Effects of Admixtures on Geopolymer Concrete

DOI:

https://doi.org/10.55674/snrujiti.v1i1.246612Keywords:

Geopolymer concrete, Bagasse ash, Admixtures, Compressive strength, WorkabilityAbstract

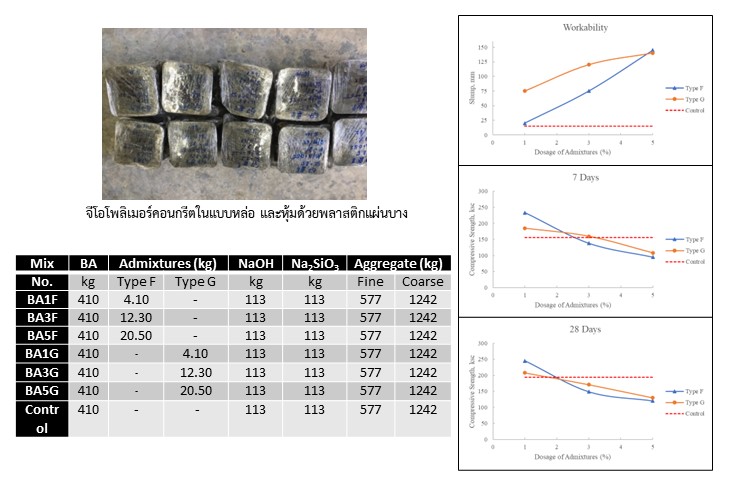

This research applied the bagasse ash which is a waste from the sugar mill industry to produce Geopolymer concrete. This type of concrete reduces the environmental effect. The bagasse ash was ground until the residual particle retained on sieve No. 325 less than 5percent. Two types of superplasticizers, namely, Type F and Type G were applied to the mixtures. The results of showed that the using of both superplasticizers improved the workability of Geopolymers concrete as increasing amount of usage. The superplasticizer Type G exhibited the highest workability. On the other hand, it was found that the compressive strength of geopolymer concrete decreased with higher workability. It was found that the using of superplasticizer at 1% was suitable for geopolymer concrete.

References

ASTM. (1996). C430-96. Standard test method for fineness of hydraulic cement. West Conshohocken, PA, USA: ASTM.

Bosoaga, A., Masek, O., & Oakey, J. E. (2009). CO2 capture technologies for cement industry. Energy procedia, 1(1), 133-140.

Joshaghani, A., & Moeini, M. A. (2017). Evaluating the effects of sugar cane bagasse ash (SCBA) and nanosilica on the mechanical and durability properties of mortar. Construction and building materials, 152, 818-831.

อดิศักดิ์ ชนะพันธ์, & สหลาภ หอมวุฒิวงศ์. (2021). การพัฒนาจีโอโพลิเมอร์คอนกรีตที่ผลิต จากเถ้าชานอ้อย และตะกอนน้ำประปาเผา. UBU Engineering Journal, 14(3), 63-75.

Homwuttiwong, S. (2020). ปัจจัยที่มีผลต่อกำลังรับแรงอัดของจีโอโพลิเมอร์คอนกรีต จาก เถ้าชานอ้อยผสมเศษอะลูมิเนียม. Naresuan University Engineering Journal, 15(2), 65-74.

Kittisayarm, P., Pantongsuk, T., Srikhacha, A., Chaysuwan, D., & Tippayasam, C. (2020). Development of High-Strength Geopolymers by High-Reactive Bagasse Ash. The Journal of Industrial Technology, 16(3), ุ-66.

ASTM, C. 494/C 494 M. (2005). Standard Specification for Chemical Admixtures for Concrete. ASTM International.

ASTM, C. 143/C-143 M, 2000. Standard Test Method for Slump of Hydraulic-Cement Concrete.

ASTM C 192-98. (1998). Standard practice for making and curing concrete test specimens in the laboratory.

BS EN 12390-2. (2009). Testing hardened concrete. Making and curing specimens for strength tests.

ASTM, C. 39. (2014) Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. West Conshohocken, PA: ASTM International.

BS EN 12390-3. (2009). Testing hardened concrete. Compressive strength of test specimens. British Standard Institution.

Muhit, I. B. (2013). Dosage limit determination of super plasticizing admixture and effect evaluation on properties of concrete. International Journal of Scientific & Engineering Research, 4(3), 1-4.

Nuruddin, F., Demie, S., Memon, F. A., & Shafiq, N. (2011). Effect of superplasticizer and NaOH molarity on workability, compressive strength and microstructure properties of self-compacting geopolymer concrete. World Academy of Science, Engineering and Technology, 75.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2022 Journal of Industrial Technology and Innovation

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.