An Optimization of Moisture Losses and Drying Properties of Orange Peel Reinforcement for Composite Fabrication Using the Taguchi Method

doi: 10.14456/mijet.2022.12

Keywords:

Orange peels, Taguchi method, factor levels, method of means, percentage improvementAbstract

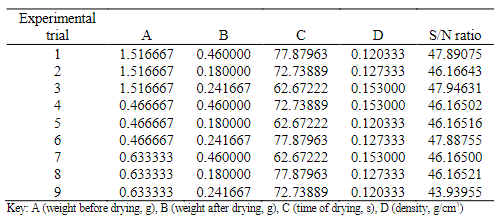

Moisture content evaluation is a primary method in the processing and testing of agro-based reinforcement during composite preparation since the moisture content of reinforcement is of direct economic significance to the composite developer. However, its optimization has been of interest to its stakeholders. Unfortunately, the classical Taguchi method which has been extensively applied in the composite industry still suffers some shortcomings, including its heavy reliance on the traditional mean method of averaging values during computations. This unfortunately leads to wrong information and deficiencies in decision making. To conquer these deficiencies, three new methods of averaging, namely, the geometric, harmonic and quadratic means have been proposed. Some evidence has been found that all three alternative means could replace the average method. The harmonic is the best for economic consideration. In addition, for the percentage improvement of optimal values of the parameters, the principal results confirmed that in scenarios 1 to 3, positive results were obtained except scenario 4 when the index comparing the current to the base method was evaluated. Important improvements in composite fabrications and design could be made with the information provided in this for research engineers.

References

G. Miranda, A. Berna, A. Bone, A. Mulet, "Modeling of the process of moisture loss during the storage of dried apricots, " Food Science and Technology International, vol.17, no. 5, 2011, pp. 439-447.

H. Kawagishi, A. Onoda, N. Shibukawa, Y Niizeki, "Development of moisture loss models in steam turbines," Heat Transfer, vol. 42, no. 7, 2013, pp.651-664.

A. R. Soleimani Pour-Damanab, A. Jafary and S. Rafiee, "Determination of suitable drying curve model for bread moisture loss during baking," International Agrophysics, vol.27, 2013, pp. 233-237, DOT: 102478/v/0247-012-0090-y.

F. Salehi, M. Kashaniejad, "Modeling of moisture loss kinetics and colour changes in the surface of lemon slice during the combined infrared vacuum drying," Information Processing in Agriculture, vol.5, no.4, 2018, pp.516-523.

M. Islam, K. A. Wahid, A. V. Dinh and P. Bhowmik, "Model of dehydration and assessment of moisture content on onion using EIS," Journal of Food Science and Technology vol.56, 2019, pp.28142824, Dot: 10.1007/s13197-019-03590-3.

J. A. Adeyanju, J. O. Olajide, E. O. Oke and A. A. Adedeji, "Modelling of moisture loss and oil uptake during deep-fat frying of plantain (dodo)," Arid Zone Journal of Engineering, Technology and Environment, vol. 14, 2020, pp. 51-61.

B. V. Kokta, R. G. Roy and C. Daneault, "Use of wood flour as filler in polypropylene: studies on mechanical properties," Polymer Plastic Technology, vol. 28, 1989 pp. 247-259.

M. M. Sain, J. Balatinecz, S. Law, "Creep Fatigue in Engineered Wood Fibres and Plastic Composites," Journal of Applied Polymer Science, vol. 77, no. 23, 2000, pp. 260-268.

M. Sain, S. Law, F. Suhara and A. Boullinox, "Stifness correlation of natural fibre filled polypropylene composites," Proceedings of Wood Fibre Polymer Composites Symposium, 2003, pp. 25-27.

S. Panthapulakkal and M. Sain, "Enhancement of processability of rice husk filled-high density polyethylene composite," Journal of Thermoplastic Composite Materials, vol. 18, no. 5, pp. 445-459, 2005.

M. S. Saleman and A. S. Luyt, "Thermal and Mechanical properties of Polypropylene-Wood Powder Composites," Journal of Applied Polymer Science, vol. 100, no. 67, pp. 4173-4180, 2006.

S. Ochi, "Mechanical properties of kenaf fiber and kenaf/pla composites," Mechanical Materials, vol. 40, 2008, pp. 446-452.

S.M.L. Rosa, S.M.B Nachtigall and C.A Ferreira, "Thermal and dynamic mechanic characteristics of rice husk filled polypropylene composites," Macromol. Res., vol. 17, no. 1, 2009, pp. 8-13.

B. Dimzoski, G. Bogoeva-Gacva, G. Gentile, M. Avella and A. Grozdanor, "Polypropylene-based eco-composites filled with agricultural rice husk waste," Chemical and Biochemical Engineering Quarterly, vol. 23, no. 2, 2009, pp. 225-230.

W. A. Rahman, T. S. Lee, A. R. Rahmatt, N. M. Isa, M. S. N. Salleh and M. Mokhtar M., "Comparison on rice husk filled poly ethylene composite and natural wood under weathering effects," Journal of Composite Materials, vol. 45, no. 13, 2011, pp. 1403-1411.

M. M. Kabir, H. Wang, K. T. Lau, F. Cardona and T. Aravinthan, "Mechanical properties of chemically-treated hemp fibre reinforced sandwich composites," Composites Part B: Engineering, vol. 43, 2011, pp. 159-169.

A. H. Abdullab, S. K. Alias, N. Jenaf, K. Abdan and A. Ah., "Fatigue behaviour of kenaf fibre reinforced epoxy composite," Engineering Journal, vol. 16, no. 5, 2012, pp. 105-113.

A. Getu and O. Sahu, "Green composite material from agricultural waste," International Journal of Agricultural Research and Review, vol. 2, no. 5, 2014, pp. 65-62.

J. D. Vera, R. F. Matthews, P. G. Crandall and R. Cook, "Preparation and chemical composition of orange oil concentrates," Journal of Food Science, vol. 48, no.4, 1983, pp. 1197 – 1197.

J. Pino, M. Sarchez, R. Sanchez and E. Rocal, "Chemical composition of orange oil concentrates," Nahrung/Food, vol. 36, no. 6, 2006, pp. 539-542.

S. Ojha, G. Regharendra, S. K. Acharya and P. Kumar, "Fabrication and study of mechanical properties of orange peel reinforced polymer composite," Caspain Journal of Applied Sciences Research, Vol. 1, No. 13, 2012, pp. 190-192.

S. T. Kumar, "Mechanical behaviour of orange peel reinforced epoxy composite, Unpublished B. Tech. Project," Department of Mechanical Engineering, National Institute of Technology, Rourkela, India, 2012.

V. S. Aigbodion, C. U. Atuanya, E. A. Igogori and P. Ihom, 2013, "Development of high-density polyethylene/orange peels particulate bio-composite," Gazi University Journal of Science, vol. 26, no. 1, 2013, pp. 107-117.

O. A. Ajibade, J. O. Agunsoye and S. A. Oke, "Analysis of the free-swell behaviour of orange peel particulates as reinforcement for green composite fabrication," Acta Periodica Technologica, vol. 46, 2015, pp. 131-147

O. A. Ajibade, J. O. Agunsoye and S. A. Oke, S.A. 2015, "Experimentation and prediction of moisture characteristics and density of sweet orange peels used for epoxy-based composite fabrication," Journal of The Association of Professional Engineers of Trinidad and Tobago, vol. 43, no. 2, October, 2015, pp. 44-52.

T. Y. Tunde-Akintunde, O. J. Oyelade and B. O. Akintunde, "Effect of drying temperatures and pre-treatments on drying characteristics, energy consumption, and quality of bell pepper," Agricultural Engineering International: CIGR Journal, vol. 16, no. 2, 2014, pp. 108-118.

A. O. Raji and S. A. Oke, "Optimization of EDM for AA6061/10%Al2O3 AMMC using Taguchi schemes and analytical hierarchy process for weight determination," Kufa Journal of Engineering, vol. 11, no. 3, 2020, pp. 42-61.

S. Nwafor, S. Oke and C. Ayanladun, "Taguchi optimisation of cast geometries for A356/organic particulate aluminium alloy composites using a two-phase casting process," Journal of Applied Science & Process Engineering, vol. 6, no. 2, 2019, pp. 386-411.

A. D. Polyanin and A. V. Manzhirov, "Handbook of Mathematics for Engineers and Scientists," Chapman & Hall/CRC, Boca raton, USA, 2007.

Downloads

Published

How to Cite

Issue

Section

License

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.