The Effect of Chemical Composition and Boiling Time in Kraft Method on Paper Making Based on Palm Oil Trunk (Elaeis guineensis Jacq.) 10.32526/ennrj/23/20250004

Main Article Content

Abstract

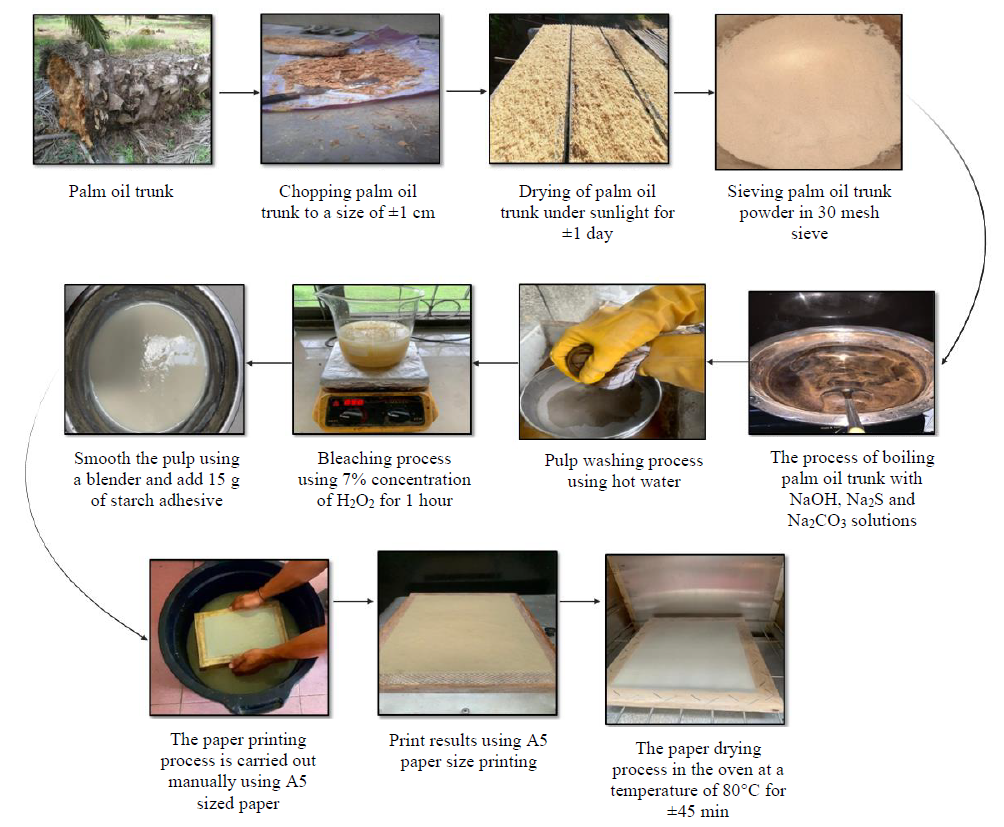

The rapid expansion of palm oil plantations in Indonesia generates significant waste, including an estimated 77.692 tons/ha of palm oil trunks. It is essential to recycling these trunks into valuable raw materials. Given their high cellulose content, palm oil trunks are promising for paper production. This study investigates the production of paper from palm oil trunks (Elaeis guineensis Jacq.) using the kraft process with variations in chemical composition and boiling time. Three chemical compositions are tested, involving sodium hydroxide (NaOH), sodium sulfate (Na2SO4), and sodium carbonate (Na2CO3), along with boiling times of 90, 120, and 150 min. Paper quality are analyzed through water absorption, tensile strength, grammage, and visual appearance. The optimal kraft method for water absorption and tensile strength involves a 120-minute boiling time and a chemical composition of 20% NaOH, 9% Na2S, and 4% Na2CO3, resulting in a water absorption of 59.33 mm, tensile strength of 11.26 kN/m, and a grammage of 65 g/m². Additionally, the clean, hole-free surface of the best-performing paper further validates the method's effectiveness. This study demonstrates that high-quality paper can be produce from palm oil trunks using optimal kraft process parameters, supporting sustainable waste utilization.

Article Details

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.

Published articles are under the copyright of the Environment and Natural Resources Journal effective when the article is accepted for publication thus granting Environment and Natural Resources Journal all rights for the work so that both parties may be protected from the consequences of unauthorized use. Partially or totally publication of an article elsewhere is possible only after the consent from the editors.

References

Abdelatif Y, Gaber A-AM, Fouda AE-AS, Elsokkary T. Sustainable utilization of calcined sugarcane mud waste as nanofiller for fine paper production. Biomass Conversion and Biorefinery 2024;14(7):8947-56.

Amon AS, Soro RY, Assemand EF, Dué EA, Kouamé LP. Effect of boiling time on chemical composition and physico-functional properties of flours from taro (Colocasia esculenta cv fouê) corm grown in Côte d’Ivoire. Journal of Food Science and Technology 2014;51(5):855-64.

Ayundra SD, Suwandi S, Herlinda S, Hamidson H, Wandri R, Asmono D. Soil physicochemical properties in respect to plant health in Ganodermainfested oil palm plantation. Journal of Scientific Agriculture 2022;6(1):9-13.

Castelló ML, Sesé T, García-Mares FJ, Juan-Borrás M del S, Ortolá MD. Influence of boiling time on chemical composition and properties of tender and mature Moringa pods. Foods 2024;13(12):Article No. 1823.

Coura MR, Demuner AJ, Demuner IF, Blank DE, Firmino MJM, Gomes FJB, et al. Technical kraft lignin from coffee parchment. Nordic Pulp and Paper Research Journal 2023;38(2):229-41.

Ek M, Gellerstedt G, Henriksson G. Paper Chemistry and Technology. Berlin, Germany: Walter de Gruyter; 2009.

Faris AH, Rahim A, Ibrahim MM, Hussin M, Alkurdi AM, Salehabadi A. Investigation of oil palm based Kraft and auto-catalyzed organosolv lignin susceptibility as a green wood adhesives. International Journal of Adhesion and Adhesives 2017;74(1):115-22.

Fenny FO, Farma W. The effect of the weight ratio of banana peel to newspaper and corn stalk to newspaper on the tensile index and tear index of recycled paper. Prosiding Semnastek 2016;2016(TK-011):1-7.

Ferdous T, Quaiyyum MA, Jin Y, Bashar MS, Yasin Arafat KM, Jahan MS. Pulping and bleaching potential of banana pseudo stem, banana leaf and banana peduncle. Biomass Conversion and Biorefinery 2021;13(1):893-904.

Ghahri S, Park B-D. Ether bond formation in waste biomass- derived, value-added technical hardwood kraft lignin using glycolic acid. Journal of Research Updates in Polymer Science 2023;12(1):171-9.

Gozan M, Abd-Aziz S, Jenol MA. Utilization of palm oil waste as a sustainable food resource. In: Bisaria V, editor. Handbook of Biorefinery Research and Technology: Production of Biofuels and Biochemicals. Singapre: Springer Nature; 2024. p. 573-92.

Hailemariam TT, Woldeyes B. Production and characterization of pulp and paper from flax straw. Scientific Reports 2024;14(1): Article No. 24300.

International Organization for Standardization (ISO). ISO 1924-2:2008 Paper and Board-Determination of Tensile Properties- Part 2: Constant Rate of Elongation Method (20 mm/min). Geneva, Switzerland: International Organization for Standardization; 2008.

International Organization for Standardization (ISO). ISO 535:2014(E) Paper and Board-Determination of Water Absorptiveness-Cobb Method. Geneva, Switzerland: International Organization for Standardization; 2014.

International Organization for Standardization (ISO). ISO 536:2019(E) Paper and Board-Determination of Grammage. Geneva, Switzerland: International Organization for Standardization; 2019.

Itamiya H, Sugita R. Effects of printing and ninhydrin treatment on forensic analysis of paper. Forensic Science International 2015;255(1):38-42.

Joseph N, Kassim MHM, Ibrahim M, Rawi NFM, Sudesh K, Arai T, et al. The effects of autohydrolysis pretreatment on the properties of opt pulps for the production of dissolving pulp. Pertanika Journal of Science and Technology 2024;32(S3):27-39.

Kaima J, Preechawuttipong I, Peyroux R, Jongchansitto P, Kaima T. Experimental investigation of alkaline treatment processes (NaOH, KOH and ash) on tensile strength of the bamboo fiber bundle. Results in Engineering 2023;18:Article No. 101186.

Lau GW, King PJH, Chubo JK, King IC, Ong KH, Ismail Z, et al. The potential benefits of palm oil waste-derived compost in embracing the circular economy. Agronomy 2024; 14(11):Article No. 2517.

Liu Y, Ding Y, Li Y, Wang X, Sun Y, Chen C. A comprehensive review of recent advances in delignification technology. The Journal of The Textile Institute 2024;115(12):2489-504.

Low LQ, Ilyas RA, Jalil R, Hawanis HSN, Ibrahim R, Azriena HAA, et al. Physical and mechanical properties enhancement of beaten oil palm trunk pulp and paper by optimizing starch addition: Towards sustainable packaging solutions. Industrial Crops and Products 2024;221(1):Article No. 119232.

Lu Z, Zhang H, Liu L, Cao H, Cheng Z, Liu H, et al. Study on cellulose nanofibers (CNF) distribution behaviors and their roles in improving paper property. Industrial Crops and Products 2023;201(1):Article No. 116897.

Michael, Fath MT Al, Alexander V, Hasibuan GCR, Syukri M, Ginting MHS, et al. MATLAB-empowered brightness defect prediction system in pulp processing bleaching stage: An empirical modelling approach. Case Studies in Chemical and Environmental Engineering 2024;10:Article No. 100934.

National Standardization Agency (BSN). SNI 14-4737-1998: Test Method: Tensile Strength of Paper and Cardboard. Jakarta, Indonesia: National Standardization Agency; 1998.

National Standardization Agency (BSN). 7274 Standar Nasional Indonesia Printing Paper Grade A. Jakarta, Indonesia: Standar Nasional Indonesia (SNI); 2008.

Nova S. Pre-Design of Pulp Making Plant from Agar-Agar Waste with Production Capacity of 28,900 Ton/Year (Pra Rancangan Pabrik Pembuatan Pulp dari Limbah Agar-Agar dengan Kapasitas Produksi 28.900 Ton/Tahun) [dissertation]. Medan, Universitas Sumatera Utara; 2011 (in Indonesian).

Pulungan IT. Comparison Test of Recycled Paper Composition Based on Organic and Inorganic Waste [dissertation]. Medan, Universitas Sumatera Utara; 2017.

Putra SE, Dewata I, Barlian E, Syah N, Iswandi U, Gusman M, et al. Analysis of palm oil mill effluent quality. E3S Web of Conferences 2024;481:Article No. 03001.

Qiao C, Gong Y, Gong D. Distribution of in-plane physical properties of handmade Xuan paper: Revealing the effects of the sheet forming process and the folded state on handmade Xuan paper. Studies in Conservation 2023;69(1):35-49.

Ramadhani RP. Effect of Cooking Time and Sodium Hydroxide Concentration on Reducing Lignin Content of Corn Husk Pulp Using the Kraft Process [dissertation]. Surakarta, Universitas Muhammadiyah Surakarta; 2019.

Sahan Y, Rahmi SW, Herman S, Ohi H, Amri A. Enhancing dissolving pulp quality of mixed raw materials through pre-hydrolysis kraft-cooking: A study on Acacia crassicarpa and Terminalia catappa. Communications in Science and Technology 2024;9(2):372-8.

Senthilkumar ER, Sjöström J, Henriksson G, Vikström T, Sevastyanova O. Effect of storage conditions on the brownstock washing and oxygen delignification of kraft pulps. Cellulose 2025;32(1):2567-79.

Sharma A, Takanohashi T, Aizawa S, Kitao M, Anraku D. Effect of carbonization heating rate on the tensile strength of cokes prepared from chemically upgraded low rank coals. Iron and Steel Institute of Japan International 2019;59(8):1482-7.

Silva TCF, Gomide JL, Santos RB. Evaluation of chemical composition and lignin. BioResources 2012;7(3):3910-20.

Siti FMN, Dilaeleyana ABS, Aida M. Screening physical factors to enhance bioethanol production in oil palm trunk sap fermentation. Malaysian Journal of Analytical Sciences 2024;28(4):828-42.

Syamsu K, Puspitasari R, Roliadi H. Use of microbial cellulose from nata de cassava and coconut fiber as a substitute for wood cellulose in paper making. Jurnal Agroindustri indonesia 2012;1(2):118-24 (in Indonesian).

Tarigan FG. Determination of cellulose and lignin content of oil palm empty fruit bunch fiber through pulp making using soda process based on heating time. Jurnal Pembangunan Wilayah and Kota 2017;1(3):82-91 (in Indonesian).

Vachlepi A. Prospects for utilizing rubber wood as raw material for pulp making. Warta Perkaretan 2019;1(1):47-60 (in Indonesian).

Veronika N, Dhora A, Wahyuni S. Processing of palm oil waste into compost fertilizer using local microorganism decomposers (Mol) banana stems. Jurnal Teknologi Industri Pertanian 2019;29(2):154-61 (in Indonesian).

Wistara NJ, Rohmatullah MA, Febrianto F, Pari G, Lee S-H, Kim N-H. Effect of bark content and densification temperature on the properties of oil palm trunk-based pellets. Journal of the Korean Wood Science and Technology 2017;45(6):671-81.

Yennam R, Shivde P, Daware G, Mane V, Mawal V, Derle S. Synthesis of handmade craft-paper from agricultural waste. Indian Journal of Chemical Technology 2024;31(4):546-52.

Zakaria MA, Soh NMZN. The physical and mechanical properties of oil palm empty fruit bunch fibre (OPEFB) based on various fibre-cement ratios. Recent Trends in Civil Engineering and Built Environment 2023;4(3):428-38.