Improvement Biogas Generating by the Fermenting Barrel for Biogas Production from Organic Waste for Household Use

doi: 10.14456/mijet.2022.5

Keywords:

biogas fermenting barrel, biogas, molasses, glycerin, pig manureAbstract

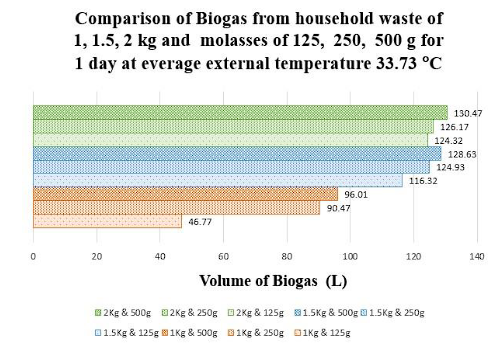

This study was aimed to increase biogas generating from organic waste in the 120-liter fermenting barrel for household use by adding effective nutrients of molasses and glycerin. In the experiment, volumes of the organic waste were 1, 1.5 and 2 kilogram whereas the molasses and glycerin were added at 125, 250 and 500 grams respectively. The results revealed that the biogas volume from organic waste added with 500-gram molasses was averagely 1.17 and 1.46 times greater than those added with 250-gram and 125-gram molasses respectively. Likewise, the biogas volume from organic waste added with 500-gram glycerin was averagely 1.03 and 1.31 times greater than those added with 250-gram and 125-gram glycerin respectively. In conclusion, the biogas volume depends on the nutrient added volume and external temperature. The economic feasibility of the barrel for biogas production from organic waste was analyzed using the payback period (PB). The analysis results show that the barrel for biogas production from organic waste is economically feasible payback period =1 year and 3 months.

References

[2] Bouallagui, H., Ben Cheikh, R., Marouani, L., & Hamdi, M. (2003). Mesophilic biogas production from fruit and vegetable waste in a tubular digester. Bioresource Technology, 86(1), 85-89.Ashis Paul [Online]. Available at: https://observers.france24.com/en/20160602-bangladesh-air-conditioner-plastic-bottles-technology.

[3] Elmitwalli, T. A., Oahn, K. L. T., Zeeman, G., & Lettinga, G. (2002). Treatment of domestic sewage in a two-step anaerobic filter/anaerobic hybrid system at low temperature. Water Research, 36(9), 2225-2232.

[4] P. Suksutharat,S. Chobbun, N. Witjitsomboon and A. Dechana (2011). Development of biogas tank from organic waste. Songkhla: Faculty Science and Technology, Songkhla Rajabhat University Science center Songkhla Rajabhat University.

[5] S. Limsuk (2011). Biogas production from food scraps with crude glycerin obtained from biodiesel production. KKU Engineering Journal, 38 (2), 101-110.

[6] Callaghan, F. J., Wase, D. A. J., Thayanithy, K. and Forster, C. F., (2007). Continuous codigestion of cattle slurry with fruit and vegetable wastes and chicken manure Biomass and Bioenergy, Vol. 27, p.71

[7] El Mashed, H. M., and Zhang, R.(2010). Biogas production from codigestion of daily manure and food waste Bioresource Technology, Vol. 101, p4021.

[8] Zheng, C., Su, H. and Baeyens, T. T. (2014). Reviewing the anaerobic digestion of food waste for biogas production. Renewable Sustain Energy Review, 38: 383-392.

[9] Angelidaki, I., Alves, M., Bolzonella, D., Borzacconi, L., Campos,

J.L., Guwy, A.J., Kalyuzhnyi, S., Jenicek, P., van Lier, J.B. 2009.

Defining the biomethane potential (BMP) of solid organic wastes

and energy crops: a proposed protocol for batch assays. Water

Science and Technology, 59(5), 927-934.

[10] Gerardi, M.H. (2003). The Microbiology of Anaerobic Digesters. John Wiley & Sons, Inc., Hoboken.

[11] Kondusamy, D. and Kalamdhad, A.S. 2014. Pre-treatment and anaerobic digestion of food waste for high rate methane production-A review. Journal of Environmental Chemical Engineering, 2:1821-1830.

[12] Karim, K., Hoffman, R., Thomas Klasson, K. and Al-Dahhan, M.H. 2005. Anaerobic digestion of animal waste : Effect of mode of mixing. Water Research, 39(15): 3597-3606.

[13] S. Moonsrikaew, D. Chittathanaseshthม N. Khajornchaikul, A. Phumivithcha and S., Bunyoung 2012. The Comparative Performance of Biogas from Animal Manure in the small plastic tanks and plastic bags to use as houshold fuel. Research report, fiscal year 2011. University Rajamangala University of Technology Suvarnabhumi. 14 p.

[14] Amon, Th., Amon, B., Kryvoruchko, V., Bodiroza, V., Potsch, E., and Zollitsch, W., (2006). Optimising methane yield from anaerobic digestion of manure: Effects of dairy systems and of glycerine supplementation International Congress Series 1293, p.217-220.

[15] Marañón, E., Castrillón, L., Quiroga, G., Fernández-Nava, Y., Gómez and García, M.M. 2012. Codigestion of cattle manure with food waste and sludge to increase biogas production. Waste Management, 32: 1821-1825.

[16] Nagao, N., Tajima, N., Kawai, M., Niwa, C., Kurosawa, N., Matsuyama, T., Yusoff, F. Md. And Toda, T. 2012. Maximum organic loading rate for the single-stage wet anaerobic digestion of food waste. Bioresource Technology, 188: 210-218.

[17] Agyeman, F.O. and Tao, W. 2014. Anaerobic co-digestion of food waste and dairy manure:Effects of food waste particle size and organic loading rate. Journal of Environmental Management, 133: 268-274.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2021 Engineering Access

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.