The Predicting The Optimal Compressive Strength of Sustainable Brick Using Response Surface Method (RSM)

Keywords:

Brick, CCD, Epoxy, PET, RSMAbstract

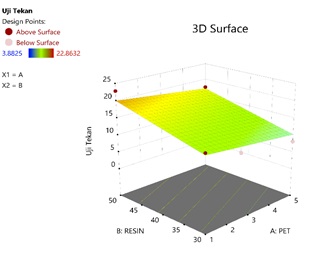

This research uses the Responses Surface Method (RSM) approach to make and optimize environmentally friendly bricks using a PET and epoxy resin mixture. The main input factors for the mixture are PET particles and epoxy resin as adhesive materials, while compressive strength is the primary response of the sustainable brick produced. RSM-based Central Composite Design (CCD) was used to assess the influence of PET particle variables (1-5mm) and epoxy resin ratio (30-50%) on the compressive strength response. The accuracy of the mathematical model created by CCD was tested using ANOVA. The RSM evaluation results show that the empirical findings suit linear and quadratic models for cost response and compressive strength. A coefficient of determination greater than 0.85 for all reactions indicates that the model can explain response variability. The optimization results show that the input variables PET particle and epoxy resin ratio have an average optimum value of 40% epoxy resin, each with a PET size of 3 mm. This optimal combination produces a maximum compressive strength of 13.37 MPa. The study and application of a mixture of PET particles and epoxy resin in making sustainable bricks has shown that these materials have great potential to increase the compressive strength of sustainable bricks.

References

M. Haqq and others, “Implementation of waste banks for reduction of solid waste in South Surabaya,” in MATEC Web of Conferences, 2019, p. 6021.

C. Mukherjee, J. Denney, E. G. Mbonimpa, J. Slagley, and R. Bhowmik, “A review on municipal solid waste-to-energy trends in the USA,” Renewable and Sustainable Energy Reviews, vol. 119, p. 109512, 2020.

D. Wulandari, S. H. Utomo, and B. S. Narmaditya, “Waste bank: Waste management model in improving local economy,” International Journal of Energy Economics and Policy, vol. 7, no. 3, pp. 36–41, 2017.

A. Kholil, M. Budiaman, and A. A. Jumhur, “Waste management based on 3R in mutiara waste banks Bekasi City Indonesia,” World Environment, vol. 8, no. 3, pp. 71–76, 2018.

W. Xue, K. Cao, and W. Li, “Municipal solid waste collection optimization in Singapore,” Applied Geography, vol. 62, pp. 182–190, 2015.

M. Frigione, “Recycling of PET bottles as fine aggregate in concrete,” Waste management, vol. 30, no. 6, pp. 1101–1106, 2010.

S. Perera, A. Arulrajah, Y. C. Wong, S. Horpibulsuk, and F. Maghool, “Utilizing recycled PET blends with demolition wastes as construction materials,” Construction and building materials, vol. 221, pp. 200–209, 2019.

N. Fatchurrohman, G. W. Kang, and M. I. Adelino, “Product Development And Performance of Reinforced Metal Matrix Composite Brake Disc: Modelling, Simulation And Multi-Criteria Decision Making Technique,” Spektrum Industri, vol. 19, no. 2, p. 105, Oct. 2021, doi: 10.12928/si.v19i2.21951.

M. Ijaz, S. R. Ahmad, M. Akram, W. U. Khan, N. A. Yasin, and F. A. Nadeem, “Quantitative and qualitative assessment of musculoskeletal disorders and socioeconomic issues of workers of brick industry in Pakistan,” International Journal of Industrial Ergonomics, vol. 76, p. 102933, 2020.

S. Tighe, T. Smith, and R. Fung, “Concrete Pavements in Canada: A Review of their Usage and Performance,” in Paper for Transportation Association of Canada Annual Conference, 2001.

I. I. Akinwumi, A. H. Domo-Spiff, and A. Salami, “Marine plastic pollution and affordable housing challenge: Shredded waste plastic stabilized soil for producing compressed earth bricks,” Case Studies in Construction Materials, vol. 11, p. e00241, 2019.

R. Bhushaiah, S. Mohammad, and D. S. Rao, “Study of plastic bricks made from waste plastic,” International Research Journal of Engineering and Technology, vol. 6, no. 4, p. 6, 2019.

S. Dinesh, A. Dinesh, and K. Kirubakaran, “Utilisation of waste plastic in manufacturing of bricks and paver blocks,” International journal of applied engineering research, vol. 2, no. 4, pp. 364–368, 2016.

S. K. Intan and S. Santosa, “Utilization of PTE and LDPE plastic waste and building material waste as bricks,” Korean Journal of Materials Research, vol. 29, no. 10, pp. 603–608, 2019.

H. Limami, I. Manssouri, K. Cherkaoui, and A. Khaldoun, “Study of the suitability of unfired clay bricks with polymeric HDPE & PET wastes additives as a construction material,” Journal of Building Engineering, vol. 27, p. 100956, 2020.

K. Zhou, Q. Liu, J. Feng, T. Chang, and J. Liu, “Comprehensive environmental performance of bottle-to-bottle recycling of PET bottles based on deposit-refund system in China,” Waste Management, vol. 172, pp. 90–100, 2023.

M. U. Hossain, S. T. Ng, P. Antwi-Afari, and B. Amor, “Circular economy and the construction industry: Existing trends, challenges and prospective framework for sustainable construction,” Renewable and Sustainable Energy Reviews, vol. 130, p. 109948, 2020.

K. Rashid, E. U. Haq, M. S. Kamran, N. Munir, A. Shahid, and I. Hanif, “Experimental and finite element analysis on thermal conductivity of burnt clay bricks reinforced with fibers,” Construction and Building Materials, vol. 221, pp. 190–199, 2019.

M. Mahdaoui et al., “Building bricks with phase change material (PCM): Thermal performances,” Construction and Building Materials, vol. 269, p. 121315, 2021.

J. O. Akinyele, U. T. Igba, T. O. Ayorinde, and P. O. Jimoh, “Structural efficiency of burnt clay bricks containing waste crushed glass and polypropylene granules, Case Stud,” Const. Mater, vol. 13, pp. 1–11, 2020.

B. Debska and L. Lichołai, “The selected mechanical properties of epoxy mortar containing PET waste,” Construction and Building materials, vol. 94, pp. 579–588, 2015.

A. Gregori, M. Mercuri, M. Angiolilli, and M. Pathirage, “Simulating defects in brick masonry panels subjected to compressive loads,” Engineering Structures, vol. 263, p. 114333, 2022.

P. Munoz, M. A. Mend’ivil, V. Letelier, and M. P. Morales, “Thermal and mechanical properties of fired clay bricks made by using grapevine shoots as pore forming agent. Influence of particle size and percentage of replacement,” Construction and Building Materials, vol. 224, pp. 639–658, 2019.

P. R. Pati, “Characterization of glass-epoxy composites using red brick dust particles,” Materials Today: Proceedings, vol. 18, pp. 3775–3779, 2019.

S.-Y. Guo et al., “Mechanical and interface bonding properties of epoxy resin reinforced Portland cement repairing mortar,” Construction and Building Materials, vol. 264, p. 120715, 2020.

N. George, T. K. B. Sharmila, and T. Kurian, “Preparation of a one-component epoxy adhesive using PET bottle waste derived terephthalic dihydrazide as latent curing agent,” International Journal of Adhesion and Adhesives, vol. 98, p. 102524, 2020.

A. Deriszadeh, F. Shahraki, D. M. Kalhori, and O. M. Jazani, “Epoxy/GO nanocomposite adhesives reinforced with waste blends of PET/GTR: Evaluation of mechanical properties,” Progress in Organic Coatings, vol. 136, p. 105292, 2019.

P. L. Paihte, A. C. Lalngaihawma, and G. Saini, “Recycled Aggregate filled waste plastic bottles as a replacement of bricks,” Materials Today: Proceedings, vol. 15, pp. 663–668, 2019.

O. Adiyanto, E. Mohamad, R. Jaafar, and M. Faishal, “Identification of Musculoskeletal Disorder among Eco-Brick Workers in Indonesia,” International Journal of Occupational Safety and Health, vol. 13, no. 1, pp. 29–40, 2023.

S. N. Amir and N. Z. Yusof, “Plastic in brick application,” Trends in Civil Engineering and its Architecture, vol. 3, no. 1, p. 4, 2018.

M.-H. Wu, C.-L. Lin, W.-C. Huang, and J.-W. Chen, “Characteristics of pervious concrete using incineration bottom ash in place of sandstone graded material,” Construction and Building Materials, vol. 111, pp. 618–624, 2016.

O. Adiyanto, E. Mohamad, Irianto, R. Jaafar, M. Faishal, and M. I. Rasyid, “Optimization of PET Particle-Reinforced Epoxy Resin Composite for Eco-Brick Application Using the Response Surface Methodology,” Sustainability, vol. 15, no. 5, p. 4271, 2023.

M. Abdulgader, Q. J. Yu, A. A. Zinatizadeh, P. Williams, and Z. Rahimi, “Application of response surface methodology (RSM) for process analysis and optimization of milk processing wastewater treatment using multistage flexible fiber biofilm reactor,” Journal of Environmental Chemical Engineering, vol. 8, no. 3, p. 103797, 2020.

K. E. Alyamac, E. Ghafari, and R. Ince, “Development of eco-efficient self-compacting concrete with waste marble powder using the response surface method,” Journal of cleaner production, vol. 144, pp. 192–202, 2017.

M. A. Bezerra, R. E. Santelli, E. P. Oliveira, L. S. Villar, and L. A. Escaleira, “Response surface methodology (RSM) as a tool for optimization in analytical chemistry,” Talanta, vol. 76, no. 5, pp. 965–977, 2008.

N. Mohamad Yatim, A. Shaaban, M. F. Dimin, F. Yusof, J. Abd Razak, and others, “Application of response surface methodology for optimization of urea grafted multiwalled carbon nanotubes in enhancing nitrogen use efficiency and nitrogen uptake by paddy plants,” Journal of Nanotechnology, vol. 2016, 2016.

U. A. Toor, T. T. Duong, S.-Y. Ko, F. Hussain, and S.-E. Oh, “Optimization of Fenton process for removing TOC and color from swine wastewater using response surface method (RSM),” Journal of Environmental Management, vol. 279, p. 111625, 2021.

A. Habibi, A. M. Ramezanianpour, M. Mahdikhani, and O. Bamshad, “RSM-based evaluation of mechanical and durability properties of recycled aggregate concrete containing GGBFS and silica fume,” Construction and Building Materials, vol. 270, p. 121431, 2021.

E. W. Elsayed and M. F. Emam, “Application of Response Surface Methodology Using Face-centered Central Composite Design for Studying Long-Term Stability of Gliclazide-Loaded Multiparticulate Systems,” Journal of Pharmaceutical Sciences, 2024.

H. Karyab, M. Ghasemi, F. Ghotbinia, and N. Nazeri, “Efficiency of chitosan nanoparticle with polyaluminum chloride in dye removal from aqueous solutions: Optimization through response surface methodology (RSM) and central composite design (CCD),” International Journal of Biological Macromolecules, vol. 249, p. 125977, 2023.

M. Yan et al., “Design and evaluation of a novel heliostat-based combined cooling, heating, and power (CCHP) system: 3E analysis and multi-criteria optimization by response surface methodology (RSM),” Energy, vol. 285, Dec. 2023, doi: 10.1016/j.energy.2023.129389.

R. T. Mushtaq et al., “Multi-objective optimization of laser polishing parameters for enhanced mechanical properties, sustainability, and surface finish of 3D-Printed industrial ABS polymers using response surface methodology (RSM),” Journal of Materials Research and Technology, vol. 29, pp. 3168–3184, Mar. 2024, doi: 10.1016/j.jmrt.2024.02.023.

P. Zafari and A. Ghaemi, “Mixed MDEA-PZ amine solutions for CO2 capture: Modeling and optimization using RSM and ANN approaches,” Case Studies in Chemical and Environmental Engineering, vol. 8, Dec. 2023, doi: 10.1016/j.cscee.2023.100509.

Y. Luo, P. Guo, J. Gao, J. Meng, and Y. Dai, “Application of Design-Expert response surface methodology for the prediction of rejuvenated asphalt fatigue life,” Journal of Cleaner Production, vol. 379, p. 134427, 2022.

R. Chikati, T. A. Mpandanyama, D. Nkazi, P. Khangale, and J. Gorimbo, “Optimization and evaluation of the distribution of Fischer-Tropsch products over a cobalt-based catalyst utilising design expert software,” Heliyon, vol. 10, no. 1, 2024.

W. Ferdous et al., “Optimal design for epoxy polymer concrete based on mechanical properties and durability aspects,” Constr Build Mater, vol. 232, p. 117229, 2020.

W. Boransan, T. Kerdphol, and V. Phunpeng, “Experimental Manufacturing Methods of Glass Fiber Composites Considering Flexural Behaviour,” Spektrum Industri, vol. 19, no. 2, p. 87, Oct. 2021, doi: 10.12928/si.v19i2.21658.

X. Kang, Y. Gan, R. Chen, and C. Zhang, “Sustainable eco-friendly bricks from slate tailings through geopolymerization: synthesis and characterization analysis,” Construction and Building Materials, vol. 278, p. 122337, 2021.

K. Suresh, “Recycling of fly ash for development of value added products,” Materials Today: Proceedings, vol. 46, pp. 5666–5674, 2021.

S. Dixit and V. L. Yadav, “Optimization of polyethylene/polypropylene/alkali modified wheat straw composites for packaging application using RSM,” Journal of Cleaner Production, vol. 240, p. 118228, 2019.

H. Fang et al., “Ultra-sensitive nanoprobe modified with tumor cell membrane for UCL/MRI/PET multimodality precise imaging of triple-negative breast cancer,” Nano-micro letters, vol. 12, pp. 1–14, 2020.

M. E. Imanian and F. R. Biglari, “Modeling and prediction of surface roughness and dimensional accuracy in SLS 3D printing of PVA/CB composite using the central composite design,” Journal of Manufacturing Processes, vol. 75, pp. 154–169, 2022.

M. Z. Hassan, S. M. Sapuan, S. A. Roslan, S. Sarip, and others, “Optimization of tensile behavior of banana pseudo-stem (Musa acuminate) fiber reinforced epoxy composites using response surface methodology,” Journal of Materials Research and Technology, vol. 8, no. 4, pp. 3517–3528, 2019.

D. Sinkhonde, R. O. Onchiri, W. O. Oyawa, and J. N. Mwero, “Response surface methodology-based optimisation of cost and compressive strength of rubberised concrete incorporating burnt clay brick powder,” Heliyon, vol. 7, no. 12, 2021.

A. P. King, “225Ac-MACROPATATE: a novel $α$-particle peptide receptor radionuclide therapy for neuroendocrine tumors,” Journal of Nuclear Medicine, vol. 64, no. 4, pp. 549–554, 2023.

Downloads

Published

How to Cite

Issue

Section

License

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.