Applying Multi-Criteria Approaches to the Weld Bead Geometry Problem in Laser Welding With Filler Wire Process Using the Al-Mg-Mn-Zr-Er Alloy Sheet

doi: 10.14456/mijet.2022.19

Keywords:

Laser welding, selection, process parameters, multicriteria analysisAbstract

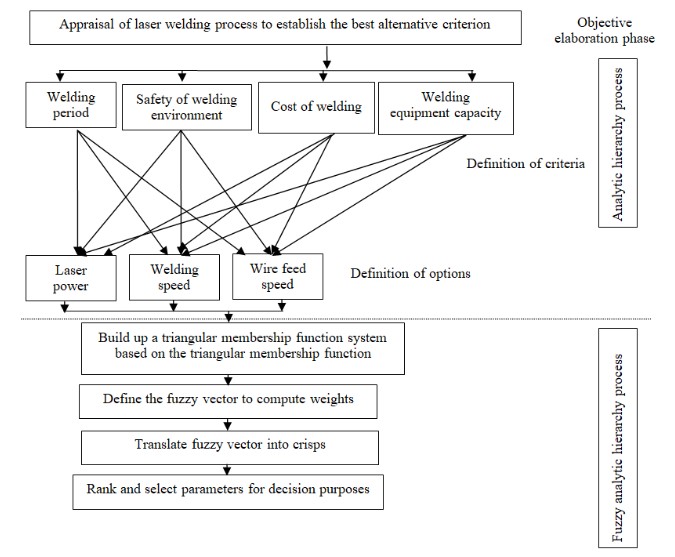

Al-Mg-Mn-Zr-Er alloy sheet is a prominent industrial material used by the automotive and aerospace industries. Yet little is known about which parameters substantially affect the weld bead geometry in laser welding. This article establishes the most influential process parameters in laser welding with filler wire process on the Al-Mg-Mn-Zr-Er alloy sheets focusing on laser power, welding speed, wire feed speed parameters. The data obtained from a paper was used for analysis. Five methods were compared, namely analytic hierarchy process (AHP) method, fuzzy analytic hierarchy process (FAHP) method, best-worst method, entropy method and criteria importance through inter-criteria correlation (CRITIC) method. The arithmetic mean (AM) method and the root mean square (RMS) method were used to compare the results of the five methods. Using the AM method, the FAHP method is the best (AM, 0.3367), the entropy method is the second position (AM, 0.3337) and the three methods of AHP, best worst and CRITIC (AM, 0.3333 each) were placed in the third position. Besides, for the RMS method, the entropy and FAHP methods were the first and second positions with the RMS values of 0.2094 and 0.1954, respectively. The third to the last positions were allocated to best worst (RMS, 0.1948), AHP (RMS, 0.1894) and CRITIC (RMS, 0.1274), respectively. Consequently, the FAHP method is the best and recommended to develop cost reduction strategies in the workshop. The novelty of this article is the application of five multicriteria methods, namely AHP, FAHP, best-worst, entropy and CRITIC to the Al-Mg-Mn-Zr-Er alloy sheets.

References

AWS C7.41C7.4M: 2017, "An American National Standard, process specification and operator qualification for laser beam welding," American Welding Society, 2nd Edition, June 27, 2017, Prepared by the American Welding Society (AWS) C7 committee on high Energy Beam Welding and cutting, AWS Technical Activities Committee.

D. A. Jennings, E. D. West, K. M. Evenson, A. L. Rasmussen, and W. R. Simmons, "Technical Note 382, Laser Power and Energy Measurements," United State Department of Commerce, National Bureau of Standards, pp. 1-64, 1969.

Industry Research, "2021-2027 Global and regional laser welding and cutting robots industry status and prospects," Professional Market Research Report Standard Version, SKU ID: HNY-18831957, 154p, 2021.

T. Webber, T. Lei, J. Mazumder, L. B. Welding, T. In Lienert, T. Siewert, S. Babu and V. Acoff (Eds), "ASM Handbook, Welding Fundamentals and Processes," ASM International (Volume 6A), Almere, the Netherlands. DOI: https://doi.org/10.31399/asm.hb.v06a.a0005641, 2011.

S. Katayama, "Handbook of Laser Welding Technologies, Woodhead Publishing," Cambridge, England, 2013.

W. M. Steen, J. Mazumder, "Laser Material Processing, SpringerLink. New York, USA, doi:10.1007/978-1-84996-062-5. ISBN 978-1-84996-061-8, 2010.

M. Kurtulmus, A. I. Yukler, M. K. Bilici, Z. Catalgol, "Effects of welding current and arc voltage on FCAW weld bead geometry," International Journal of Research in Engineering and Technology, vol. 4, no. 9, pp. 23-28, 2015.

D. Yang, X. Li, D. He, Z. Nie, H. Huang, "Optimization of weld bead geometry in laser welding with filler wire process using Taguchi’s approach, " Optics & Laser Technology, vol. 44, no. 7, pp. 2020-2025, 2012.

L. Bidi, P. Le Masson, E. Cicala, C. Primault, "Experimental design method to the weld bead geometry optimisation for hybrid laser-MAG welding in a narrow chamfer configuration," Optics and Laser Technology, vol.89, pp. 114-125, 2017.

B. Choudhury and M. Chandrasekaran, "Multi-optimization of weld bead characteristics during GTAW of Inconel 825 using teaching learning based optimization," Materials Today: Proceedings, vol. 46, no. 18, pp. 8958-8963, 2021.

X. Dong, G. Wang and M. Ghaderi, "Experimental investigation of the effects of laser parameters on the weld bead shape and temperature distribution during dissimilar laser welding of stainless steel 308 and carbon steel St 37," Infrared Physics and Technology, vol. 116, Article 103774. doi:10.1016/j.infrared.2021, 103774, 2021.

C. M. Horvath, J. Botzheima, T. Thomessen, P. Korondia, "Bead geometry modeling on uneven base metal surface by fuzzy systems for multi-pass welding," Expert Systems with Applications, Doi:10,1016/j.eswa.2021.115356, 2021.

S. F. Nabavi, M. H. Farshidianfar, A. Farshidianfar, B. Beidokhti, "Physical-based methodology for prediction of weld bead characteristics in the Laser Edge Welding process," Optik, vol.241,Article166917.https://doi.org/10.1016/j.ijleo.2021.166917, 2021.

W. Tayier, S. Janasekaran and V. P. Vijayasree, "Evaluation of heat input and bead geometry of zincalume steel (G550) welded joint between metal inert gas (MIG) and laser beam welding (LBW)," Materials Today: Proceedings, doi: 10.1016/j.matpr. 2021.02.494, 2021.

X. Wei, H. Huang, Z. Chen, W. Wang, C. Li, Z. Nie, "Microstructure and mechanical properties of Al-Mg-Mn-Zr-Er weld joints filled with Al-Mg-Mn-Zr and Al-Mg-Mn-Zr-Er weld wires," Journal of Rare Earths, vol. 28, no. 4, pp. 627-630. https://doi.org/10.1016/S1002-0721(09)60168-X, 2010.

D. Yang, X. Li, D. He, H. Huang and L. Zhang, "Study on microstructure and mechanical properties of Al–Mg–Mn–Er alloy joints welded by TIG and laser beam," Materials & Design, vol. 40, pp. 117-123, https://doi.org/10.1016/j.matdes.2012.03.041, 2012.

D. Yang, X. Li, D. He and H. Huang, 2013, "Effect of minor Er and Zr on microstructure and mechanical properties of Al–Mg–Mn alloy (5083) welded joints," Materials Science and Engineering: A, vol. 561, pp. 226-231. https://doi.org/10.1016/j.msea.2012.11.002, 2013.

X. Lei, H. Huang and H. Wang, "The fatigue crack propagation of Al-Mg-Mn-Zr alloy with erbium," Advanced Materials Research, vol. 1120-1121, pp. 1083-1088, 2015.

H. Wu, S. P. Wen, H. Huang, X. L. Wu, K. Y. Gao, W. Wang and Z. R. Nie, "Hot deformation behavior and constitutive equation of a new type Al–Zn–Mg–Er–Zr alloy during isothermal compression," Materials Science and Engineering: A, vol. 651, pp. 415-424. https://doi.org/10.1016/j.msea.2015.10.122, 2016.

H. Wu, S. P. Wen, H. Huang, K. Y. Gao, X. L. Wu, W. Wang and Z. R. Nie, "Hot deformation behavior and processing map of a new type Al-Zn-Mg-Er-Zr alloy," Journal of Alloys and Compounds, vol. 685, pp. 869-880. https://doi.org/10.1016/j.jallcom.2016.06.254, 2016.

D. Wu, N. Wang, Z. Yang, C. Li, Y. Yang, "Comprehensive evaluation of coal-fired power units using grey relational analysis and a hybrid entropy-based weighting method," Entropy, vol. 20, pp.215, 2018.

D. Yang, X. Li, D. He, Z. R. Nie and H. Huang, "Microstructural and mechanical property characterization of Er modified Al–Mg–Mn alloy tungsten inert gas welds," Materials & Design, vol. 34, pp. 655-659. https://doi.org/10.1016/j.matdes.2011.05.022, 2012.

Z. Zhang, S. Dong, Y. Wang, B. Zu, J. Fang and P. He, "Microstructure characteristics of thick aluminum alloy plate joints welded by fiber laser," Materials & Design, vol. 84, pp. 173-177, DOI:10.1016/j.matdes.2015.06.08, 2015.

H. Wu, S. P. Wen, H. Huang, B. L. Li, X. L. Wu, K. Y. Gao, W. Wang and Z. R. Nie, "Effects of homogenization on precipitation of Al3(Er,Zr) particles and recrystallization behavior in a new type Al-Zn-Mg-Er-Zr alloy," Materials Science and Engineering: A, vol. 689, pp. 313-322. https://doi.org/10.1016/j.msea.2017.02.071, 2017.

A. P. Aravind, J. S. Kurmi, P. M. Swamy, S. R. Kumar, S. Rajak and T. D. B. Kannah, "Optimisation of welding parameters in laser welding of Ti6Al4V using VIKOR optimisation method," Materials Today: Proceedings, vol. 45, no. 2, pp. 592-596, doi:10.1016/j.matpr.2020.02.388, 2021.

M. S. Khan, S. I. Shahabad, M. Yavuz, W. W. Duley, E. B. Y. Zhou, "Numerical modelling and experimental validation of the effect of laser beam defocusing on process optimisation during fiber laser welding of automotive press-hardened steels," Journal of Manufacturing Process, vol 67, pp. 535-544. DOI:10.1016/j.jmapro.2021.05.006, 2021.

Y. Huang, X. Gao, B. Ma, G. Lui, N. Zhang, Y. Zhang, D. You, "Optimisation of weld strength for laser welding of steel to PMMA using Taguchi design method," Optics and Laser Technology, vol. 136, Article 106726, doi:10.1016/j.optlastec.2020.106726, 2021.

M. Hietala, M. Ali, A. Khosravifard, M. Keskitala, A. Jarvenpaa and A. Hamda, "Optimisation of the tensile shear strength of laser-welded lap joints of ultra-high strength abrasion resistance steel," Journal of Material Research and Technology, vol. 11, pp. 1434-1442, doi:10.1016/j.jmrt.2021.01.121, 2021.

T. D. B. Kannan, A. P. Aravind, P. Sathiya, "Experimental investigation and optimisation of process parameters in laser welding of Nitinol shape memory alloys," Materials Today: Proceedings, vol. 22, no. 4, pp. 1563-1571, doi:10.1016/j.matpr.2020.02.118, 2020.

S. Datta, M. S. Raza, A. K. Das, P. Saha, D. K. Pratihar, "Experimental investigations and parametric optimization of laser beam welding of NiTinol sheets by metaheuristic techniques and desirability function analysis," Optics and Laser Technology, vol. 124, Article 105982, doi: 10.1016/j.optlastec.2019.105982, 2020.

Z. Lei, J. Shen, Q. Wang, Y. Chen, "Real-time weld geometry prediction based on multi-information using neural network optimized by PCA and GA during thin-plate laser welding," Journal of Manufacturing Processes, vol. 43, no. 10, pp. 207-217. DOI: 10.1016/j.jmapro.2019.05.013, 2019.

K. R. Sampreet, V. Mahidhar, R. Kannan, Arunagiri and T. D. B. "Optimization of parameters in Nd:YAG laser welding of Ti-6Al-4V using TOPSIS, Materials Today: Proceedings," vol. 21, no. 1, pp. 244-247, https://doi.org/10.1016/j.matpr.2019.05.401, 2020.

Y. Yang, Z. Gao and L. Cao, "Identifying optimal process parameters in deep penetration laser welding by adopting Hierarchical-Kriging model," Infrared Physics and Technology, vol. 92, pp. 443-453, doi: 10.1016/j.infrared.2018.07.006, 2018.

U. Reisgen, M. Schleser, O. Mokrov, E. Ahmed, "Optimization of laser welding of DP/TRIP steel sheets using statistical approach," Optics and Laser Technology, vol. 44, no. 1, pp. 255-262, doi: 10.1016/j.optlastec.2011.06.028, 2012.

P. Zhang, Z. Jia, Z. Yu, H. Shi, S. Li, D. Wu, H. Yan, X. Ye, J. Chen, F. Wang and Y. Tian, "A review on the effect of laser pulse shaping on the microstructure and hot cracking behavior in the welding of alloys," Optics & Laser Technology, vol. 140, Article 107094, https://doi.org/10.1016/j.optlastec.2021.107094, 2021.

Y. Qu, Z. Li, J. Li, D. Zou, R. Zhang and Y. Yu, "Effect of weld geometry parameters on dynamic behavior of buried X70 steel pipeline under subsurface detonation," International Journal of Pressure Vessels and Piping, doi: 10.1016/j.ijpvp.2021.104504, 2021.

V. Paranthaman, D. Veeman and V. S. Mahesh, "Optimization of CO2 welding process on dissimilar metals," Materials Today: Proceedings, vol. 39, doi: 10.1016/j.matpr.2020.07.694, 2020.

S. Grünenwald, A. Unt and A. Salminen, "Investigation of the influence of welding parameters on the weld geometry when welding structural steel with an oscillated high-power laser beam," Procedia CIRP, vol. 74, pp.461-465, https://doi.org/10.1016/j.procir.2018.08.150, 2018.

C. Prieto, E. Vaamonde, D. Diego-Vallejo, J. Jimenez, B. Urbach, Y. Vidne and E. Shekel, "Dynamic laser beam shaping for laser aluminium welding in e-mobility applications," Procedia CIRP, vol. 94, pp. 596-600. https://doi.org/10.1016/j.procir.2020.09.084, 2020.

Z. Guo, R. Bai, Z. Lei, H. Jiang, J. Zou and C. Yan, "Experimental and numerical investigation on ultimate strength of laser-welded stiffened plates considering welding deformation and residual stresses," Ocean Engineering, vol. 234, Article 109239, https://doi.org/10.1016/j.oceaneng.2021.109239, 2021.

S. K. Gupta, S. Jaypuria, D. K. Pratihar, P. Saham, "Study on mechanical and metallurgical properties of fiber laser welded Nb-1% Zr-0.1% C alloy," Optics & Laser Technology, vol. 127, Article 106153, 2020.

S. M. Robertson and A. F. H. Kaplan "Multi-keyhole separation during multi-spot laser welding of duplex steel," Optics and Laser Technology, vol. 143, 2021.

P. M. Mashinini, D. G. Hattingh, "Influence of laser heat input on weld zone width and fatigue performance of Ti-6Al-4V sheet," Materials Science and Engineering B, vol. 262, Article 114699, doi: 10.1016/j.mseb.2020.114699, 2020.

V. Errico, S. L. Campanelli, A. Angelastro, M. Mazzarisi and G. Casalino, "On the feasibility of AISI 304 stainless steel laser welding with metal powder," Journal of Manufacturing Processes, vol. 56, pp. 96-105, https://doi.org/10.1016/j.jmapro.2020.04.065, 2020.

S. Liu, F. Liu, H. Zhang, Y. Shi, "Analysis of droplet transfer mode and forming process of weld bead in CO2 laser–MAG hybrid welding process," Optics & Laser Technology, vol. 44, no. 4, pp. 1019-1025. https://doi.org/10.1016/j.optlastec.2011.10.016, 2012.

T. Sathish, S. D. Kumar, K. Muthukumar and K. Suyambu K. "Natural inspiration technique for the parameter optimization of A-GTAW welding of naval steel," Materials Today: Proceedings, vol. 21, doi: 10.1016/j.matpr.2019.07.600, 2019.

X. Chen, G. Yu, X. He, S. Li and Z. Li, "Numerical study of heat transfer and solute distribution in hybrid laser-MIG welding," International Journal of Thermal Sciences, vol. 149, Article 106182. doi: 10.1016/j.ijthermalsci.2019.106182, 2020.

M. Şahin, "A comprehensive analysis of weighting and multicriteria methods in the context of sustainable energy," International Journal of Environmental Science and Technology, vol. 18, pp. 1591–1616, https://doi.org/10.1007/s13762-020-02922-7, 2021.

V. M. Ozernoy, "Choosing the “Best” multiple criteria decision-making method," Information Systems and Operational Research, vol. 30, pp. 159–171. https://doi.org/10.1080/03155986.1992.11732192, 1992.

A. Ishizaka, S. Siraj, "Are multi-criteria decision-making tools useful? An experimental comparative study of three methods," European Journal of Operational Research, vol. 264, pp. 462–471, https://doi.org/10.1016/j.ejor.2017.05.041, 2018.

M. Haddad and D. Sanders, "Selection of discrete multiple criteria decision making methods in the presence of risk and uncertainty," Operations Research Perspectives, vol. 5, pp. 357–370, https://doi.org/10.1016/j.orp.2018.10.003, 2018.

R. Mosadeghi, J. Warnken, R. Tomlinson, H. Mirfenderesk, "Uncertainty analysis in the application of multi-criteria decision-making methods in Australian strategic environmental decisions," Journal of Environmental Planning and Management, vol. 56, pp. 1097–1124, https://doi.org/10.1080/09640568.2012.717886, 2013.

I. Yukler and I. Calis, "Weld Bead Geometry," MUTEF Publications, İstanbul, 1999.

J. Matys, M. Dominiak and R. Flieger, "Energy and power density: A key factor in lasers studies," Journal of Clinical and Diagnostic Research, vol. 9, no. 12, pp. ZLO1-ZL02. doi: 10.7860/JCDR/2015/1556.6955, 2015.

R. Kant, S. N. Joshi and U. S. Dixit, "Research issues in the laser sheet bending process," in Materials Forming and Machining, pp. 73-97, doi: 10.1016/b978-0-8570-483-4.000041, 2016.

T. L. Saaty, "Decision making with the analytic hierarchy process," International Journal of Services Sciences, vol. 1, no. 1, pp. 83–98, 2008.

K. O. Okponyia and S. A. Oke, "Exploring aluminium alloy metal matrix composites in EDM using coupled factor-level-present worth analysis and fuzzy analytic hierarchy process," International Journal of Industrial Engineering and Engineering Management, vol. 2, no. 1, pp. 25-44, 2020.

M. Singh M. and R. Rathi, "Investigation on critical success factors associated with lean six sigma implementation in MSMEs using best-worst method," International Journal of Six Sigma and Competitive Advantage, vol. 12, no. 2/3, pp. 209-233. doi: 10.1504/IJSSCA. 2020. 110976, 2020.

V. Raghunathan, R. Ranganathan and M. Palamisamy, "An efficient supplier selection model for the pump industry through the best-worst method," International Journal of Services and Operations Management, vol. 28, no. 3, pp. 360-378. doi:10.1504/IJSONA2021.113601, 2021.

J. Liang, Z. D. Shi, M. J. Wierman, "Information entropy, rough entropy and knowledge granulation in incomplete information systems," International Journal of General Systems, vol. 35, pp. 641–654, 2006.

H. Zhao, L. Yao, G. Mei, T. Liu and Y. Ning, "A Fuzzy comprehensive evaluation method based on AHP and entropy for landslide susceptibility map," Entropy, vol. 19, pp. 396, 2017.

N. M. Raffic, K. G. Babu, S. Srinivasan, S. Thirumurugaveerakumar and R. B. Kanna, "Experimental investigation on surface roughness and cutting tool – Workpiece interface temperature for AA6061 using CRITIC and TOPSIS techniques," Materials Today: Proceedings, In press, https://doi.org/10.1016/j.matpr.2021.05.145, 2021.

X. Dong, H. Lu, Y. Xia, Z. Xiong, "Decision-making model under risk assessment based on entropy," Entropy, vol. 18, pp. 404, 2016.

Downloads

Published

How to Cite

Issue

Section

License

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.