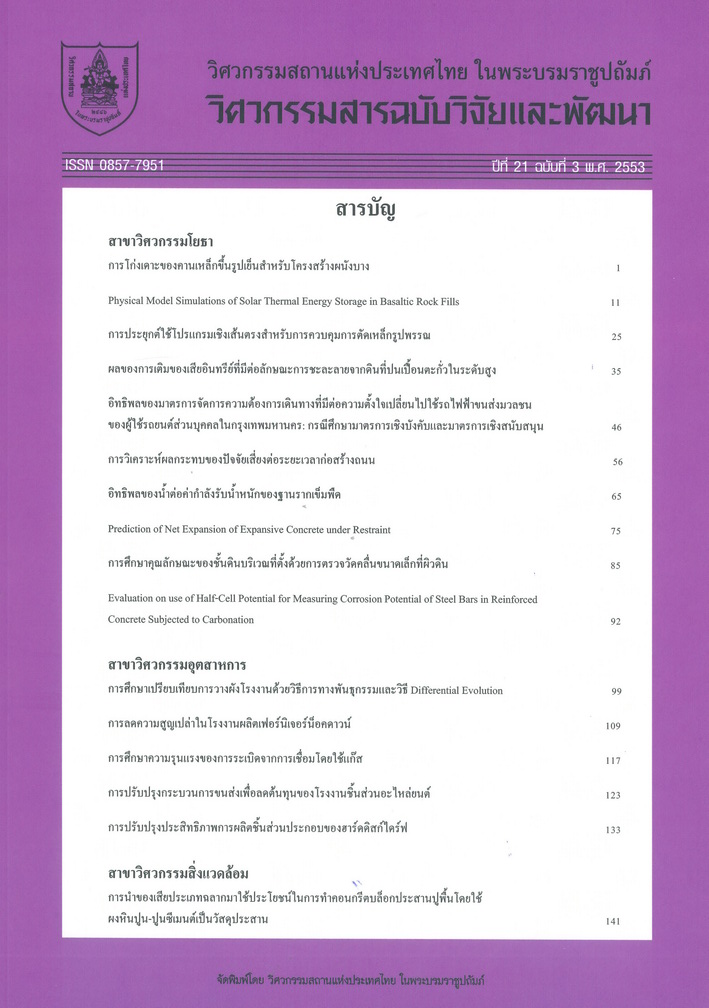

การปรับปรุงประสิทธิภาพการผลิตชิ้นส่วนประกอบของฮาร์ดดิสก์ไดร์ฟ

Main Article Content

Abstract

In this paper present the case of efficiency improvement in hard disk drive components manufacturing under this study is producing many varieties of products in small lots. This requires frequent changeovers, which results in production inefficiency and late deliveries. The current injection machine 43 mc and products 60 model An analysis & study that we can classification of products by 2 groups are discreate job and make to order job which the current make to order about 57 model revealed that the major causes of productivity loss are setups by use set up time about 5 hrs per time Therefore, the productivity improvement in this study concentrates on developeding new setup method to reduce setup-time uses the SMED (Single-Minute Exchange of Dies) techniques developed by Shingo in conjunction with work study techniques for analysis and design. The improvements result in the reduction of late deliveries time 12% to 2% and reduction of set up time from 30.2% of the machine available time to 12 %

Article Details

The published articles are copyright of the Engineering Journal of Research and Development, The Engineering Institute of Thailand Under H.M. The King's Patronage (EIT).