Assessment of Stress-Strain Modeling for Reactive Powder Concrete Deep Beams

doi: 10.14456/mijet.2023.22

Keywords:

stress-strain model, material law, reactive powder concrete, deep beam, numerical analysisAbstract

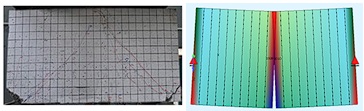

This study focuses on assessing the accuracy of the stress-strain model of concrete, as per the fib model code 2010, in simulating the behavior of deep beams made of reactive powder concrete (RPC). RPC is a modern concrete classified as an ultra-high performance fiber reinforced concrete. The study utilizes finite element analysis (FEA) to obtain numerical results for deep beams and compares them with experimental data gathered from existing literature. The investigation involves three types of deep beams: normal strength concrete (NSC), high strength concrete (HSC), and RPC, allowing for comprehensive comparisons. The findings from the FEA reveal that the fib model code 2010 provides conservative estimations for the loading capacity of RPC deep beams. Consequently, it is recommended that a stress-strain model specially tailored for RPC be implemented to achieve simulation results that closely align with experimental results.

References

C. Shi, Z. Wu, J. Xiao, D. Wang, Z. Huang, and Z. Fang, "A review on ultra high performance concrete: Part I. Raw materials and mixture design," Construction and Building Materials, vol. 101, pp. 741-751, 2015.

B. Chen, J. Zhou, D. Zhang, J. Su, C. Nuti, and K. Sennah,"Experimental study on shear performances of ultra-high performance concrete deep beams," Structures, vol. 39, pp. 310-322, 2022.

O. Q. Aziz, and M. H. Ali, "Shear strength and behavior of ultra-high performance fiber reinforced concrete (UHPC) deep beams without web reinforcement," Int. J. Civil Eng. Struct, vol. 2, pp. 85-96, 2013.

H. M. Fahmi, I. A. AlShaarbaf and A.S. Ahmed, "Behavior of reactive powder concrete deep beams," AL-Mansour Journal, vol. 20, no.1, pp. 1-22, 2013.

A.M. Yousef, A.M. Tahwia, and N. A. Marami, "Minimum shear reinforcement for ultra-high performance fiber reinforced concrete deep beams," Construction and Building Materials, vol. 184, pp. 177-185, 2018.

Comit´e Euro-International du Beton (CEB-FIP). "fib Model Code for Concrete Structures." International Federation for Structural Concrete (fib), Lausanne, Switzerland. 2010.

AG, S. "SOFiSTiK [Finite element program-Educational Version]." 2022.

Lusas. Modified Newton-Raphson Methods. 2022 29 November 2022 Available: https://www.lusas.com/user_area/theory/Nonlinear_Modified_Newton.html#:~:text=Three%20common%20forms%20of%20modified,second%20iterations%20of%20each%20increment. [Accessed: October. 4, 2023].

Downloads

Published

How to Cite

Issue

Section

License

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.