Microstrip Lines and Slotlines. 2nd ed. Norwood: Artech House, 1996.

[18] WANG, S., WANG, F., DEVABHAKTUNI, V. K., ZHANG, Q.-J. A hybrid neural and circuit-based model structure for microwave modeling. In Proceedings of the 29th European Microwave Conference. Munich (Germany), 1999, p. 174 - 177.

[19] Schurter AG, Switzerland. 5110 EMI filter (datasheet). 4 pages. [Online] Cited 2008-06-23. Available at: http://www.schurter.cz/¬pdf/english/typ5110.pdf.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2021 Engineering Access

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.