Emissions of CH4 and CO2 from Wastewater of Palm Oil Mills: A Real Contribution to Increase the Greenhouse Gas and Its Potential as Renewable Energy Sources 10.32526/ennrj/20/202100149

Main Article Content

Abstract

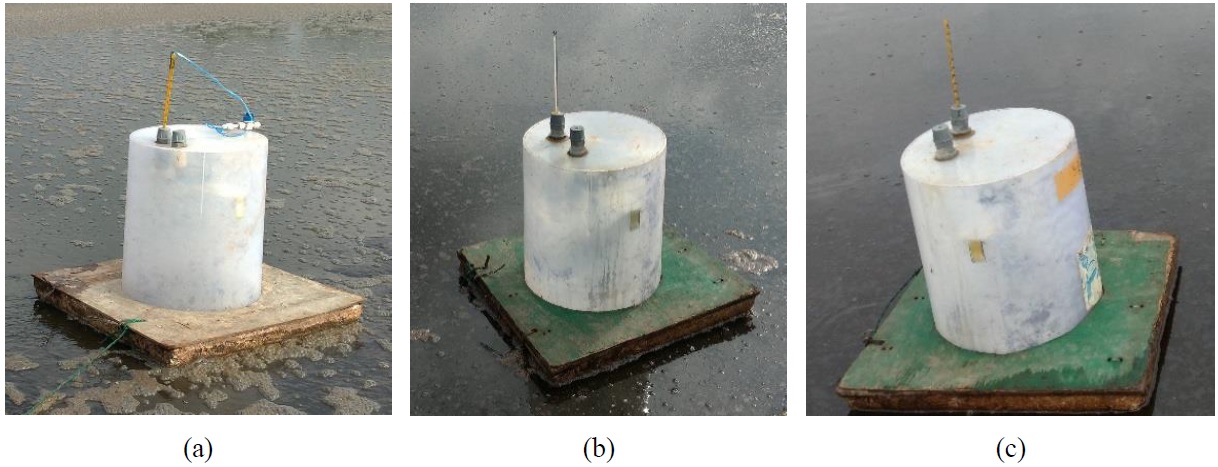

Palm oil mill effluent (POME) treatment in Indonesia is still predominant using an open pond system. This system has the weakness of the unknown and uncontrollable value of greenhouse gas (GHG) emissions into the atmosphere. This study estimated GHG emissions (CH4 and CO2) from anaerobic ponds and their potential as a renewable energy source and obtain GHG emission conversion coefficients for each kg of COD POME and ton of crude palm oil (CPO). Gas samples were collected using a closed static chamber. GHG sample concentration testing was done using Gas Chromatography with a flame ionization detector (FID) and thermal conductivity detector (TCD). The results showed that the emission rate of CH4 and CO2 in the anaerobic pond POME treatment was relatively high, 261.93 and 595.99 g/m2/day, respectively, equivalent to 48.572 t CO2-eq/day or 14,571.5 t CO2-eq/year. CO2 emissions were greater than two times CH4 emissions, both spatially and temporally. There was a process of facultative biodegradation, aerobic and or anaerobic process according to the biotic-abiotic environment and the levels of organic components in the substrate. In anaerobic ponds, the optimal requirements for the biodegradation process tended to be unfulfilled, so the emission rate of CH4 was less than CO2. The GHG conversion coefficient was obtained, namely each kg of COD from POME emitted 6.266 kg CO2-eq of GHG; for each m3 of POME emitted by 0.163 t CO2-eq of GHG; and 0.556 t CO2-eq/t CPO. The maximum potential for POME to energy conversion was 1.045 MWe with a power capacity of 8,603 MWh/year.

Article Details

Published articles are under the copyright of the Environment and Natural Resources Journal effective when the article is accepted for publication thus granting Environment and Natural Resources Journal all rights for the work so that both parties may be protected from the consequences of unauthorized use. Partially or totally publication of an article elsewhere is possible only after the consent from the editors.

References

Ahmed Y, Yaakob Z, Akhtar P, Sopian K. Production of biogas and performance evaluation of existing treatment processes in palm oil mill effluent (POME). Renewable and Sustainable Energy Reviews 2015;42:1260-78.

Alkusma YM, Hermawan, Hadiyanto. Development of alternative energy potential by utilizing palm oil liquid waste as a new renewable energy source in East Kotawaringin Regency. Jurnal Ilmu Lingkungan 2016;14(2):96-102.

American Public Health Association (APHA). Standard Methods for the Examination of Water and Wastewater. Washington DC, USA: American Public Health Association, American Water Works Association, and Water Environment Federation; 1998.

Arif C, Setiawan BI, Widodo S, Rudiyanto, Hasanah NAI, Mizoguchi M. Development of artificial neural network models to estimate greenhouse gas emissions from rice fields with various water regimes. Jurnal Irigasi 2015;10(1):1-10.

Aziz MMA, Kassim KA, Elsergany M, Anuar S, Jorat ME, Yaacob H, et al. Recent advances on palm oil mill effluent (POME) pretreatment and anaerobic reactor for sustainable biogas production. Renewable and Sustainable Energy Reviews 2019;119:1-14.

Batstone DJ. Mathematical modelling of anaerobic reactors treating domestic wastewater: Rational criteria for model use. Reviews in Environmental Science and Biotechnology 2006;5:57-71.

Chen W, Wolf B, Zheng X, Yao Z, Butterbach-Bahl K, Brüggemann N, et al. Annual methane uptake by temperate semiarid steppes as regulated by stocking rates, aboveground plant biomass and topsoil air permeability. Global Change Biology 2011;17:2803-16.

Choong YY, Chou KW, Norli I. Strategies for improving biogas production of palm oil mill effluent (POME) anaerobic digestion: A critical review. Renewable and Sustainable Energy Reviews 2017;82:2993-3006.

Coombs J. The Present and Future of Anaerobic Digestion. New York, USA: Elsevier Science Publishing Co.Inc.; 1991.

Deublein D, Steinhauser A. Biogas from Waste and Renewable Resources an Introduction. Weinheim, Germany: Wiley-VCH Verlag GmbH and Co. KGaA; 2008.

Drapcho CM, Nhuan NP, Walker TH. Biofuels Engineering Proces Technology. USA: McGraw-Hill Companies Inc.; 2008.

El-Fadel M, Massoud M. Methane emissions from wastewater management. Environmental Pollution 2001;114(2):177-85.

Febijanto I. Potential for catching methane gas and its use as fuel for power generation at PTPN VI Jambi. Jurnal Ilmiah Teknologi Energi 2010;1(10):30-47.

Febijanto I. Optimization of methane gas use as energy resource in palm oil mill as an anticipated selling price of electricity based on the existing average cost of generation. Jurnal Teknologi Lingkungan 2018;19(1):49-60.

Foong SZY, Chong MF, Ng DKS. Strategies to promote biogas generation and utilisation from palm oil mill effluent. Process Integration and Optimization for Sustainability 2021;5: 175-91.

Hassan MA, Yacob S, Shirai Y. Treatment of palm oil wastewaters. In: Wang LK, Hung Y, Lo HH, Yapijakis C, editors. Handbook of Industrial and Hazardous Wastes Treatment. New York, USA: Marcel Dekker, Inc.; 2004. p. 719-36.

Hosseini SE, Wahid MA. Pollutant in palm oil production process. Journal of the Air and Waste Management Association 2015;65(7):773-81.

Indonesian Palm Oil Association (IPOA). Palm Oil Industry Reflection 2016 and Prospects 2017. Jakarta, Indonesia: Indonesian Palm Oil Association; 2017.

Intergovernmental Panel on Climate Change (IPCC). IPCC Guidelines for National Greenhouse Gas Inventories: Volume 1-5. Hayama, Japan: Institute for Global Environmental Strategies; 2006.

International Atomic Energy Agency (IAEA). Manual on Measurement of Methane and Nitrous Oxide Emissions from Agriculture. Vienna, Austria: Food and Agriculture Organization of The United Nations and International Atomic Energy Agency; 1992.

Khokhar NH, Park J. A simplified sampling procedure for the estimation of methane emission in rice fields. Environmental Monitoring and Assessment 2017;189:1-10.

Korres NE, O'Kiely P, Benzie JAH, West JS. Bioenergy Production by Anaerob Digester, Using Agricultural Biomass and Organic Waste. Maryland, USA: Taylor and Francis; 2013.

Lam MK, Lee KT. Renewable and sustainable bioenergies production from palm oil mill effluent (POME): Win-win strategies toward better environmental protection. Biotechnology Advances 2011;29:124-41.

Lam WY, Kulak M, Sim S, King H, Huijbregts MAJ, Chaplin-Kramer R. Greenhouse gas footprints of palm oil production in Indonesia over space and time. Science of the Total Environment 2019;688:827-37.

Lantin RS, Aduna JB, Javeliana AM. Methane Measurements in Rice Fields. Manila, Philippines: International Rice Research Institute; 1995.

Mahajoeno E. Development of Renewable Energy from Palm Oil Mill Wastewater [dissertation]. Bogor, Indonesia: Bogor Agricultural Institute; 2008.

Ministry of Agriculture. Statistics of Indonesian Estates 2015-2017 Palm Oil. Jakarta, Indonesia: Ministry of Agriculture; 2016.

Ministry of Agriculture. Tree Crop Estate Statistics of Indonesia 2017-2019 Palm Oil. Jakarta, Indonesia: Ministry of Agriculture; 2018.

Morad N, Choo SS, Hoo YC. Simplified life cycle assessment of crude palm oil: A case study at a palm oil mill. Proceedings of the International Conference on Environmental Research and Technology 2008 (ICERT 08); 2008 May 28-30; Parkroyal Hotel, Pulau Pinang: Malaysia; 2008.

Moriarty K, Elchinger M, Hill G, Katz J, Barnett J. Methane for Power Generation in Muaro Jambi: A Green Prosperity Model Project. Colorado, USA: National Renewable Energy Laboratory (NREL); 2014.

Nguyen D, Wu Z, Shrestha S, Lee PH, Raskin L, Khanal SK. Intermittent micro-aeration: New strategy to control volatile fatty acid accumulation in high organic loading anaerobic digestion. Water Research 2019;166:1-10.

Nguyen DM. Oxidation-Reduction Potential-Based Micro-Aeration Control System for Anaerobic Digestion [dissertation]. Honolulu, USA: University of Hawaii at Mānoa; 2018.

Ohimain EI, Izah SC. A review of biogas production from palm oil mill effluents using different configurations of bioreactors. Renewable and Sustainable Energy Reviews 2017;70:242-53.

Paredes MG, Güerecaa LP, Molinab LT, Noyolaa A. Methane emissions from stabilization ponds for municipal wastewater treatment in Mexico. Journal of Integrative Environmental Sciences 2015;12(SI):139-53.

Park JBK, Craggs RJ. Biogas production from anaerobik waste stabilisation ponds treating dairy and piggery wastewater in New Zealand. Water Science and Technology 2007; 55(11):257-64.

Pehnelt G, Vietze C. Recalculating GHG emissions saving of palm oil biodiesel. Environmental Monitoring and Assessment 2013;15:429-79.

Prasetya H, Arkeman Y, Hambali E. Role of methane capture for sustainable biodiesel production from palm oil: A life cycle assessment approach. International Journal on Advanced Science, Engineering and Information Technology 2013;3(5):17-20.

Putro LHS, Budianta D, Rohendi D, Rejo A. Biomethane emissions: Measurement in wastewater pond at palm oil mill by using TGS2611 methane gas sensor. Journal of Ecological Engineering 2019;20(6):25-35.

Putro LHS, Budianta D, Rohendi D, Rejo A. Modeling methane emission of wastewater anaerobic pond at palm oil mill using radial basis function neural network. International Journal on Advanced Science, Engineering and Information Technology 2020;10(1):260-8.

Putro LHS. Biomethane from Palm Oil Mill Effluent: An Overlooked Renewable Energy Sources. Depok, Indonesia: Rajawali Pers; 2021.

Rahayu AS, Karsiwulan D, Yuwono H, Paramita V. Guide Book for Converting POME into Biogas: Project Development in Indonesia. Jakarta, Indonesia: Winrock International; 2015.

Sarono. The Greenhouse Gas Reduction Strategy through Conversion of Palm Oil Mill Liquid Waste into Electrical Energy (Case Study in Lampung Province) [dissertation]. Bogor, Indonesia: Bogor Agricultural Institute; 2014.

Schuchardt F, Wulfert K, Darnoko, Herawan T. Effect of new palm oil mill processes on the EFB and POME utilization. Journal Oil Palm Research 2008;Special Issue:115-26.

Seadi TA, Rutz D, Prassl H, Köttner D, Finsterwalder D, Volk S, et al. Biogas Handbook. Esbjerg, Denmark: University of Southern Denmark; 2008.

Setyanto P, Wihardjaka A, Yulianingsih E, Agus F. Greenhouse gas emissions from drainage channels in Jabiren peatlands, Central Kalimantan. In: Wihardjaka, A, Maftu'ah E, editors. Proceedings of the National Seminar: Sustainable Management of Degraded Peatlands for GHG Emission Mitigation and Economic Value Enhancement; 2014 Aug 18-19; Jakarta: Indonesia; 2014.

Speece RE. Anaerobic Biotechnology for Industrial Wastewaters. Tennessee, USA: Archae Press; 1996.

Suprihatin, Sa’id EG, Suparno O, Sarono. Palm oil mill wastewater potential as an alternative energy sources. Prosiding Seminar Nasional PERTETA; 2012 Nov 30 - Dec 2; Malang: Indonesia; 2012 (in Indonesian).

Tanaka N. Energy Sector Methane Recovery and Use: The Importance of Policy. Paris, France: International Energy Agency (IEA); 2009.

Taniwiryono D, Siswanto, Herman. Policy and Financial Analysis for Development of Biogas Power Plant in Palm Oil Mills “Towards Low Carbon Development in Oil Palm Sector”. Jakarta, Indonesia: Coordinating Ministry for Economic Affairs; 2016.

Wall G, Hammond B, Donlon P, Johnson ND, Smith JC. Commissioning and operation of high rate anaerobic lagoon (HRAL) reactors. Proceedings of the 63rd Annual Water Industry Engineers and Operators Conference; 2000 Sep 6-7; Brauer College, Warrnambool: Australia; 2000.

Wu TY, Mohammad AW, Jahim JMd, Anuar N. Pollution control technologies for the treatment of palm oil mill effluent (POME) through end-of-pipe processes. Journal of Environment Management 2010;91:1467-90.

Yacob S, Hassan MA, Shirai Y, Wakisaka M, Subash S. Baseline study of methane emission from anaerobic ponds of palm oil mill effluent treatment. Science of the Total Environment 2006;366:187-96.

Yuliasari R, Darnoko, Wulfred K, Gindulis W. Oil palm wastewater treatment using fixed bed anaerobic reactor down-flow type. Warta Pusat Penelitian Kelapa Sawit 2001;9:75-81.