Evaluation of Optimal Wire Electrical Discharge Machining Parametric Scenarios of AZ91 Magnesium Alloy Based on AHP-Taguchi Analyses-Genetic Algorithms

doi: 10.14456/mijet.2023.15

Keywords:

Optimisation, electrical discharge machining, prioritization, global optimisationAbstract

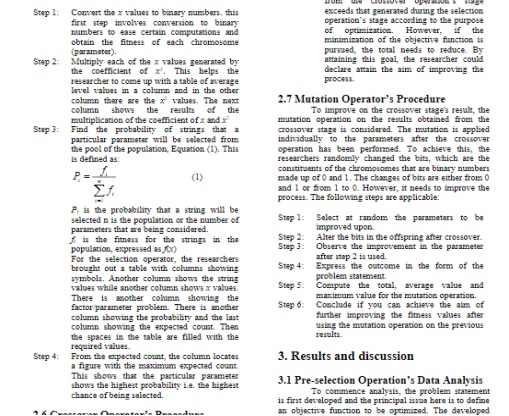

In this article, three robust parametric optimization schemes for the electrical discharge machining of AZ91 magnesium alloy are proposed using a hybrid analytic hierarchy process, Taguchi schemes and a genetic algorithm. The three methods are the AHP-T-GA (analytical hierarchy process-Taguchi method-genetic algorithm approach), AHP-TP-GA and AHP-TAPC-GA, where TP and TABC are Taguchi-Pareto and Taguchi-ABC methods, respectively. The methods were used as the cornerstone approaches to evaluate the parameters and classify them according to their importance. The parameters are namely the pulse on time, pulse off time, pulse current, gap voltage, wire feed and wire tension. The coupled models of AHP-T, AHP-TP and AHP-TABC already exist in the literature. However, the genetic algorithm is coupled with each of these methods to moderate the adverse economic and decision outcomes. Although the coupling of the Taguchi, Taguchi-Pareto and Taguchi-ABC method to AHP reduces errors, the provision of less information in a large-scale decision variable problem may lead to wrong decision making. However, introducing a mechanism capable of producing a large set of solution space, and multiple optimal and global solutions may moderate the tendency to make wrong decisions. The introduction of a genetic algorithm having these preceding features differentiates the three methods proposed in this article from previous research. Results suggest that the proposed robust methods have helped to improve the parametric performance of the wire EDM process and yielded higher values in a maximization scheme pursued in this article. However, the pulse current exhibited the highest value in the analysis. The results adequately represented the parametric scores obtained from ranks of parameters using data from the literature.

References

D. D. Trung, “The combination of Taguchi-entropy-WASPAS-PIV methods for multicriteria decision making when external cylindrical grinding of 65G steel,” Journal of Machine Engineering, vol. 21, no. 4, pp. 90-105, 2021.

R. Thirumalai, M. Seenivasan, K. Pannerselvam, “Experimental investigation and multiresponse optimization of turning process parameters of Inconel 718 using TOPSIS approach,” Materials Today: Proceedings, vol. 45, no. 2, pp. 467-472, 2021.

K. O. Okponyia, S. A. Oke, “Novel EDAS-Taguchi and EDAS-Taguchi-Pareto methods for wire EDM process parametric selection of Ni55.8Ti (nitinol) shape memory alloy,” International Journal of Industrial Engineering and Engineering Management, vol. 3, no. 2, pp. 105-122, 2021.

G. Singh, A. Kumar, V. Aggarwal, S. Singh “Experimental investigations and optimization of machining performance during turning of EN-31 steel using TOPSIS approach,” Materials Today: Proceedings, vol. 48, no.5, pp. 1089-1094, 2022.

S. L. Kumar, M. Subburaj, A. Kulandaivel, P. M. Kumar, A. Thanikasalam, R. Kumar “Multiple response optimization of machining parameters in turning nimonic C263 using TOPSIS approach,” vol. 59, no. 2, pp. 1414-1419, 2022.

S. Kumar, M. Gupta, P.S. Satsangi “Multi-response optimization of cutting forces in turning of UD-GFRP composite using distance-based Pareto genetic algorithm approach,” Engineering Science and Technology: An International Journal, vol. 18, no. 4, pp. 680-695, 2015.

R. Mukherjee, S. Chakraborty, S. Samanta “Selection of wire electrical discharge machining process parameters using non-traditional optimization algorithms,” Applied Soft Computing, vol. 12, no. 8, pp. 2506-2516, 2021.

R. Rajesh, M.D, Anand, “The optimization of the electrical discharge machining using response surface methodology and genetic algorithms,” Procedia Engineering, vol.38, pp. 3941-3950, 2012.

A. M. Ubaid, F. T. Dweiri, S. H. Aghdeab, L. A. Al-Juboori, “Optimization of electro discharge machining process parameters with fuzzy logic for stainless steel 304 (ASTM A240),” Journal of Manufacturing Science and Engineering, vol.140, no. 1, 011013, pp.1-13, 2018.

G. K. M. Rao, G. Rangajanardhaa, D. H. Rao, M. S. Rao, “Development of hybrid model and optimization of surface roughness in electric discharge machining using artificial neural networks and genetic algorithm,” Journal of Materials Processing Technology, vol. 209, no. 3, pp. 1512-1520, 2009.

M. A. Moghaddam, F. Kolahan, “Modeling and optimization of surface roughness of AISI2312 hot worked steel in EDM based n mathematical modelling and genetic algorithm,” International Journal of Engineering Transactions C: Aspects, Vol. 27, No. 3, pp. 417-424, 2014.

O. P. Francis, S. A. Oke, U. S. Nwankiti, “Application of Taguchi, Taguchi-Pareto and Taguchi-ABC methods for the selection and optimization problem of AA6062-T6 alloy,” Engineering Access, vol. 8, no. 2, pp. 267-280, 2022.

R. M. Adegoke, S. A. Oke, U. S. Nwankiti, “Analysing the effect of aspect ratios on optimal parametric settings using Taguchi, Taguchi-Pareto and Taguchi-ABC method. A case study in turning operations for the Inconel X750 alloy,” International Journal of Industrial Engineering and Engineering Management, vol. 4, no. 1, pp. 27-36, 2022

L. Okanminiwei, S. A. Oke, “Optimization of maintenance downtime for handling equipment in a container terminal using Taguchi scheme, Taguchi-Pareto and Taguchi-ABC method,” Indonesian Journal of Industrial Engineering and Management, vol. 1, no. 2, pp. 69-90, 2020.

E. O. Taiwo, S. A. Oke, “Optimizing to minimize thrust force in drilling carbon force reinforced plastic composites with HSS drill bit using Taguchi-Pareto-particle swarm optimization method,” International Journal of Industrial Engineering and Engineering Management, vol. 4, no. 1, pp. 37-48, 2022.

O. J. Abayomi, S. A. Oke, “Optimization of process parameters for a wind turbine ducting system through the Taguchi-Pareto-DEMATEL method,” International Journal of Industrial Engineering and Engineering Management, vol. 4, no. 1, pp. 7-20, 2022.

Y. Abdullahi, S. A. Oke “Optimization the boring parameters on CNC machine using IS 2062 E250 steel plates: Taguchi-Pareto Box Behnken design and Taguchi-ABC-Box Behnken design perspective,” Engineering Access, vol. 8, no. 2, pp. 219-241, 2022.

S. C. Nwafor, S. A. Oke, C. A. Ayanladun “Factor analysis approach-Taguchi-Pareto method to casting A356 alloy composite for lightweight wheel rim cover of vehicles”, Journal IImiah Teknik Industri, vol. 10, no. 1, pp. 31-47, 2022.

M. C. Ikedue and S. A. Oke, “Optimization of wire electrical discharge machining parameters on AZ91 magnesium alloy using analytical hierarchy process-taguchi-based analyses”, Engineering Access, vol. 8, no. 2, 2023, in press.

A. Muniappan, M. Sriram, C. Thiagarajan, G. B. Raja, T. Shaafi, “Optimization of WEDM process parameters on machining of AZ91 Magnesium alloy using MOORA method,” IOP Conference Series: Materials Science and Engineering, vol. 390, pp. 012171, 2018.

Downloads

Published

How to Cite

Issue

Section

License

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.