Application of Taguchi, Taguchi-Pareto and Taguchi-ABC Methods for the Selection and Optimization Problem in Friction Stir Welding Process Parameters of AA6062-T6 Alloy

doi: 10.14456/mijet.2022.32

Keywords:

Friction stir welding, optimisation, selection, orthogonal arrays, aluminium alloysAbstract

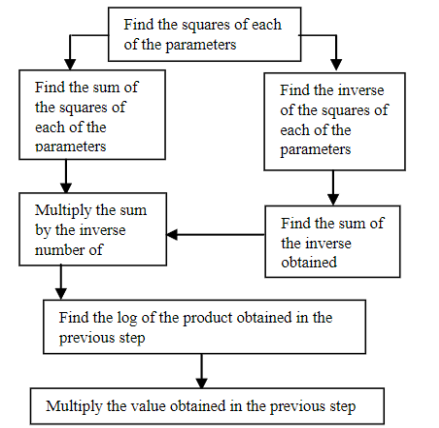

In sharing friction stir welding input resources before working, several conflicting demands are made by welders in the system. However, there is no mechanism to distinguish the importance of the respective parameters. This article proposes two novel methods of Taguchi-Pareto and Taguchi-ABC, to concurrently optimize and prioritize process parameters while understanding the importance of parameters in the welding decision process. The input parameters are tool tilt angle, tool rotational speed and welding speed while the output is the tensile strength of the AA6063-T6 alloy. The Khan's specimen data, obtained from the literature is tensile specimens with a dimension of 350mm x 75mm employed in a Batliboi 10 HP milling machine operating at 2000 rpm during the friction stir welding experiments. The joints were made of EN31 die steel. The factor-level table is first formed for the response table development. Furthermore, the Pareto and ABC classification schemes were used to define the cut off points to distinguish the essential experimental trials from the rest. The tensile strength of the friction stirs welded joints of AA6062-T6 alloy are principally affected by the parameters of welding speed, tool tilt angle and rotational speed to yield the most favourable tensile strength. Taguchi Pareto showed the tool rotational speed (1400 rpm), tool tilt angle (2.5°) and welding speed (80 mm/min) as the 1st, 2nd and 3rd parameters respectively. Taguchi's ABC method (Part A) showed a tie between the tool tilt angle (2.5°) and welding speed (80mm/min) while the tool rotational speed (700 rpm) was the third. It is preferable to adopt the Taguchi-ABC method, Part A as the most suitable method with the least energy requirements. Previous literature has explored the Taguchi method but the present research introduces the prioritization idea into the methods to help process engineers in planning welding activities.

References

M. Arab, M. Zemri, “Optimization of process parameters on friction stir welding of AA6082-T6 butt joints using Taguchi method,” Mechanics and Mechanical Engineering, vol. 22, no. 4, pp. 1371-1380, 2018. https://doi.org/10.2478/mme-2018-0107

T. Ganapathy, K. Lenin, K. Pannerselvam, “Process parameters optimization of friction stir welding in aluminium alloy 6063-T6 by Taguchi method,” Applied Mechanics and Materials, vol. 867, pp. 97-104, 2017. https://doi.org/10.4028/www.scientific.net/AMM.867.97

P.P. Kumar, S.A. Basha, S.S Kumar, “Optimization of friction stir welding process parameters of aluminium alloy AA7075-T6 using Taguchi method,” International Journal of Innovative Technology and Exploring Engineering, vol. 8, no.12, pp. 290-297, 2019.

A. Lakshminarayanan & V. Balasubramanian, “Process parameters optimization for friction stir welding of RDE-40 aluminium alloy using Taguchi technique,” Transactions of Nonferrous Metals Society of China, vol. 18, no. 3, pp. 548-554, 2008. https://doi.org/10.1016/s1003-6326(08)60096-5

M.A. Mohamed, Y.H. Manurung, M.R. Abdul Rahim, N. Muhammed, F.A. Ghazali 2014, “Optimization of friction stir welding parameters with simultaneous multiple response consideration using multi-objective Taguchi method,” Advanced Materials Research, vol. 974, pp. 408-412, 2014. https://doi.org/10.4028/www.scientific.net/AMR.974.408

W. Muhammad, W. Husain, A. Tauqir, A. Wadood 2020, “Optimization of friction stir welding parameters of AA 2014-T6 alloy using Taguchi statistical approach,” Journal of Welding and Joining, vol. 38, no. 5, pp. 493-501, 2020. https://doi.org/10.5781/JWJ.2020.38.5.9

A. Raweni, V. Majstorovic, A. Sedmak, S. Tadic, S. Kirin, “Optimization of AA5083 friction stir welding parameters using Taguchi method,” Tehnicki Vjesnik, vol. 25, no. 3, pp. 861-866, 2019. https://doi.org/10.17559/TV-20180123115758.

J. Singh, B. Singh, “Impact of tool shape and rotatory speed on tensile strength and microstructure of AA6105 friction stir welded joints through Taguchi method,” International Journal on Emerging Technologies, vol. 11, no. 4, pp. 6-16, 2020.

M.K. Kuletci, F. Mendi, I. Sewim, O. Bastruk, “Fracture toughness of friction stir welded joints of AlCu4SiMg aluminium alloy,” Metal, vol. 44, no. 3, pp. 209-213, 2005.

M. Raturi, A. Garg, A. Bhattacharya, “Tensile strength and failure of dissimilar friction stir welded joints between 6061-T6 and 2014-T6 aluminium alloys,” Procedia Structural Integrity, vol .17, pp 495-502, 2019. https://doi.org/10.1016/j.prostr.2019.08.065

K.T. Thilagham, S. Muthukumaran, “Process parameter optimization and characterization of friction welded advancing side AA6082-T6 with retreating side AA7075-T651,” Materials Today: Proceedings, vol. 27, no. 3, pp. 2260-2264, 2020. https://doi.org/10.1016/j.matpr.2019.09.108

R.K. Bhushan, D. Sharma 2019, “Optimization of friction stir welding parameters for maximum ultimate tensile strength of AA6082/SiC/10p composites,” Advanced Composites, vol. 28, pp. 1-7, 2019. https://doi.org/10.1177/0963693519867707

P. Singh, S.K. Gandhi, H. Shergill 2012, Comparative study of friction stir and TIG welding for aluminium 6063-T6, International Journal of Engineering Research and Technology, vol. 1, no. 10, 2012.

S. Gopi, K. Manonmani, “Study of friction stir welding parameters in convectional milling machine for 6082-T6 aluminium alloy,” Australian Journal of Mechanical Engineering, vol. 10, no. 2, pp. 129-140, 2012. https://doi.org/10.7158/M12-016.2012.10.2

A.K. Hussain, S.A.P. Quadri, “Evaluation of parameters of friction stir welding for aluminium AA6351 alloy,” International Journal of Engineering Science and Technology, Vol. 2, No. 10, pp. 5977-5984, 2010.

N. Khan “Optimization of friction stir welding of AA6062 T6 alloy,” Materials Today: Proceedings, vol. 29, no. 2, pp. 448-455, 2020. https://doi.org/10.1016/j.matpr.2020.07.298

M.A. Mohammed, Y.H. Manurung, “Effect of friction stir welding parameters on fatigue resistance, weld quality and mechanical properties of A16061-T651,” Journal of Mechanical Engineering, vol. s12, no.1, pp 83-99, 2017.

A. Pradeep, S. Muthukumaran, “An analysis to optimized the process parameters of friction stir welded low alloy steel plates,” International Journal of Engineering Science and Technology, vol.5, no.3, pp. 25-35, 2013. https://doi.org/10.4314/ijest.v5i3.3

P. Raja, S. Bojanampat, R. Karthikeyan, R. Ganithi, “Effect of rotational speed and welding speed on friction stir welding of AA1100 aluminium alloy,” IOP Conference Series: Materials Science and Engineering, vol. 346, Article 012060, 2018

A. Chandrashekar, B.S. Ajaykumar, H.N. Reddappa, “Effect of pin profile and process parameters on the properties of friction stir welded Al-Mg alloy,” Materials Today: Proceedings, vol. 5, no. 3, pp. 22283–22292, 2018. https://doi.org/10.1016/j.matpr.2018.06.594

K.A. Prabha, P.K. Putha, B.S. Prasad, “Effect of tool rotational speed on mechanical properties of aluminium alloy 5083 weldments in friction stir weldings,” Materials Today: Proceedings, vol. 5, no., 9, 18535-18543, 2018. https://doi.org/10.1016/j.matpr.2018.06.196

A. Goyal, R.K. Garg, “Modelling and optimization of friction stir welding parameters in joining 5086 H32 aluminium alloy,” Scientia Iranica, vol. 26, pp. 2407-2417, 2019. https://doi.org/10.24200/SCI.2018.5525.1325

K.J. Singh, R.S. Sidhu 2021, Analyzing of mechanical properties and microstructure of friction stir welded AZ31 magnesium alloy joint, Materials Today: Proceedings, https://doi.org/10.1016/j.matpr.2021.12.136.

S.R. Prasad, A. Kumar, C.S. Reddy, L.S. Raju, “Influence of tool shoulder geometry on microstructure and mechanical properties of friction stir welded 2014-T6 aluminium alloy,” Materials Today: Proceedings, vol. 4, no. 9, pp. 10207-10211, 2017. https://doi.org/10.1016/j.matpr.2017.06.349

U. Das, V. Toppo, “Effect of tool rotational speed on temperature and impact strength of friction stir welding joint of two dissimilar aluminium alloy,” Materials Today: Proceedings, vol.5, no.2, pp. 6170-6175, 2018. https://doi.org/10.1016/j.matpr.2017.12.223

H. Abd El-Hafez., A. El-Megharbel, “Friction stir welding of dissimilar aluminium alloys,” World Journal of Engineering and Technology, vol. 6, pp. 408-419, 2018. https://doi.org/10.4236/wjet.2018.62025

C. Devanathan, M. Chenthil, D. Prithiviraj, “Joining of dissimilar aluminium alloys using friction stir welding,” International Journal of Engineering Development and Research, vol. 6, no. 4, 2018.

H.L. Hao, D.R. Ni, H. Huang, D. Wang, B.L. Xiao, Z.R. Nie, Z.Y. Ma, “Effect of welding parameters on microstructure and mechanical properties of friction stir welded Al-Mg-Er alloy,” Material Science and Engineering, vol. 559, pp. 889-896, 2013. https://doi.org/10.1016/j.msea.2012.09.041

G. Elatharasan, V.S.S. Kumar, “Microstructural characterization and mechanical properties in friction stir welding of AA7075 aluminium alloy,” Advanced Materials Research, vol. 622-623, pp. 330-334, 2013. https://doi.org/ 10.4028/www.scientific.net/AMR.622-623.330

P.V. Kumar, G.M. Reddy, K.S. Rao, “Microstructure, mechanical and corrosion behaviour of AA7075 aluminium alloy friction stir welds,” Indian Welding Journal, vol. 51, no. 2, pp. 66-74. 2018. https://doi.org/10.22486/iwj.v51i2.170312

P. Sadeesh, M.V. Kannan, V. Rajkumar, P. Avinash, N. Arivazhagan, K.D. Ramkumar, S. Narayanan, “Studies on friction stir welding of AA2024 and AA6061 dissimilar metals,” Procedia Engineering, vol. 75, pp. 145-149, 2014. https://doi.org/10.1016/j.proeng.2013.11.031

J.S. Leon, V. Jayakumar, “Effect of tool shoulderpin cone angles in friction stir welding using non-circular tool pin,” Applied and Computational Mechanics, vol.6, no.3,pp 554-563, 2019. https://doi.org/10.22055/JACM.2019.29340.1585

R.S. Kumar, T. Rajaskaran, S.D. Singh, S. Kumar, P. Mishra, Priyanshushrivastav, S. Ravishankar, “Optimization of friction stir welding parameters to improve the mechanical and metallurgical properties of aluminium alloy AA5083 joints,” IOP Conference Series Materials Science and Engineering, vol. 912, no. 3, 2020, Article 032029. https://doi.org/10.1088/1757-899X/912/3/032029

C. Rathinasurigan, V.S.S. Kumar, “Optimization of submerged friction stir welding parameters of aluminium alloy using RSM and GRA,” Advances in Materials and Processing Technologies, vol. 7, no. 4, pp. 696-709, 2021. https://doi.org/10.1080/2374068X.2020.1793264

J.A. Ghani, H. Jamaluddin, M.N.A. Rahman and B.M.R. Deros, “Philosophy of taguchi approach and method in design of experiment,” Asian Journal of Scientific Research, no.6, pp. 27 – 37, 2013. https://doi.org/10.3923/ajsr.2013.27.37.

B.C. Oji, and S.A. Oke, “Optimization of bottling process using "hard" total quality management elements,” The TQM Journal, vol. 33, no. 2, pp. 473-502, 2020. https://doi.org/10.1108/TQM-03-2020-0057

Downloads

Published

How to Cite

Issue

Section

License

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.