The Effects of Para Rubber Latex on Compressive Strength, Elastic Modulus, and Water Permeability of High Strength Concrete

doi: 10.14456/mijet.2022.4

Keywords:

High strength concrete, Para rubber latex, Compressive strength, Elastic modulus, Water permeabilityAbstract

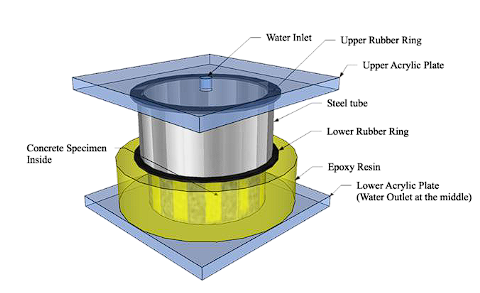

The objectives of this research were to study of compressive strength, elastic modulus and water permeability of high strength concrete containing low ammonia concentrated latex. The designed strength of concrete samples was 45 MPa. Some amounts of water in concrete mixtures were replaced by the concentrated latex at the percentage of 0.5, 1.0, 1.5, and 2.0 by weight. Each mixture was tested for slump, compressive strength, elasticity modulus, and water permeability. The compressive strength and elasticity modulus were observed by using concrete samples, having 10 cm in diameter and 20 cm in height at the ages of 3, 7, 14, and, 28 days of curing. The required slump was between 7.5 cm and 12.5 cm. The result showed that the increasing of concentrated latex decreased slump of the fresh concrete. The 28-day compressive strengths of the latex concretes containing 0.5, 1.0, and 1.5% of latex replacement showed a little higher than the control concrete’s while the 2.0% replacement was dramatically lower. The elastic modulus varied directly to compressive strength of all mixtures. At the same time, almost all mixtures of latex concrete obviously provided lower water permeability than the control one, especially the 1.5% replacement which was about 3 times lower. Thusly, a proper amount of the concentrate latex could be used well in high strength concrete work for increasing its impervious aspect.

References

[2] P. Sharvin, R. M. H. Mohd, and P. J. Ramadhansyah, “Impacts of recycled crumb rubber powder and natural rubber latex on the modified asphalt rheological behavior, bonding, and resistance to shear”, Construction and Building Materials, vol. 234, pp. -, 2020.

[3] J. Wongpa, and P. Thongsanitgarn, “Effect of para rubber latex and coir on compressive strength, water absorption and volumetric change of adobe brick”, International Journal of Agricultural Technology, vol. 14(7), pp. 2229-2240, 2018.

[4] J. Wongpa, S. Koslanant, W. Chalee, and P. Thongsanitgarn, “Effects of para rubber latex on workability, compressive strength and water permeability of normal strength concrete”, Mahasarakham International Journal of Engineering, vol. 7(1), pp.61-66, 2021.

[5] A. Moreno Bazán, J. Galvez, E. Reyes, and G. L. Lamuela, “Study of the rust penetration and circumferential stresses in reinforced concrete at early stages of an accelerated corrosion test by means of combined SEM, EDS and strain gauges”, Construction and Building Materials, vol. 184, pp. 655-667, 2018.

[6] P. Cady and R. Weyers, “Chloride penetration and the deterioration of concrete bridge decks”, Cement, Concrete and Aggregates, vol. 5(2), pp. 81-87, 1983.

[7] ASTM International. ASTM C143 / C143M-20: Standard Test Method for Slump of Hydraulic-Cement Concrete. ASTM International, 2020.

[8] ASTM International. ASTM C150 / C150M-20: Standard Specification for Portland Cement. ASTM International, 2020.

[9] ACI Committee 211. Standard Practice for Selecting Proportions for Normal, Heavyweight, and Mass Concrete (ACI 211.1-91) Reapproved 2002. American Concrete Institute, 2020.

[10] ASTM International. ASTM C192 / C192M-19: Standard Practice for Making and Curing Concrete Test Specimens in the Laboratory. ASTM International, 2019.

[11] ASTM International. ASTM C39 / C39M-21: Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. ASTM International. 2021.

[12] W. Sanawung, T. Cheewaket, W. Tangchirapat, and C. Jaturapitakkul, “Influence of palm oil fuel ash and W/B ratios on compressive strength, water permeability, and chloride resistance of concrete”, Advances in Materials Science and Engineering, vol. -, pp. -, 2017.

[13] N. Kakhuntodd, P. Chindaprasirt, C. Jaturapitakkul, and S. Homwuttiwong, “The investigation of water permeability of high volume pozzolan concrete”, Journal of Science and Technology Mahasarakham University, vol. 31(5), pp. 563-570, 2012.

[14] J. Wongpa, K. Kiattikomol, C. Jaturapitakkul, and P. Chindaprasirt, “Compressive strength, modulus of elasticity, and water permeability of inorganic polymer concrete”, Materials and Design, vol. 31, pp. 4748-4754, 2010.

[15] J. Bu, and Z. H. Tian, “Relationship between pore structure and compressive strength of concrete: Experiments and statistical modeling”, Sãdhanã, vol. 14(3), pp. 337-344, 2016.

[16] ACI Committee 318. Building Code Requirements for Structural Concrete (ACI 318-95) and Commentary (ACI 318R-95). American Concrete Institute, 1995.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2021 Engineering Access

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.