Optimization of Wire Electrical Discharge Machining Process Parameters for Al7075/Al2O3/SiC Composite using Aspect Ratios of Taguchi Method, Taguchi-Pareto and Taguchi-ABC Methods

doi: 10.14456/mijet.2023.1

Keywords:

wire EDM, aspect ratios, optimisation, orthogonal array, factors, levelsAbstract

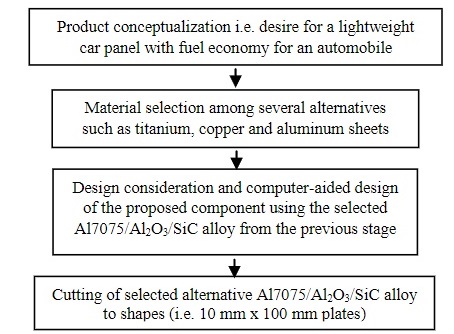

Aspect ratio determination has recently become a new way of evaluating the optimal parametric setting using the Taguchi method and following the orthogonal array-signal-to-noise ratio-response table route. Unfortunately in the machining domain, there is no account of any computations made using completely aspect ratios. But available records show a blend of direct and aspect ratios. To deviate from the extant literature practice, this article proposes a situation where all the factors are considered as aspect ratios for the determination of optimal process parameters in a wire electrical discharge machining process. Aspect ratios are integrated into the evaluation scheme at the factor-level stage where the ratios of each direct factor are obtained relative to the others. The values obtained are then transformed in an orthogonal matrix format to the signal-to-noise ratios, which are summarized as averages in the response table to obtain the optional parametric settings. The optimal parametric settings for the Taguchi method is (A/B)1(A/C)1(A/D)1which is interpreted as 2.00 for a pulse on-time/pulse off time, 2.00µѕ/A for a pulse on-time/current and 1.00µѕmin/ m for a pulse on-time/ wire drum speed. The ranks of the factors after the Taguchi analysis are A/C(pulse on-time/current) ranked 1st, A/B (pulse on-time/pulse off time) ranked 2nd and A/D (pulse on-time/ wire drum speed) ranked 3rd. Furthermore, the optimal parametric settings using Taguchi Pareto’s method is (A/B)1(A/C)1(A/D)1which is interpreted as 2.00 for a pulse on-time/pulse off time, 2.00µѕ/A for a pulse on-time/current and 1.00µѕmin/ m for a pulse on-time/ wire drum speed. The ranks of the factors after Taguchi-Pareto analysis are A/D (pulse on-time/ wire drum speed) ranked 1st, A/C (pulse on-time/current) ranked 2nd and A/B (pulse on-time/pulse off time) ranked 3rd. Now, focusing on the results of group A alone in the Taguchi-ABC method, the optimal parametric settings for group A are (A/B)1 (A/C)1(A/D)1 which is interpreted as 2.00 for pulse on-time/pulse off time, 2.00 µѕ/A for a pulse on-time/current and 1.00 µѕ min/m for a pulse on-time/ wire drum speed. The ranks of the factors after Taguchi ABC analysis for Group A are A/C(pulse on-time/current) ranked 1st, A/B (pulse on-time/pulse off time) ranked 2nd and A/D (pulse on-time/ wire drum speed) ranked 3rd. The synergy between the aspect ratios and the orthogonal arrays helps the process engineers/operators of wire. EDM machines practically and effectively optimize the process and select the most promising aspect ratios and values for further decisions. The aspect ratios respond to the methods and offer the first step towards attaining a sustainable wire EDM process.

References

J.E.A. Qudeiri, A. Zaiout, A.I. Mourad, M.H. Abidi and A. Elkaseer "Principles and characteristics of different EDM processes in machining tool and die steels", Applied Sciences, vol. 10, no.6, 2082, 2020. https://doi.org/10.3390/app10062082

A. Kumar, S. Kumar, N.K. Mukhopadhyay “Introduction to magnesium alloy processing technology and development of low-cost stir casting process for magnesium alloy and its composites”, Journal of Magnesium and Alloys, vol. 6, no. 3, 245-254, 2018a. https://doi.org/10.1016/j.jma.2018.05.006

W.J.Joost, P.E. Krajewski “Towards magnesium alloys for high-volume automotive applications”, Scripta Materialia, vol. 128, 107-112, 2017.

https://doi.org/10.1016/j.scriptamat.2016.07.035

M. Kiani, I. Gandikota, M. Rais-Rohani, K. Motoyama “Design of lightweight magnesium car body structure under crash and vibration constraints”, Journal of Magnesium and Alloys, vol.2, no.2, 99-108, 2014. https://doi.org/10.1016/j.jma.2014.05.005

A. Muniappan, M. Sriram, C. Thiagarajan, G.B. Raja & T. Shaafi “Optimization of WEDM process parameters on machining of AZ91 magnesium alloy using MOORA method”, IOP Conf. Series: Materials Science and Engineering, vol. 390, no. 1, 012107, 2018. https://doi.org/10.1088/1757-899X/390/1/012107

Y. Yuan, Q. Guo, J. Sun, H. Liu, Q. Xu, Y. Wu, D. Song, J. Jiang and A. Ma “High mechanical properties of AZ91 Mg alloy processed by equal channel angular pressing and rolling”, Metals, vol. 9, Article 386, 2019. https://doi.org/10.3390/met9040386

S. Lal, S. Kumar, Z.A. Khan, A.N. Siddiquee “Multi-response optimization of wire electrical discharge machining process parameters for Al7075/Al2O3SiC hybrid composite using Taguchi based grey relational analysis, Proceedings of IMechE Part B, Journal of Engineering Manufacture, vol. 229, no. 2, pp. 229-237, 2015. https//doi.org/10.117.7/0954405414526382

S. Suresh, G.H. Gowd and M.L.S. Devakumar “Corrosion behaviour of Al7075/Al2O3/SiC MMNCs by weight loss method”, Journal of Bio-and Tribo-Corrosion, Vol. 4, Article 62, 2018. https://doi.org/10.1007/s40735-018-0182-8

N. Raghavendra, V.S. Ramamurthy “Development and wear characterization of Al7075/Al2O3/SiC hybrid particulate metal matrix composite developed by stir casting”, International Journal of Research in Engineering and Technology, vol. 4, no. 8, pp. 16-21, 2015.

N. Sreedhar, 2021, Wear characteristics of Al7075/Al2O3/SiC hybrid metal matrix nanocomposites, Materials Science Forum, vol. 1034, pp. 43-49. https://doi.org/10.4028/www.scientific.net/MSF.1034.43

M.R. Kumar, H.N. Redduppa, R. Suresh “Mechanical and wear behaviour of Al7075/Al2O3/SiC hybrid composite”, Materials Today: Proceedings, vol 5, pp. 5573-5579, 2018b. https://doi.org/10.1016/j.matpr.2017.12.148

G.B.V. Kumar, C.S.P. Rao, N. Selvaraj, M.S. Bhagyashekar “Studies on Al6061-SiC and Al7075-Al2O3 metal matrix composites”, Journal of Minerals & Materials Characterization & Engineering, vol. 9, no.1, pp.43-55, 2010. https://doi.org/10.4236/jmmce.2010.91004

A.M. Rajesh, M. Kaleemulla, S. Doddamani, K.N. Bharath “Material characterization of SiC and Al2O3–reinforced hybrid aluminum metal matrix composites on wear behaviour”, Advanced Composites Letters, vol. 28, no. 6, 2019, 096369351985635. https://doi.org/10.1177/0963693519856356

R. Chalisgaonkar and J. Kumar “Process capability analysis and optimization in WEDM of commercially pure titanium”, Procedia Engineering, vol. 97, pp. 758–766, 2014. https://doi.org/10.1016/j.proeng.2014.12.306

B.B. Nayak, S.S. Mahapatra “A utility concept approach for multi-objective optimization of taper cutting operation using WEDM”, Procedia Engineering, vol. 97, pp. 469–478, 2014. https://doi.org/10.1016/j.proeng.2014.12.271

R. Chaudhari, S.Khanna, J.Vora,V.K. Patel, S. Paneliya, D.Y. Pimenov, K. Giasin, S. Wojciechowski "Experimental investigations and optimization of MWCNTs-mixed WEDM process parameters of nitinol shape memory alloy" Journal of Materials Research and Technology, vol. 15, pp. 2152-2169, 2021. https://doi.org/10.1016/J.JMRT.2021.09.03

S.A. Sonawane, M.L. Kulkarni “Optimization of machining parameters of WEDM for Nimonic-75 alloy using principal component analysis integrated with Taguchi method”, Journal of King Saud University, vol. 30, no. 3, pp. 250-258, 2018, http://dx.doi.org/10.1016/j.jksues.2018.04.001

X.L. Ai, G. Quan “Effect of Ti on the mechanical properties and corrosion of cast AZ91 magnesium alloy”, The Open Materials Science Journal, vol. 6, pp. 6-13, 2012.

S. Danthal, S.S. Rao, B.N. Rao, K. Mannepalli, Multi-objective optimization with modified Taguchi approach to specify optimal robot spray painting process parameters, International Journal of Nonlinear Analysis and Application, vol. 12, no. 2, pp. 1163-1174, 2021. http://dx.doi.org/10.22075/IJNAA.2021.5193

N. Harudin, K.R. Jamaludin, M.N. Muhtazaruddin, F. Ramlie, W.Z. Azman, W. Muhamad, N.N. Jaafar “Artificial bee colony for features selection optimization in increasing T-method accuracy”, International Journal of Engineering & Technology, vol. 7, pp. 885-891, 2018. https://doi.org/10.14419/ijet.v7i4.35.26276

R.B. Penteado, T.G. Hagui, J.C. Faria, M.B. Silva, M.V. Ribeiro “Application of Taguchi method in process improvement of turning of a superalloy nimonic 80A”, POMS Conference, Vancouver, BC, Canada, pp. 1-17, 2010.

A. Mishra and A. Gangele “Application of taguchi method in optimization of tool flank wear width in turning operation of AISI 1045 steel", Industrial Engineering Letters, vol. 2, no. 8, pp. 11-18, 2012.

S.J. Kast “Applying significance testing to the taguchi methods of quality control”, Ph.D. Thesis, Business Administration, Louisiana State University and Agriculture and Mechanical College, Louisiana LSU Historical Dissertations and Theses. 6427, 1997. https://digitalcommons.lsu.edu/gradschool_disstheses/6427

K. Krishnaiah and P. Shahabudeen “Applied Design of Experiments and Taguchi Methods”, PHI Learning Private Limited, New Delhi, India, 2012.

P.P. Das, P. Gupta, R.K. Ghadai, M. Ramachandran, K. Kalita “Optimization of turning process parameters by taguchi-based six sigma”, Mechanics and Mechanical Engineering, vol. 21, no. 3, pp. 649–656, 2017.

A. Rajesh, J. Venkatesh “Taguchi method and Pareto ANOVA: An approach for process parameters optimization in micro EDM drilling”, International Journal of Scientific and Engineering Research, vol. 5, no. 10, pp. 38-42, 2014.

O.A. Ajibade, J.O. Agunsoye, S.A. Oke “Taguchi method and taguchi-pareto scheme to evaluate diffusivity during the development of orange peel epoxy composites”, Journal of Applied Science & Process Engineering, vol. 8, no. 1, pp. 765-785, 2021. https://doi.org/10.33736/jaspe.3011.2021

S. Rao, P. Samant, A. Kadampatta, R. Shenoy “An overview of taguchi method: Evolution, concept and interdisciplinary applications”, International Journal of Scientific & Engineering Research, vol. 4, no. 10, 2013.

Z.A. Khan, A.N. Siddiquee, N.Z. Khan, U. Khan, G.A. Quadir “Multi response optimization of wire electrical discharge machining process parameters using Taguchi based grey relational analysis, Procedia Materials Science, vol. 6, pp. 1683-1695, 2014. https://doi.org/10.1016/j.mspro.2014.07.154

E. Galvan “Parametric optimization: Applications in systems design”, Ph.D. Thesis, Department of Mechanical Engineering, Texas A and M University, Texas, USA, 2016. https://hdl.handle.net/1969.1/158939.

G.H. Gowd, M.G. Reddy, B. Sreenivasulu, M. Ravuri “Multi objectives optimization of process parameters in WEDM during machining of SS304”, Procedia Materials Science, Vol. 5, pp. 1408-1416, 2014. https://doi.org/10.1016/j.mspro.2014.07.459

V. Singh, and S.K. Pradhan, 2014, Optimization of WEDM parameters using Taguchi technique and response surface methodology in machining of AISI D2 Steel, Procedia Engineering, vol. 97, pp. 1597–1608, 2014. https://doi.org/10.1016/j.proeng.2014.12.310

D. Sudhakara and G. Prasanthi “Application of taguchi method for determining optimum surface roughness in wire electric discharge machining of P/M cold worked tool steel (Vanadis-4E)”, Procedia Engineering, vol. 97, pp. 1565–1576, 2014. https://doi.org/10.1016/j.proeng.2014.12.440

J.B. Saedon, N. Jaafar, M.A. Yahaya, N.H. Saad and M.S. Kasim “Multi-objective optimization of titanium alloy through orthogonal array and grey relational analysis in WEDM”, Procedia Technology, Vol. 15, pp. 832–840, 2014. https://doi.org/10.1016/j.protcy.2014.09.057

C. Gao, Z. Zhan, S. Wang, N. He, L. Li “Research on WEDM process optimization for PCD micro milling tool”, Procedia CIRP, vol. 6, pp. 209–214, 2013. https://doi.org/10.1016/j.procir.2013.03.035

M. Schwade “Fundamental analysis of high frequent electrical process signals for advanced technology developments in W-EDM”, Procedia CIRP, vol. 14, pp. 436–441, 2014. https://doi.org/10.1016/j.procir.2014.03.007

R.M. Adegoke and S.A. Oke 2021, Optimizing turning parameters for the turning operations of Inconel X750 alloy with nanofluids using direct and aspect ratio-based Taguchi methods, International Journal of Industrial Engineering and Engineering Management, vol. 3, no. 2, pp. 59-76. https://doi.org/10.24002/ijieem.v3i2.5457.

S.A. Oke, A.A. Adekoya “Aspect ratio consideration in the optimisation of maintenance downtime for handling equipment in a container terminal”, Engineering Access, vol. 8, no. 1, pp. 129-141, 2022. https://doi.org/10.14456/mijet.2022.18

B.C. Oji and S.A. Oke 2020, Optimisation of bottling process using “hard” total quality management elements, The TQM Journal, vol. 33, no. 2, pp. 473-502, 2020. https://doi.org/10.1108/TQM-03-2020-0057

R. Karthigeyan “Characterization of mechanical properties of as-cast Al7075/basalt short fiber metal matrix composites and their effects under single and double stage forged conditions”, Ph.D., thesis, Faculty Mechanical Engineering, Anna University, Chennai, India, 2014.

S. Skolianos and T.Z. Kattamis, 1993, Tribological properties of SiCp reinforced Al-4.5% Cu-1.5% mg alloy composites, Material Science Engineering A, vol. 163, no. 1, pp. 107-113, 1993.

H. Akbulut, M. Durman and F. Yilmaz “Dry wear and friction properties of delta-Al2O3 short fiber reinforced Al-Si (LM13) alloy material metal matrix composites”, Wear, vol. 215, no. 1-2, pp. 170-179, 1998.

Downloads

Published

How to Cite

Issue

Section

License

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.