Aspect Ratio Consideration in the Optimisation of Maintenance Downtime for Handling Equipment in a Container Terminal

doi: 10.14456/mijet.2022.18

Keywords:

Container ports handling equipment, downtime, optimality, process parametersAbstract

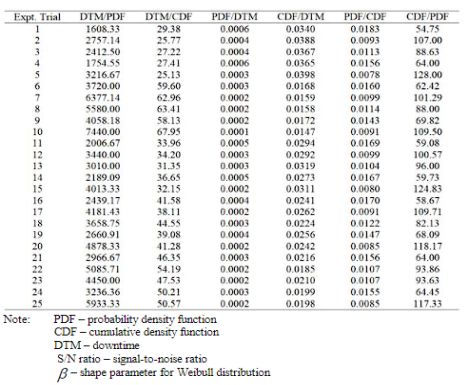

The idea of downtime optimisation is an effective means of minimizing losses of handling equipment in the container port terminal. Unfortunately, previous research relies on the direct factors of downtime, namely downtime parameter (DTM), probability density function (PDF), cumulative density function (CDF) but fails to use the aspect ratios of parameters to more effectively control downtime using the Taguchi method. This gap has resulted in the wrong results and decision making. To correct this problem, this article proposes six aspect ratio parameters to replace existing parameters, namely DTM/PDF, DTM/CDF, PDF/CDF, PDF/DTM, CDF/DTM, and CDF/PDF. These factors were used to obtain the signal-to-noise ratios, the response table and the optimal parametric settings for each Weibull distribution function parameter of β=0.5, 1 and 3. It was found that the outcome at β=3 had the best values and should be used for decision making. For instance, at β=1, DTM/PDF of 92.56 hrs <DTM/PDF of 1222.33 hrs at β=3 <DTM/PDF of 1706.50 hrs at β=0.5. Consequently, the optimal parametric setting at β=1 is DTM/PDF1 DTM/CDF1 PDF/DTM5 CDF/DTM4 PDF/CDF3 CDF/PDF2. This is interpreted as 92.52 hrs of DTM/PDF, 24.87 hrs of DTM/CDF, 0.0063 hr-1 of PDF/DTM, 0.267 hr-1 of CDF/DTM, 0.2897 hr-1 of CDF/DTM, 0.2897 of PDF/CDF and 3.68 of CDF/PDF. The novelty of this article is the use of aspect ratios of the parameter to effect maintenance optimisation. The presented approach aids the ports engineer in the proper planning and control of ports activities.

References

A.S.M. Shahjahan, “Cargo Handling Equipment Productivity Analysis of the Chittagong Port Authority,” World Maritime University, M.Sc dissertation, 2000.

K.A. Kim, M.-H.T. Phan, Y.J. Woo, “New Conceptual Handling Systems in Container Terminal,” Industrial Engineering and Management Systems, vol. 11, no. 4, pp. 299-309, 2012, doi:10.7232/iems.2012.114.299.

G.A.A. Said, E.M. El-Horbaty, An Optimisation Methodology for Container Handling using Genetic Algorithm, Procedia Computer Science, vol.65, pp.662-671, 2015. doi:10.1016/jprocs. 2015.09.010.

M. Kastner, N. Kammerling, C. Jahn, U. Clausen, “Equipment Selection and Layout Planning. Literature Overview and Research Directions,” in Jahn C.K., Ringle W., Christian M., (Ed): Data Science in Maritime and City Logistics: Data-driven Solutions for Logistics and Sustainability, Proceedings of the Hamburg International Conference of Logistics, Berlin, vol. 30, pp. 485-519, 2020.doi:10.15480/882.3147.

L. Okanminiwei, S.A. Oke, “Optimisation of Maintenance Downtime for Handling Equipment in a Container Terminal Using Taguchi Scheme, Taguchi-Pareto Method and Taguchi-ABC Method,” Indonesian Journal of Industrial Engineering & Management, vol. 1, no. 2, pp. 69-90, 2020. DOI: 10.22441/ijiem.v1i2.9912

L. Song and M. van Geehuizen, “Port Infrastructure Investment and Regional Economic Growth in China: Panel Evidence in Port Regions and Provinces,” Transport Policy, vol 36, pp. 173-183, 2014.

B.A. Priyambodho, “Container Port Development Projects on the Java Sea, Indonesia, Jurnal Fondasi, vol. 5, no.1, pp. 36-45, 2016.

C.A. Buchanan, M. Charara, J.L. Sullivan, G.M. Lewis, G.A. Keoleian, “Lightweighting Shipping Containers: Life Cycle Impacts on Multimodal Freight Transportation,” Transportation Research Part D: Transport and Environment, vol. 62, pp. 418-432, 2018. https://doi.org/10.1016/j.trd.2018.03.011.

F. Suprata, C. Natalia, A. Sugioko, “Analysing the Cause of Idle Time in Loading and Unloading Operation at Indonesian International Port Container Terminal: Port of Tanjung Priok Case Study, May 2020, Conference: 12th ISIEM (International Seminar On Industrial Engineering & Management): "Industrial Intelligence System On Engineering, Information, and Management" 17-19 March 2020, Batu, Malang - East Java, Indonesia At: Indonesia, IOP Conference Series Materials Science and Engineering 847. DOI: 10.1088/1757-899X/847/1/012090

H. Hussin and F.M. Hashim, 2011, Modeling of Maintenance Downtime Distribution Using Expert Opinion, Journal of Applied Sciences, vol. 11, pp. 1573-1579. doi: 10.3923/jas.2011.1573.1579

H. Ujiie, Y. Tamano, K. Sasaki, T. Hori, “Is the Aspect Ratio a Reliable Index for Predicting the Rupture of a Saccular Aneurysm?” Neurosurgery, vol. 48, no. 3, pp. 495-503, 2001. DOI: 10.1097/00006123-200103000-00007

Lim T.C., “Aspect Ratio and Size Effects of a Metacomposite with Interconnected Y-Elements,” Journal of Physics: Conference Series, vol. 2047, the 4th International Conference on Material Strength and Applied Mechanics, 16-19 August 2021, Macau, China.

S. Cardwell, “A Sense of Proportion: Aspect Ratio and the Framing of Television Space, Critical Studies in Television: The International Journal of Television Studies, vol. 10, no., 3 pp. 83-100, 2015.

A. Celzard, E. McRae, C. Deleuze, M. Dufort, G. Furdin and J.F. Mareche, “Critical Concentration in Percolating Systems Containing a High-Aspect-Ratio Filler, Physical Review B, vol. 53, no. 10, pp. 6209-6214, 1996.

A.O. Raji and S.A. Oke, “Enhancement of Maintenance Downtime Using Poisson Motivated-Taguchi Optimisation Method,” Al-Nahrain Journal for Engineering Sciences, vol. 22, no. 4, pp. 294-306, 2019.

J.A. Fadeyi, M.O. Okwu, C.O. Mgbemena, K.C. Ezekiel, “The Pareto Principle and a Hazard Model as Tools for Appropriate Scheduled Maintenance in a Manufacturing Firm, African Journal of Science, Technology, Innovation and Development, vol. 8, no. 2, pp. 173-177, 2016. https://doi.org/10.1080/20421338.2016.1147203

S.C. Nwanya, J.I. Udofia & O.O. Ajayi, Optimization of Machine Downtime in the Plastic Manufacturing, Cogent Engineering, Vol. 4, No. 1, 2017, Article: 1335444. https://doi.org/10.1080/23311916.2017.1335444

R. Zheng, C. Su, Y. Zheng, “Two-Stage Flexible Warranty Decision-Making Considering Downtime Loss,” Proceedings of the Institution of Mechanical Engineers, Part O: Journal of Risk and Reliability, vol.234, no. 3, pp. 527-535, 2020. https://doi.org/10.1177/1748006X19889261

J.M. Wakiru, L. Pintelon, P. Muchiri, P. Chemweno, “Integrated Maintenance Policies for Performance Improvement of a Multi-Unit Repairable, One Product Manufacturing System,” Production Planning & Control, vol. 32, no. 5, pp. 347-367, 2021.

https://doi.org/10.1080/09537287.2020.1736684

S.T. Huang, E. Bulut, O. Duru, “Multi-Dimensional Service Improvement Under the Multi-Customer Nature of Container Terminals,” International Journal of Shipping and Transport Logistics, vol. 8, no. 2, pp. 194-222, 2016. doi: 10.1504/IJSTL.2016.075011

T. Schellinck, M.R. Brooks, “Does Superior Service Performance Provided to Shipping Lines Improve the Perceived Value of a Port?” International Journal of Shipping and Transport Logistics, vol. 8, no.2, pp. 175-193, 2016. doi: 10.1504/IJSTL.2016.075009

H. Schøyen, J. Odeck, “Comparing the Productivity of Norwegian and Some Nordic and UK Container Ports - An Application of Malmquist Productivity Index,” International Journal of Shipping and Transport Logistics, vol. 9, no.2, pp.234 – 256, 2017. doi: 10.1504/IJSTL.2017.082526

J. Szpytko, Y.S. Duarte, “Digital Twins Model for Cranes Operating in Container Terminal,” IFAC-PapersOnLine, vol. 52, no. 10, pp. 25-30, 2019. https://doi.org/10.1016/j.ifacol.2019.10.014

G. Vrakas, C. Chan, V.V. Thai, “The Effects of Evolving Port Technology and Process Optimisation on Operational Performance: The Case Study of an Australian Container Terminal Operator,” The Asian Journal of Shipping and Logistics, In Press, 2021.

https://doi.org/10.1016/j.ajsl.2020.04.001

Z. Wan, T. Zhang, M. Sha, W. Guo, Y. Jin, J. Guo, Y. Liu, “Evaluation of Emission Reduction Strategies for Berthing Containerships: a Case Study of the Shekou Container Terminal,” Journal of Cleaner Production, vol. 299, Article 126820, 2021. https://doi.org/10.1016/j.jclepro.2021.126820

H.H. Turan, M. Atmis, F. Kosanoglu, S. Elsawah, M.J. Ryan, “A Risk-Averse Simulation-Based Approach for a Joint Optimization of Workforce Capacity, Spare Part Stocks and Scheduling Priorities in Maintenance Planning,” Reliability Engineering & System Safety, vol. 204, Article 107199, 2020. https://doi.org/10.1016/j.ress.2020.107199

R. Mena, P. Viveros, E. Zio, S. Campos, “An Optimization Framework for Opportunistic Planning of Preventive Maintenance Activities,” Reliability Engineering & System Safety, vol. 215, Article 107801, 2021. https://doi.org/10.1016/j.ress.2021.107801

A. Allal, M. Sahnoun, R. Adjoudj, S.M. Benslimane, M. Mazar, “Multi-Agent Based Simulation-Optimization of Maintenance Routing in Offshore Wind Farms,” Computers & Industrial Engineering, vol. 157, Article 107342, 2021. https://doi.org/10.1016/j.cie.2021.107342

J. Gao, J.J. Chen, B.X. Qi, Y.L. Zhao, K. Peng, X.H. Zhang, “A Cost-Effective Two-Stage Optimization Model for Microgrid Planning and Scheduling with Compressed Air Energy Storage and Preventive Maintenance,” International Journal of Electrical Power & Energy Systems, vol. 125, Article 106547, 2021. https://doi.org/10.1016/j.ijepes.2020.106547

B.F.P.A. Marfinov, A.J. Pratama, “Overall Equipment Effectiveness (OEE) Analysis to Minimize Six Big Losses in Continuous Blanking Machine,” Indonesian Journal of Industrial Engineering & Management, vol 1, no 1, pp. 25-32, 2020. doi: http://dx.doi.org/10.22441/ijiem.v1i1.8037

D.E. Ighravwe and S.A. Oke, “Applying Fuzzy Multi-Criteria Decision-Making Framework in Evaluating Maintenance Systems with an Emphasis on Human Tasks and Errors,” Mahasarakham International Journal of Engineering Technology, vol. 7, no. 1, pp. 67-77, 2021.

D.E. Ighravwe and S.A. Oke, “Selection of Outsourcing Relationship for a Maintenance System Using Fuzzy Axiomatic Design Principles and Fuzzy VIKOR,” Engineering Access, vol. 8, no. 1, pp. 1-14, 2022a.

D.E. Ighravwe and S.A. Oke, “A Green Preventive Maintenance Model Incorporating the Green Fuzzy Deployment Method with the WASPAS Approach for Production Lines,” Engineering Access, vol. 8, no. 1, pp. 22-30, 2022b.

Y. Rashed, H. Meersman, C. Sys, E. van de Voorde, T. Vanelslander, “A Combined Approach to Forecast Container Throughput Demand: Scenarios for the Hamburg-Le Havre Range of Ports,” Transportation Research Part A: Policy and Practice, vol. 117, pp. 127-141, 2018. https://doi.org/10.1016/j.tra.2018.08.010

K.L. Rødseth, P.B. Wangsness, H. Schøyen, “How Do Economies of Density in Container Handling Operations Affect Ships’ Time and Emissions in Port? Evidence from Norwegian Container Terminals,” Transportation Research Part D: Transport and Environment, vol. 59, pp. 385-399, 2018. https://doi.org/10.1016/j.trd.2017.12.015

T.G.Z. Moura, L. Garcia-Alonso, I. Rosal, “Influence of the Geographical Pattern of Foreign Trade on the Inland Distribution of Maritime Traffic,” Journal of Transport Geography, Vol. 72, pp. 191-200, 2018. https://doi.org/10.1016/j.jtrangeo.2018.09.008

K.C. Iyer, V.P.S.N. Nanyam, “Technical Efficiency Analysis Of Container Terminals In India,” The Asian Journal of Shipping and Logistics, vol. 37, no. 1, pp. 61-72, 2021. https://doi.org/10.1016/j.ajsl.2020.07.002

A. Nadi, S. Sharma, M. Snelder, T. Bakri, H. Lint, L. Tavasszy, “Short-Term Prediction of Outbound Truck Traffic from the Exchange of Information in Logistics Hubs: A Case Study for the Port of Rotterdam,” Transportation Research Part C: Emerging Technologies, vol. 127, Article 103111, 2021. https://doi.org/10.1016/j.trc.2021.103111

F.S. Mustafa, R.U. Khan, T. Mustafa, Technical Efficiency Comparison of Container Ports in Asian and Middle East Region Using DEA, The Asian Journal of Shipping and Logistics, vol. 37, no. 1, pp. 12-19, 2021. https://doi.org/10.1016/j.ajsl.2020.04.004

E.Y. Wong, K.K. Ling, X. Zhang, “Yield and Port Performance Shipping Allocation Model for Revamp Service Deployments Under a Dynamic Trading Landscape,” Transportation Research Part C: Emerging Technologies, vol. 130, Article 103279, 2021. https://doi.org/10.1016/j.trc.2021.103279

S.-Y. Kuo, P.-C. Lin, “Determinants of Green Performance in Container Terminal Operations: A Lean Management, Journal of Cleaner Production, vol. 275, Article 123105, 2020. https://doi.org/10.1016/j.jclepro.2020.123105

D. Pachakis and A.S. Kiremidjian, “Estimation of Downtime Related Revenue Losses in Maritime Ports Due to Earthquakes,” Report No. 146, Department of Civil and Environmental Engineering, Stanford University, pp. v-vi, 2005

N.S. Mohseni, “Developing a Tool for Designing a Container Terminal Yard,” Master Thesis, Delft University of Technology, 2011.

J. Rezarei, L. van Wullfften Pathe, L. Tavasszy, B. Wiegmans, F. Van der Laan, “Port Performance Measurement in the Context of Port Choice: An MCDA Approach,” Management Decision, vol. 57, no. 2, pp. 396-417, 2019. doi:10.1108/MD-04-2018-0482.

Downloads

Published

How to Cite

Issue

Section

License

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.