Using Recycled Coal Ash from Thermal Power Plants and Rice Husk Ash as Alternative Aggregates for the Manufacturing of Terrazzo Tiles 10.32526/ennrj/23/20240221

Main Article Content

Abstract

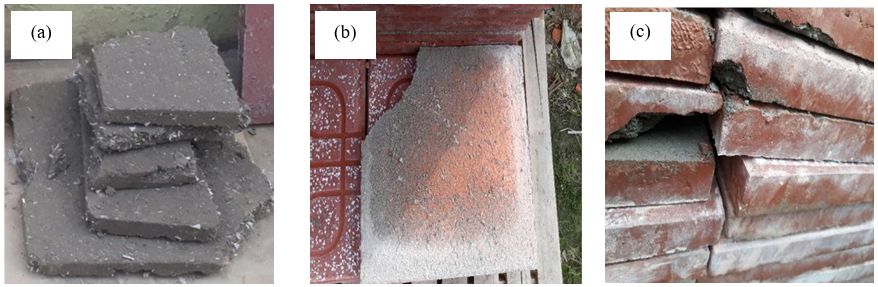

This study investigated the technical specifications of Terrazzo tiles manufactured using coal ash from thermal power plants and rice husk ash (RHA) to partially replace sand and cement as primary aggregates. Sample bricks with different mixed ratios of fly ash, bottom ash (slag), and RHA were produced with a hydrostatic-press machine with a standard mode of 400×400×30 mm. Our results showed that the brick density, flexural strength, and water absorption were significantly affected by the variation of fly ash and RHA content. The optimum ratio by weight of aggregate ingredients was found to be fly ash of 10%wt., RHA of 30%wt., and slag of 5%wt., accompanied by crushed stone at 55%wt. This produced brick products comparable to Terrazzo tiles, type 2, Mac 4.0. This classification satisfies the Vietnamese national standard for exterior bricks, and also is competitive with commercial quality in the local market. The reuse and recycling of waste from thermal power plants and RHA for manufacturing new construction material was thus demonstrated successfully in this study. This helps to emphasize the trend of net zero emissions, and further encourages the concept of reutilization towards sustainable development.

Article Details

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.

Published articles are under the copyright of the Environment and Natural Resources Journal effective when the article is accepted for publication thus granting Environment and Natural Resources Journal all rights for the work so that both parties may be protected from the consequences of unauthorized use. Partially or totally publication of an article elsewhere is possible only after the consent from the editors.

References

Abdullah MMA, Hussin K, Bnhussain M, Ismail KN, Ibrahim WMW. Mechanism and chemical reaction of fly ash geopolymer cement-a review. International Journal of Pure and Applied Sciences and Technology 2011;6(1):35-44.

Al-Zboon K, Tahat M, Abu-Hamatteh ZSH, Al-Harahsheh MS. Recycling of stone cutting sludge in formulations of bricks and terrazzo tiles. Waste Management and Research 2010;28(6):568-74.

Andreola F, Barbieri L, Lancellotti I, Leonelli C, Manfredini T. Recycling of industrial wastes in ceramic manufacturing: State of art and glass case studies. Ceramics International 2016;42(12):13333-8.

American Public Health Association (APHA). Standard Methods for the Examination of Water and Wastewater. Washington, DC, USA: American Public Health Association; 2012.

Ashfaq M, Moghal AAB. Cost and carbon footprint analysis of flyash utilization in Earthworks. International Journal of Geosynthetics and Ground Engineering 2022;8(2):Article No. 21.

Behera SK, Mishra DP, Singh P, Mishra K, Mandal SK, Ghosh CN, et al. Utilization of mill tailings, fly ash and slag as mine paste backfill material: Review and future perspective. Construction and Building Materials 2021;309:Article No. 125120.

Brännvall E, Kumpiene J. Fly ash in landfill top covers: A review. Environmental Science: Processes and Impacts 2016; 18(1):11-21.

Center for Statistics and Science and Technology Information, Department of Science and Technology (CESTI-DOST). The Trend of Using Thermal Ash and Slag in the Production of Construction Materials. Vietnam: Center for Statistics and Science and Technology Information, Department of Science and Technology of Ho Chi Minh City; 2019.

de Sensale GR. Strength development of concrete with rice-husk ash. Cement and Concrete Composites 2006;28(2):158-60.

Dharek MS, Sreekeshava K, Vengala J, Pramod K, Sunagar P, Shivaprakash M. Experimental investigations on utilization of bagasse ash in adobe bricks. Select Proceedings of the International Conference on Civil Engineering Trends and Challenges for Sustainability (CTCS 2020); 2020 Dec 22-23; Karkala: India; 2020.

Giaccio G, de Sensale GR, Zerbino R. Failure mechanism of normal and high-strength concrete with rice-husk ash. Cement and Concrete Composites 2007;29(7):566-74.

General Statistics Office of Vietnam (GSOV). Report on agricultural, forestry and fishery production in 2022. Vietnam: General Statistics Office of Vietnam; 2022.

Hossain Z, Islam KT. Prospects of Rice Husk Ash as a Construction Material. Elsevier; 2022.

Huynh TP, Phan HP, Pham VH, Ngo VA, Luu HT. Utilization of waste incineration bottom ash as fine aggregate in the production of terrazzo tiles for pavement. Proceedings of the 2nd International Conference on Sustainable Civil Engineering and Architecture (ICSCEA 2021); 2021 Oct 30; Ho Chi Minh City: Vietnam; 2021.

Le TH, Park DW, Park JY, Phan TM. Evaluation of the effect of fly ash and slag on the properties of cement asphalt mortar. Advances in Materials Science and Engineering 2019; 2019(1):Article No. 1829328.

Li M, Zhang J, Li A, Zhou N. Reutilisation of coal gangue and fly ash as underground backfill materials for surface subsidence control. Journal of Cleaner Production 2020;254:Article No. 120113.

Ling I, Teo D. Reuse of waste rice husk ash and expanded polystyrene beads as an alternative raw material in lightweight concrete bricks. International Journal of Chemical and Environmental Engineering 2011;2(5):328-32.

Ministry of Construction (MOC). Vietnam National Standard of Terrazzo Bricks TCVN 7744-2013. Vietnam: Ministry of Construction; 2016.

Ministry of Construction (MOC). Instructions on Using Ash and Slag of Formosa Thermal Power Plant on the Market and Putting it into Use as Raw Materials for the Production of Building Materials - CV 916/BXD-VLXD. Vietnam: Ministry of Construction; 2017.

Mohajerani A, Lound S, Liassos G, Kurmus H, Ukwatta A, Nazari M. Physical, mechanical and chemical properties of biosolids and raw brown coal fly ash, and their combination for road structural fill applications. Journal of Cleaner Production 2017;166:1-11.

Nguyen, Lam VT, Ngo HX, Van P, Dang CA H, Vu DK. Effect of fly ash on the strength of cement paste at early age. Journal of Mining and Earth Sciences 2020;61(6):10-8.

Oner A, Akyuz S, Yildiz R. An experimental study on strength development of concrete containing fly ash and optimum usage of fly ash in concrete. Cement and Concrete Research 2005;35(6):1165-71.

Pant A, Ramana G, Datta M, Gupta SK. Coal combustion residue as structural fill material for reinforced soil structures. Journal of Cleaner Production 2019;232:417-26.

Peng G, Yang J. Influence of rice husk ash on the properties of concrete: A review. 2016 International Forum on Energy, Environment and Sustainable Development, Atlantis Press; 2016.

Phuong T, Hien T. Experimental study on manufacturing of adobe bricks from slag and fly ash of Nghi Son thermal power plant. Vietnam Environment Administration Magazine 2021;4:39-41.

Shaikh J, Bordoloi S, Leung AK, Yamsani SK, Sekharan S, Rakesh RR. Seepage characteristics of three-layered landfill cover system constituting fly-ash under extreme ponding condition. Science of the Total Environment 2021;758:Article No. 143683.

Talsania S, Pitroda J, Vyas CM. Effect of rice husk ash on properties of pervious concrete. International Journal of Advanced Engineering Research and Studies 2015;296:Article No. 299.

Teixeira ER, Camões A, Branco F. Valorisation of wood fly ash on concrete. Resources, Conservation and Recycling 2019;145:292-310.

Trang NTM, Ho NAD, Babel S. Reuse of waste sludge from water treatment plants and fly ash for manufacturing of adobe bricks. Chemosphere 2021;284:Article No. 131367.

Truong DN. Ash and ash use of coal-fired power plants. Proceedings of the Workshop on Environmental Protection in Mining, Processing and Use of Coal, Minerals and Petroleum; 2019 Aug 10; Khanh Hoa: Vietnam; 2019.

Vietnam Assemmbly (VNA). Law on Environmental Protection. Vietnam: The National Assembly of the Socialist Republic of Vietnam; 2020.

Zhang Zh, Yao X, Zhu Hj, Hua Sd, Chen Y. Preparation and mechanical properties of polypropylene fiber reinforced calcined kaolin-fly ash based geopolymer. Journal of Central South University of Technology 2009;16(1):49-52.