Parametric Selection and Optimization for the Drilling Of AZ91 Magnesium Alloys Using the Taguchi Method Incorporating Direct and Aspect Parametric Ratios

doi: 10.14456/mijet.2023.4

Keywords:

Aspect ratios, drilling, magnesium AZ91 alloy, optimisation, response tableAbstract

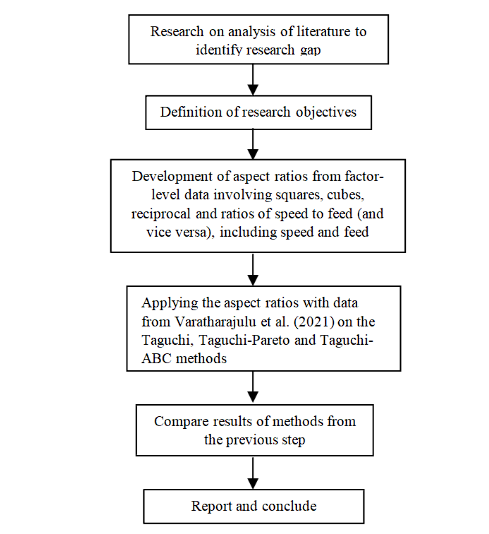

The central pursuit in drilling optimisation is to reduce, control and monitor the diverse process-oriented defects. However, in the drilling of AZ91 magnesium alloy, the optimisation approach adopted using the Taguchi technique still lacks complete capture of relevant data for the effective hole creation defect minimization. At present, the aspect ratios are completely ignored in the determination of optimal parametric settings using the factor-level response table evaluation route. This paper overcomes this shortcoming by introducing some aspect ratios into the computational framework of optimisation using the Taguchi method. Literature data regarding the drilling of AZ91 magnesium alloy was used to validate the proposed optimisation approach. The approach consists of defining the factor-level table to incorporate aspect ratio factors. Then, the orthogonal matrix, signal-to-noise ratios and the summarized signal-to-noise ratio (response) table are then declared. With the direct parameters of speed and feed considered in the literature sources for validating the method, aspect ratios were formulated to involve the ratios of speed to feed and vice-versa. Others are the square and reciprocals of speed and feed parameters. A total of eight alternatives were formulated and tested with each alternative consisting of the squares reciprocals or aspect ratios of the speed and feed parameters. Results showed that 41.67% of all the tested parameters significantly impact surface roughness during the drilling operation. These are the square and cube of feed rate, the reciprocals of the square and cube of speed and the ratio of the feed rate to speed. It is concluded that the study provides a useful route to analyzing the optimisation and performance potential of the drilling process for cost-effective drilling activities.

References

F. Miller, J. Blau and J. Shih, “Microstructural alterations associated with friction drilling of steel, aluminum, and titanium”, Journal of Materials Engineering and Performance, vol. 14, no. 5, pp 647-653, 2015. https://doi.org/10.1361/105994905X64558

K. Balamurugan, M. Uthayakumar, S.T. Kumaran, G.S. Samy, U.T.S. Pillai, “Drilling study on lightweight structural Mg/SiC composite for defence applications”, Defence Technology, vol. 15, no. 4, pp. 557-564, 2019. https://doi.org/10.1016/j.dt.2019.01.002

A. Beranoagirre, G. Urbikain, R. Marticorena, A. Bustillo & L. López de Lacalle, “Sensitivity analysis of tool wear in drilling of titanium aluminides”, Metals, vol. 9, no. 3, Article 297, 2019. https://doi.org/10.3390/met9030297

S. Kannan, S. Pervaiz, M.P. Jahan and D. Venkatraghaven, “Cryogenic drilling of AZ31 magnesium syntactic foams”, Materials, vol. 13, no. 18, Article 4094, 2020. https://doi.org/10.3390/ma13184094

S. Bhowmick, M.J. Lukitsch, A.T. Alpas, “Dry and minimum quantity lubrication drilling of cast magnesium alloy (AM60)”, International Journal of Machine Tools and Manufacture, vol. 50, no. 5, pp. 444-457, 2010. https://doi.org/10.1016/j.ijmachtools.2010.02.001

E. Kilickap & M. Huseyinoglu, “Selection of optimum drilling parameters on burr height using response surface methodology and genetic algorithm in drilling of AISI 304 stainless steel”, Materials and Manufacturing Processes, vol. 25, no. 10, pp. 1068-1076, 2010. https://doi.org/10.1080/10426911003720854

E. Kilickap, M. Huseyinoglu, & A. Yardimeden, “Optimization of drilling parameters on surface roughness in drilling of AISI 1045 using response surface methodology and genetic algorithm”, The International Journal of Advanced Manufacturing Technology, vol. 52, no. 1-4, pp. 79-88, 2010. https://doi.org/10.1007/s00170-010-2710-7

A. Mishra and A. Gangele, 2012, Application of Taguchi method in optimization of tool flank wear width in turning operation of AISI 1045 steel, Industrial Engineering Letters, vol. 2, no.8, pp 1-8, 2012.

Ş. Yazman, U. Köklü, L. Urtekin, S. Morkavuk, L. Gemid, “Experimental study on the effects of cold chamber die casting parameters on high-speed drilling machinability of casted AZ91 alloy”, Journal of Manufacturing Processes, vol. 57, pp. 136-152, 2020. https://doi.org/10.1016/j.jmapro.2020.05.05

P. Umamaheswarrao, B.R. Sankar, M. Pardhasaradhi, K. Rajasekharababu, “Experimental study on drilling force during drilling of AZ91D magnesium alloy”, Materials Today: Proceedings, vol. 44, no. 1, pp. 305-308, 2021. https://doi.org/10.1016/j.matpr.2020.09.471

R.S. Buradagunta, K.V. Ganesh, P. Pavan, G. Vadapalli, C. Swarnalatha, P. Swapna, P. Bindukumar, G.P.K. Reddy, “Effect of aluminium content on machining characteristics of AZ31 and AZ91 magnesium alloys during drilling”, Journal of Magnesium and Alloys, vol. 4, no. 1, pp. 15-21, 2016. DOI: 10.1016/j.jma.2015.10.003

U. Köklü, H. Coban, “Effect of dipped cryogenic approach on thrust force, temperature, tool wear and chip formation in drilling of AZ31 magnesium alloy”, Journal of Materials Research and Technology, vol. 9, no. 3, May–June 2020, pp. 2870-2880. https://doi.org/10.1016/j.jmrt.2020.01.038

N. Sivashankar, R. Viswanathan, K. Periasamy, R. Venkatesh, S. Chandrakumar, “Multi-objective optimization of performance characteristics in drilling of Mg AZ61 using twist end mill drill tool”, Materials Today: Proceedings, vol. 37, no. 2, pp. 214-219, 2021. https://doi.org/10.1016/j.matpr.2020.05.033

L. Li & N. D. Nam, “Effect of yttrium on corrosion behavior of extruded AZ61 mg alloy”, Journal of Magnesium and Alloys, vol. 4, no. 1, pp. 44-51, 2016. https://doi.org/10.1016/j.jma.2015.11.008

C. Liang, C. Li, X.X. Lv, J. An, “Correlation between friction-induced microstructural evolution, strain hardening in subsurface and tribological properties of AZ31 magnesium alloy”, Wear, vol. 312, no. 1–2, pp. 29-39, 2014. https://doi.org/10.1016/j.wear.2014.02.001

S.Y. Liang, A. Shih, “Multiple point cutting processes, in Analysis of Machining and Machine Tools”, 2016, Springer New York, NY, XIV, 230p https://doi.org/10.1007/978-1-4899-7645-1_3

P. Adwait, N. Kamble, and Y. Kamble, “A review paper on friction drilling process on various materials”, IOSR Journal of Mechanical and Civil Engineering, vol. 16, no 6, pp. 1, 2019

F. Berzosa, B. De Agustina, , & E. Rubio, “Tool selection in drilling of magnesium UNSM11917 pieces under dry and MQL conditions based on surface roughness”, Procedia Engineering, vol. 184, 117-127, 2017. https://doi.org/10.1016/j.proeng.2017.04.076

S. Bhowmick, A.T. Alpas, “The role of diamond-like carbon coated drills on minimum quantity lubrication drilling of magnesium alloys”, Surface and Coatings Technology, vol. 205, no. 23–24, pp. 5302-5311. 2011. https://doi.org/10.1016/j.surfcoat.2011.05.037

B. De Agustina, F. Berzosa, E.M. Rubio, M.M. Marín, “Experimental study of magnesium drilling based on the surface quality”, Procedia CIRP, vol. 79, pp. 74-78, 2019. https://doi.org/10.1016/j.procir.2019.02.014

R. Kumar , D.R. Prajapati & S. Singh, “Implementation of Taguchi methodology for defect reduction in manufacturing industry: A case study”, International Journal of Industrial Engineering Research and Development, vol. 2, no. 1, https://doi.org/10.34218/ijierd.2.1.2011.001

R. Manohara, A. Harinath, Application of taguchi method for optimization of process parameters in drilling operation, International Journal of Trend in Scientific Research and Development, vol. 3, no. 4, pp. 1052-1057, 2009.

S.A. Oke, A.A. Adekoya, “Aspect ratio consideration in the optimisation of maintenance downtime for handling equipment in a container terminal, Engineering Access, vol. 8, no. 1, pp. 129-141, 2022. https://doi.org/10.14456/mijet.2022.18

R.M. Adegoke and S.A. Oke, “Optimising turning parameters for the turning operations of Inconel X750 alloy with nanofluids using direct and aspect ratio-based Taguchi methods”, International Journal of Industrial Engineering and Engineering Management, Vol. 3, No. 2, pp. 59-76, 2021. https://doi.org/10.24002/ijieem.v3i2.5457

N. Wojtowicz, I. Danis, F. Monies, P. Lamesle, R. Chieragati, “The influence of cutting conditions on surface integrity of a wrought magnesium alloy”, Procedia Engineering, vol. 63, pp. 20-28, 2013. https://doi.org/10.1016/j.proeng.2013.08.212

M. Varatharajulu, M. Duraiselvam, M.B. Kumar, G. Jayaprakash, N. Baskar, “Multicriteria decision making through TOPSIS and COPRAS on drilling parameters of magnesium AZ91”, Journal of Magnesium and Alloys, In Press, 2021. https://doi.org/10.1016/j.jma.2021.05.006

B. Akyȕz, “A study on wear and machinability of AZ series (AZ01-AZ91) cast magnesium alloys”, Kovove Materialy, vol. 52, no. 5, pp. 255-262, 2014. https://doi.org/10.4149/km_2014_5_255

E. Rubio, M. Villeta, J. Valencia, & J. Sáenz de Pipaón, “Cutting parameter selection for efficient and sustainable repair of holes made in hybrid Mg–Ti–Mg component stacks by dry drilling operations”, Materials, vol. 11, no. 8, Article 1369, 2018. https://doi.org/10.3390/ma11081369

P.S. Roodposhti, A. Sarkar, K.L. Murty & R.O. Scattergood, “Effects of microstructure and processing methods on creep behavior of AZ91 magnesium alloy”, Journal of Materials Engineering and Performance, vol. 25, no. 9, pp. 3697-3709, 2016. https://doi.org/10.1007/s11665-016-2222-1

K. Gunasekaran, K.G. Pradeep, R. Thanigaivelan, R. Arunachalam, V. Shanmugam, “Optimization of turning parameters of cryogenic soaked AZ91 magnesium alloy using TOPSIS coupled taguchi technique”, Journal of New Materials for Electrochemical Systems, vol. 24, no. 1, pp. 49-54, 2021. https://doi.org/10.14447/jnmes.v24i1.a09

L. Yang, Q. Jiang, M. Zheng, B. Hou & Y. Li, “Corrosion behavior of mg–8li–3Zn–Al alloy in neutral 3.5% NaCl solution”, Journal of Magnesium and Alloys, vol. 4, no. 1, pp. 22-26, 2016. https://doi.org/10.1016/j.jma.2015.12.002

O. Asal, “Optimization of surface roughness in turning of AZ31 magnesium alloys with Taguchi method”, Gazi University Journal of Science, Part A: Engineering and Innovation, vol. 6, no. 1, pp. 25-32, 2019. http://dergipark.gov.tr/gujsa

X. Yue, K. Kitazono, X. Yue & B. Hur “Effect of fluidity on the manufacturing of open cell magnesium alloy foams”, Journal of Magnesium and Alloys, vol. 4, no. 1, pp. 1-7, 2016. https://doi.org/10.1016/j.jma.2015.11.007

H. Ren, W. Hu, D. Li, X. Zeng, X. Yang, X. Zeng, X. Yang, B. Huang & Y. Liu, “Atomic relaxation, stability and electronic properties of Mg2Sn (100) surfaces from AB-initio calculations”, Journal of Magnesium and Alloys, vol. 4, no. 1, pp. 62-67, 2016. https://doi.org/10.1016/j.jma.2016.02.002

A. Mahata & K. Sikdar, “Molecular dynamics simulation of nanometer scale mechanical properties of hexagonal Mg Li alloy” Journal of Magnesium and Alloys, vol. 4, no. 1, pp. 36 43, 2016. https://doi.org/10.1016/j.jma.2015.12.001

F. Pan , X. Chen, T. Yan, T. Liu , J. Mao, W. Luo, Q. Wang, J. Peng, A. Tang & B. Jiang, “A novel approach to melt purification of magnesium alloys”, Journal of Magnesium and Alloys, vol. 4, no. 1, pp. 8-14, 2016. https://doi.org/10.1016/j.jma.2016.02.003

E. Morin, J. Masounave & E. Laufer, “Effect of drill wear on cutting forces in the drilling of metal-matrix composites”, Wear, vol. 184, no. 1, pp. 11-16, 1995. https://doi.org/10.1016/0043-1648(94)06541-1

S. Sun, Y. Qin, H. Zhou, Y. Du & C. He, “Experimental investigation of the isothermal section at 400 °C of the MgCeSr ternary system”, Journal of Magnesium and Alloys, vol. 4, no. 1, pp. 30-35, 2016. https://doi.org/10.1016/j.jma.2015.11.009

L. Ruan, S.Ezaki, F. Masahiro, S. Shen & Y. Kawamura, “Forming of magnesium alloy by underwater shock wave”, Journal of Magnesium and Alloys, vol. 4, no. 1, pp. 27-29, 2016. https://doi.org/10.1016/j.jma.2015.12.003

Y. Kayir,“Optimization of the cutting parameters for drilling magnesium alloy AZ91”, Materials Testing, vol. 56, no. 1, pp. 47-53, 2014. https://doi.org/10.3139/120.110523

U. Köklü, O. Koçar, and S. Morkavuk, K. Giasin, Ö. Ayer, “Influence of extrusion parameters on drilling machinability of AZ31 magnesium alloy”, Proceedings of the Institution of Mechanical Engineers, Part E: Journal of Process Mechanical Engineering, 2022. https://doi.org/10.1177/09544089221080820

A. Mohd, S. Siti, S. Mohd, Y. Mohd, M. Noraiham, A. Mohd, A. Zulkeflee, M. Effendi, “Surface roughness optimization in drilling process using response surface method (RSM)”, Jurnal Teknologi (Sciences & Engineering), vol. 66, no. 3, pp. 29–35, 2014.

E. Gariboldi, “Drilling a magnesium alloy using PVD coated twist drills”, Journal of Materials Processing Technology, vol. 134, no. 2, pp. 287-295, 2003.

K. Shi, D. Zhang, J. Ren, C. Yao, & X. Huang, “Effect of cutting parameters on machinability characteristics in Milling of magnesium alloy with carbide tool”, Advances in Mechanical Engineering, vol. 8, no. 1, 2016. https://doi.org/10.1177/1687814016628392

S. Devadharshini, B. Rajeswari, R. Surendran, “Machining characteristics of Al5052 hybrid composites fabricated by stir casting process”, International Advanced Research Journal in Science, Engineering and Technology, vol. 8, no. 5, pp. 681-687, 2021.

J. Wang, Y.B. Liu, J. An, L.M. Wang, “Wear mechanism map of uncoated HSS tools during drilling die-cast magnesium alloy”, Wear, vol. 265, no. 5–6, pp. 685-691, 2008. https://doi.org/10.1016/j.wear.2007.12.009

Downloads

Published

How to Cite

Issue

Section

License

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.