Enhancement of Brake Pads Production Planning with Time Management and Process Condition Using VBA on Microsoft Excel

doi: 10.14456/mijet.2023.7

Keywords:

Production improvement, Production management, Production planning, VBA, Brake pads production planningAbstract

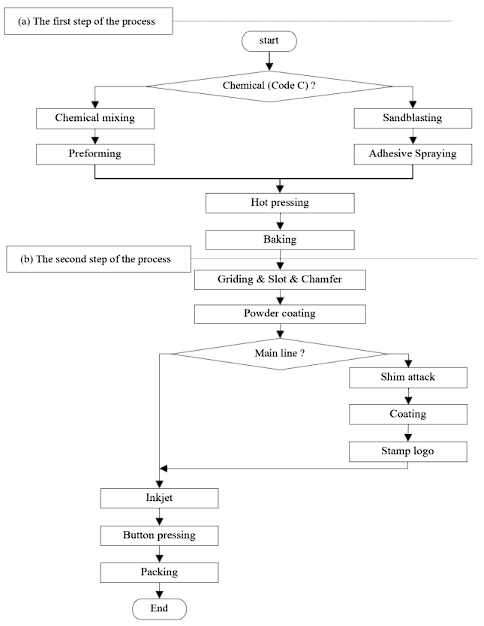

This research aims to increase the efficiency of work management in the production planning process. This research uses an industrial engineering method based on a time and motion study to record operational data and create a standard planning process in the production process. It also uses the VBA on Microsoft Excel to analyze data and facilitate the work of the operators. The results of time data recording can be used to calculate the standard time as part of setting work sequence standards. The trials for two sessions (session 1 is a daytime production and session 2 is a nighttime production) with different production process results showed that the program could be used to plan the two sessions’ production with no difference. The usability test revealed that programmed planning results were greater in percentage mean accuracy compared to actual production than existing planning. There was a 72.17% increase in efficiency in session 1 and a 73.48% increase in efficiency in session 2. This was a statistically significant increase in efficiency. Therefore, it can be concluded that using the above principles and methods can improve the production planning process to be able to plan production more accurately.

References

A. K. a. R. Binder, John Bell. (2020, 11 February ). automotive industry.Available:https://www.britannica.com/technology/automotive-industry

I. Bhiradi and B. Singh, "Work measurement approach for productivity improvement in a heavy machine shop," in 5th International & 26th All India Manufacturing Technology, Design and Research Conference (AIMTDR 2014), 2014.

S. R. Kumar, V. N. Nathan, S. M. Ashique, V. Rajkumar, and P. A. J. M. T. P. Karthick, "Productivity enhancement and cycle time reduction in toyota production system through jishuken activity–Case study," vol. 37, pp. 964-966, 2021.

C. Duran, A. Cetindere, and Y. E. Aksu, "Productivity improvement by work and time study technique for earth energy-glass manufacturing company," vol. 26, pp. 109-113, 2015.

P. H. A. Cury, J. J. G. Saraiva, and Produção, "Time and motion study applied to a production line of organic lenses in Manaus Industrial Hub," vol. 25, pp. 901-915, 2018.

S. Gnanavel, V. Balasubramanian, and T. J. P. M. Narendran, "Suzhal–An alternative layout to improve productivity and worker well-being in labor demanded lean environment," vol. 3, pp. 574-580, 2015.

M. A. Ballermann, N. T. Shaw, D. C. Mayes, R. T. Gibney, and J. I. Westbrook, "Validation of the Work Observation Method By Activity Timing (WOMBAT) method of conducting time-motion observations in critical care settings: an observational study," BMC Med Inform Decis Mak, vol. 11, no. 1, p. 32, May 17, 2011.

K. S. Al-Saleh, "Productivity improvement of a motor vehicle inspection station using motion and time study techniques," Journal of King Saud University-Engineering Sciences, vol. 23, no. 1, pp. 33-41, 2011.

N. A. Dudley, "Work-Time Distributions and Motion-Time Patterns," in Work Measurement: Some Research Studies, N. A. Dudley, Ed. London: Macmillan Education UK, 1968, pp. 37-47.

W. Cheewaworanontree, P. Rontlaong, and N. J. T. J. o. I. T. S. S. R. U. Boonrak, "Motion and time study: a case study on a short-time hydrostatic failure pressure testing process of rigid PVC plain-end pipes," vol. 6, no. 1, pp. 26-38, 2018.

K. S. J. J. o. K. S. U.-E. S. Al-Saleh, "Productivity improvement of a motor vehicle inspection station using motion and time study techniques," vol. 23, no. 1, pp. 33-41, 2011.

T. Melton, "The benefits of lean manufacturing: what lean thinking has to offer the process industries," Chemical engineering research design, vol. 83, no. 6, pp. 662-673, 2005.

M. F. A. Ana Pereira, David Silva, Anabela C. Alves, José A.Oliveira, Isabel Lopes, Manuel C.Figueiredo, "Reconfigurable standardized work in a lean company–a case study," vol. 52, pp. 239-244, 2016.

M. S. Seppanen, "Developing industrial strength simulation models using visual basic for applications (VBA)," in 2000 Winter Simulation Conference Proceedings (Cat. No. 00CH37165), 2000, vol. 1, pp. 77-82: IEEE.

C. T. Maravelias and C. Sung, "Integration of production planning and scheduling: Overview, challenges and opportunities," vol. 33, no. 12, pp. 1919-1930, 2009.

Downloads

Published

How to Cite

Issue

Section

License

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.