Color Removal of Pulp and Paper Mill Wastewater Using Residual Eucalyptus Wood 10.32526/ennrj/20/202200038

Main Article Content

Abstract

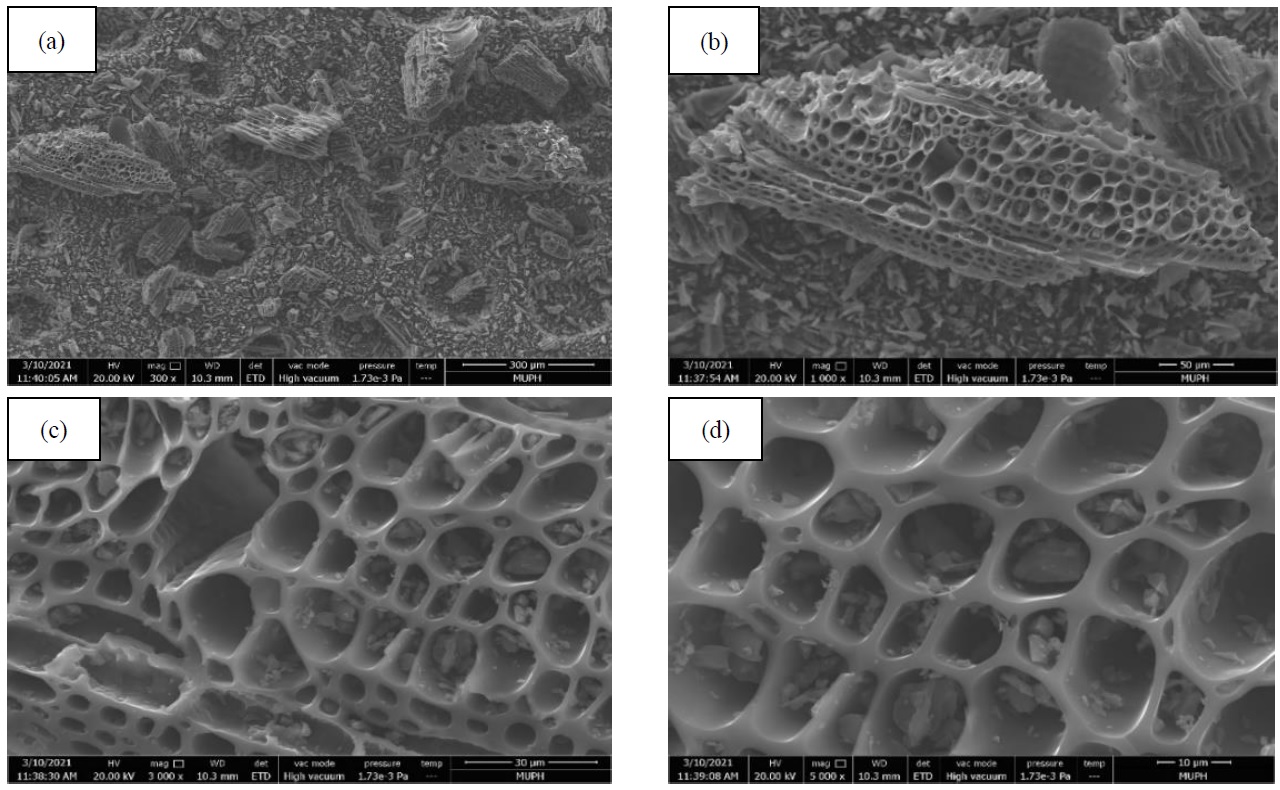

This study investigated the color removal efficiency of pulp and paper mill wastewater using residual eucalyptus wood as a method to minimize the solid wastes generated from pulp and paper processes. The activated carbon used in this study as the color adsorbent was produced from residual eucalyptus wood. The carbon was activated with phosphoric acid and carbonized in a furnace at 500°C for 60 min. Effects of types and amounts of activated carbon on color removal efficiency were evaluated. Three types of solid wastes, consisting of wood chip, bark, and mixed wood (wood chip:bark, 1:1), were investigated at a loading of 1, 3, 5, and 7 g/100 mL under contact times of 30, 60, 90, and 120 min. The results showed that 7 g of wood chip activated carbon/100 mL under all contact times gave color removal efficiency of 94-97%. However, the highest adsorption capacity of 216 ADMI/g occurred at 1 g of adsorbent used. Freundlich isotherms were satisfactorily fitted to experimental data for the best condition with high correlation coefficients. The color removal efficiency depended on surface area, pore volume, structure, and characteristics of the activated carbon.

Article Details

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.

Published articles are under the copyright of the Environment and Natural Resources Journal effective when the article is accepted for publication thus granting Environment and Natural Resources Journal all rights for the work so that both parties may be protected from the consequences of unauthorized use. Partially or totally publication of an article elsewhere is possible only after the consent from the editors.

References

Ahmad AA, Hameed BH. Reduction of COD and color of dyeing effluent from a cotton textile mill by adsorption onto bamboo-based activated carbon. Journal of Hazardous Materials 2009;172:1538-43.

Ministry of Natural Resources and Environment (MNRE). Announcement of the Ministry of Natural Resources and Environment: Establishing Standards for Controlling the Drainage of Pulp and Paper Factories. Thailand: Ministry of Natural Resources and Environment; 2018. p. 13-6.

Armstrong AD, Bentley KM, Galeano SF, Olszewski RJ, Smith GA, Smith JR. The Pulp and Paper Industry. In: The Ecology of Industry. Washington, DC: National Academy Press; 1998. p. 101-41.

Azha SF, Ismail S. Feasible and economical treatment of real hand-drawn batik/textile effluent using zwitterionic adsorbent coating: Removal performance and industrial application approach. Journal of Water Process Engineering 2021; 41:Article No. 102093.

Borgesa ACP, Onwudilib JA, Andradec HMC, Alves CT, Ingram A, Vieira de Melo SAB, et al. Catalytic supercritical water gasification of eucalyptus wood chips in a batch reactor. Journal of Fuel 2019;255:Article No. 115804.

Chooaksorn W. Color removal technology in industrial wastewater. Burapha Science Journal 2012;17:181-91.

Chuyingsakuntip S, Tangsathitkulchi C. Adsorption of natural aluminium dye complex from silk-dyeing effluent using eucalyptus wood activated carbon. American Journal of Analytical Chemistry 2013;4:379-86.

El maguana Y, Elhadiri N, Benchanaa M, Chikri R. Activated carbon for dyes removal: Modeling and understanding the adsorption process. Journal of Chemistry 2020;2020:Article No. 2096834.

El-Bestawy E, El-Sokkary I, Hussein H, Keela AFA. Pollution control in pulp and paper industrial effluents using integrated chemical-biological treatment sequences. Journal of Industrial Microbiology and Biotechnology 2008;35:1517-29.

Ferraz FM, Yuan Q. Performance of oat hulls activated carbon for COD and color removal from landfill leachate. Journal of Water Process Engineering 2020;33:Article No. 101040.

Kiatgrajai P, Laohathai B, Sangkul S. Charcoal Briquette from river red gum. Thai Journal Forestry 1994;13:38-49.

Kongsuwan A, Patnukao P, Pavasant P. Binary component sorption of Cu (II) and Pb (II) with activated carbon from Eucalyptus camaldulensis Dehn bark. Journal of Industrial and Engineering Chemistry 2009;15:465-70.

Kumar A, Srivastava NK, Gera P. Removal of color from pulp and paper mill wastewater-methods and techniques: A review. Journal of Environmental Management 2021;298:Article No. 113527.

Okeola O, Odebunmi E, Ameen O. Comparison of sorption capacity and surface area of activated carbon prepared from prepared from Jatropha curcas fruit pericarp and seed coat. Chemical Society of Ethiopia 2012;26(2):171-80.

Patnukao P, Pavasant P. Activated carbon from Eucalyptus camaldulensis Dehn bark using phosphoric acid activation. Journal of Bioresource Technology 2008;99:8540-43.

Pokhrel D, Viraraghavan T. Treatment of pulp and paper mill wastewater: A review. Science of the Total Environment 2004;333:37-58.

Rajahmundry GK, Garlapati C, Ponnusamy, Kumar S, Alwi RS, Vo DN. Statistical analysis of adsorption isotherm models and its appropriate selection. Chemosphere 2021;276:Article No. 130176.

Shi X, Xu C, Hu H, Tang F, Sun L. Characterization of dissolved organic matter in the secondary effluent of pulp and paper mill wastewater before and after coagulation treatment. Water Science and Technology 2016;74(6):1346-53.

Srimoon R. Dyes treatment in wastewater using adsorption processes. Khon Kaen University Science Journal 2016; 44(3):419-34.

Yadav R, Upadhyay K, Maru S. Colour removal from paper mill effluent using activated carbon. Journal of Industrial Pollution Control 2012;28(1):45-50.