Optimal Asset Management of Distribution Transformers Considering Life Cycle Costs

doi: 10.14456/mijet.2021.20

Keywords:

Distribution transformer, Genetic algorithm, Maintenance and replacement schedule, Maintenance costs, Optimization modelAbstract

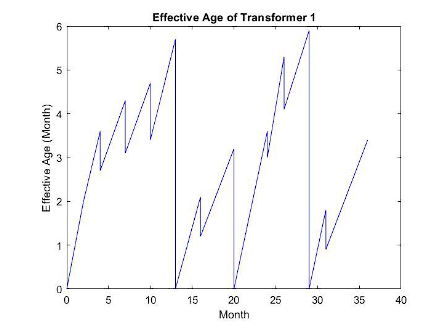

The optimal maintenance and replacement of distribution transformers can reduce the costs of maintenance and replacement and increase the transformer availability which can increase the system reliability as well. From the previous research works, they considered either maintenance or replacement of industrial equipment to determine the most appropriate scheme. Both maintenance and replacement of equipment have not been simultaneously considered before. Moreover, the asset value of the equipment has not been taken into account. Consequently, this paper presents the mathematical model of the optimal scheduling of transformer maintenance and replacement considering the asset value and the life cycle cost of the transformer. The purpose of the developed model is to minimize total cost while maintaining the defined level of transformer reliability. The considered costs compose of failure cost, maintenance and replacement costs. The Genetic Algorithm (GA) was applied to solve the optimization problem of the proposed model using MATLAB. The numeric results are presented as a graph for the system planner to decide for replacing and maintaining the transformer based on the life cycle cost of the transformer. The results from the proposed mathematical model can reduce the total cost by 36 % compared with the total cost before using the optimal schedule.

References

[2] Rommert D. (1996) Applications of maintenance optimization models: a review and analysis. Reliability Engineering and System Safety, Elsevier Science Limited Printed in Northern Ireland, pp 229-240.

[3] Wang H. Z., and Pham, H., (2006) Reliability and Optimal Maintenance, Springer, 2006.

[4] Ho-Joon S., (2008) Optimal Maintenance of a Multi-Unit System Under Dependencies, School of Aerospace Engineering, Georgia Institute of Technology, December 2008, pp 7-29.

[5] Abdullah A. A., Peter D. B., and Ashutosh T., (2013) Applications of simulation in maintenance research; World Journal of Modelling and Simulation, Vol. 9 (2013) No. 1, pp. 14-37.

[6] Yao, X, Fernandez-Gaucherand, E., Fu, M.C., and Marcus, S.I., (2004) Optimal preventive maintenance scheduling in semiconductor manufacturing, IEEE Transactions on Semiconductor Manufacturing, v 17, n 3, August 2004, p 345-356.

[7] Han, B.J., Fan, X.M., and Ma, D.Z., (2004) Optimization of preventive maintenance policy of manufacturing equipment based on simulation, Computer Integrated Manufacturing Systems, v 10, n 7, July 2004, p 853-857.

[8] Zhao, Y., Volovoi, V, Waters, M., and Mavris, D., (2005) A sequential approach for gas turbine power plant preventive maintenance scheduling, 2005 ASME Power Conference, 5-7

April 2005, Chicago, IL, USA, p 353-362.

[9] Canto, S.V., (2006) Application of Benders' decomposition to power plant preventive maintenance scheduling, European Journal of Operational Research, v 184, Issue 2, January 2006, p 759-777.

[10] Budai, G., Huisman, D., and Dekker, R., (2006) Scheduling preventive railway maintenance activities, Journal of the Operational Research Society, v 57, n 9, September 2006, p 1035-44.

[11] Kuo, Y., and Chang, Z.A., (2007) Integrated production scheduling and preventive maintenance planning for a single machine under a cumulative damage failure process, Naval Research Logistics, v 54, n 6, September 2007, p 602-614.

[12] Cavory, G., Dupas, R., and Goncalves, G., (2001) A genetic approach to the scheduling of preventive maintenance tasks on a single product manufacturing production line, International Journal of Production Economics, v 74, n 1-3, December 2001, p 135-46.

[13] Bris, R., Chatelet, E., and Yalaoui, F., (2003) New method to minimize the preventive maintenance cost of series-parallel systems, Reliability Engineering and System Safety, v 82, n 3, December 2003, p 247-55

[14] Limbourg, P., andKochs, H.D., (2006) Preventive maintenance scheduling by variable dimension evolutionary algorithms, International Journal of Pressure Vessels and Piping, v 83, n 4, April 2006, p 262-269

[15] Tan, J.S., and Kramer, M.A, (1997) A general framework for preventive maintenance optimization in chemical process operations, Computers and Chemical Engineering, v 21, n 12, 1997, p 1451 1469.

[16] Shalaby, M.A., Gomaa, AH., and Mohib, AM., (2004) A genetic algorithm for preventive maintenance scheduling in a multiunit multistate system, Journal of Engineering and Applied Science, v 51, n 4, August 2004, p 795- 811.

[17] Samrout, M., Yalaoui, F., Chatelet, E., Chebbo, N., (2005) New methods to minimize the preventive maintenance cost of series-parallel systems using ant colony optimization, Reliability Engineering and System Safety, v 89, n 3, September 2005, p 346-354.

[18] J. Holland. Adoption in natural and artificial systems. The MIT press, 1975, 211.

[19] M. Mitchell. An introduction to genetic algorithms. The MIT Press, 1996, 208.

[20] N.R. Harvey, S. Marshall. The design of different classes of morphological filter using genetic algorithms. IEE fifth international conference on image processing and its applications, 1995, 227 – 231.

[21] P. W. M. Tsang, A.T.S. Au. A genetic algorithm for projective invariant object recognition. Conference proceedings, 1996 IEEE TENCON: Digital Signal Processing Applications, 1996, 58 – 63

[22] S.E. Papadakis, P. Tzionas, V.G. Kaburlasos, J.B. Theocharis. A genetic based approach to the type I structure identification. Informatica, 2005, Vol.16, No. 3, 365 – 382.

[23] A. Misevicius. Experiments with hybrid genetic algorithm for the grey pattern problem. Informatica, 2005, Vol.17, No.2, 237 – 258.

[24] H.P Schwefel, G. Rudolph. Contemporary evolution strategies. Advances in artificial life, 1995, 893 – 907

[25] Gembicki, F.W., (1974) Vector Optimization for Control with Performance and Parameter Sensitivity Indices, Ph.D. Thesis, Case Western Reserve University., Cleveland, Ohio, USA.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2021 Engineering Access

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.