Multiple-Barcode Verification using Image Processing Technique for Mobile Phone Packaging

doi: 10.14456/mijet.2021.23

Keywords:

Multiple-barcode verification, image processing, working time reduction, NI visionAbstract

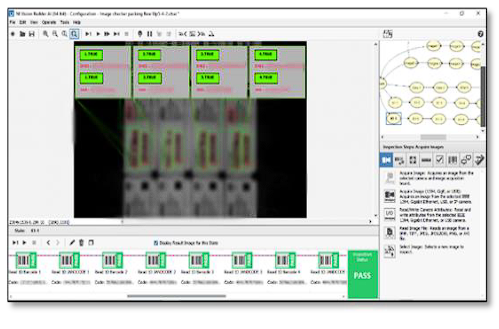

Barcodes play an important role for industrial manufacturing and packaging processes or inspections due to their fast, cheap and relatively high accuracy compared to human’s recognition. However, most barcode readers can read only one barcode at a time while some inspection processes would require multiple barcode reading for saving working time of operators. This research proposes a multiple-barcode verification using the commonly used NI Vision image processing program for mobile phone packaging process. The verification system consists of cameras with a lighter and a NI Vision 2018 image processing program. The program read 8-20 barcodes at a time from a photograph captured by the fixed-position camera. The experimental test results showed that the proposed system spent only 5-7 seconds for 10-barcodes verification, which was faster than the human’s operation with one-by-one scanning (19-27 seconds) and thus save working time by 3-4 times. In addition, the proposed system also provided high accuracy of 98.64%, which was better than human’s operation (94.04%) by 4.60%.

References

[2] Gallo, O., IEEE, Manduchi, R., & Wember, S. (2011). Reading 1D Barcodes with Mobile Phones Using Deformable Templates. IEEE TRANSACTIONS ON PATTERN ANALYSIS AND MACHINE INTELLIGENCE, 33(9), 1834-1843.

[3] Creusot, C., & Munawar, A. (2015). Real-time Barcode Detection in the Wild. IEEE Winter Conference on Applications of Computer Vision, 239-245.

[4] Hansen D., Nasrollahi K., B. Rasmusen C., & Moeslund T. (2017). Real-Time Barcode Detection and Classification using Deep Learning. In Proceedings of the 9th International Joint Conference on Computational Intelligence (IJCCI 2017), 321-327.

[5] NAMANE, A., & AREZKI, M. (2017). Fast Real Time 1D Barcode Detection From Webcam Images Using the Bars Detection Method. Proceedings of the World Congress on Engineering 2017.

[6] Barcode Images Using Edge Detection and Morphological Operation. Priyanka Gaur et al, International Journal of Computer Science and Mobile Computing, April- 2014, 3(4), 1277-1282.

[7] Pak, M., & Kim, S. (2015). 2D Barcode Detection Algorithm with Multiple Features Combination for a Long Distance Search. 2015년 추계학술발표대회 논문집 제22권 제2호(2015. 10), 1506-1508.

[8] Zhang, H., Shi, G., Liu, L., Zhao, M. and Liang, Z. (2018) Detection and identification method of medical label barcode based on deep learning. 2018 Eighth International Conference on Image Processing Theory, 1-6.

[9] Zafar, I. (2010). Real Time Multiple Two Dimensional Barcode Reader. In 5th IEEE Conference on Industrial Electronics and Applicationsis. p. 427-432.

[10] Jittima Varagul. (2010). Development of Automated Visual Inspection Machine for HDD Manufacturing Process, M.Eng. (Mechanical Engineering). Suranaree University of Technology.

[11] Sarkar, A. (2014). Fault idetification on Cigarette Packts-An Image Processing Approach. In Annual IEEE India Conference (INDICON).

[12] Chauhan, A.P.S. (2011, July 6-8). Detection of Bare PCB Defects by Image Subtraction Method using Machine Vision. Proc. Proceedings of the World Congress on Engineering 2011, 1.

[13] Diaz, R., Gil, L., Serrano, C. & Blasco, M. (2004). Comparison of three algorithms in the classification of table olives by means of computer vision. Journal of Food Engineering, 61(1),101-107.

[14] Wisit Lumchanao. (2018). Development of Egg Incubator for Detecting Embryos in Chicken Eggs Using Digital Image Processing Techniques. SWU Engineering Journal, 13(1), 151-165.

[15] Chaki, A., Prashant, M & Sen P. (2010). A comprehensive market analysis on camera and illumination sensors for image processing and Machine Vision applications. International Conference on Computational Intelligence and communication Networks, p. 382–385.

[16] Wissanu Suwannawong. (2018). Applied Detection System for In-Out of Car Parking Nakhon Ratchasima Vocational College. In The 6th National and International Conference (CASNIC), p. 441–451.

[17] Chowdhury, A.I., Rahman, M.S. & Sakib, N. (2019) A Study on Multiple Barcode Detection from an Image in Business System. International Journal of Computer Applications (0975-8887), 181(37), 30-37.

[18] Rahman, M.S., Chowdhury, A.I. & Zawad, K.M. (2019). An Approach to Facilitate Business System by Multiple Barcode Detection using Faster RCNN. International Journal of Applied Information Systems (IJAIS), 12(26), 10-15.

[19] Fu, Y. & Wang, N. (2013). Measurement of dust concentration based on VBAI. 7th International Conference on Applied Electrostatics (ICAES-2012) Journal of Physics: Conference Series, 418(1), 1-7.

[20] Tomari, M.R., Lias, J., Musa, R. & Zakaria, W.N. (2015). DEVELOPMENT OF RED BLOOD CELL ANALYSIS SYSTEM USING NI VISION BUILDER AI. ARPN Journal of Engineering and Applied Sciences.

[21] Phanuwat Mek. (2015). Machine vision applications for automated inspection. Maejo University: General learning exchange articles. (Science and technology).

[22] Sekhar, V.G., Kumar, S.N., Fred, L. & Varghese S. (2016). An improved color segmentation algorithm for the analysis of liver anomalies in CT/PET images. IEEE International Conference on Engineering and Technology (ICETECH), p. 1151-1154.

[23] Anucha Tungkasathan. & Kasama Leewan. (2018). Pixel-Based Car Model Detection and Recognition. Eng. J. Siam Univ, 19(1), 90-102.

[24] Deaw Jaibun. (2011, October 14). Measures of Central Value. Mahidol Wittayanusorn School: Basic statistics, p. 17-18.

[25] Pornsap Pornsawat; (2013). Numerical analysis. 1st ed. Nakhon Pathom: Silpakorn University.

[26] Shnidman, D.A. (1989, March). The calculation of the probability of detection and the generalized Marcum Q-function. In IEEE Transactions on Information Theory, 35(2), 389-400.

[27] Sarkar, A., Chakraborty, S & Roy B.K. (2015) Image processing based product label quality control on FMCG products. International Conference on Energy, Power and Environment: Towards Sustainable Growth (ICEPE), p. 1-5.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2021 Engineering Access

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.