Preliminary Experimental of Biomass Gasification Process with Open Core Throat Less Downdraft Gasifier

Main Article Content

Abstract

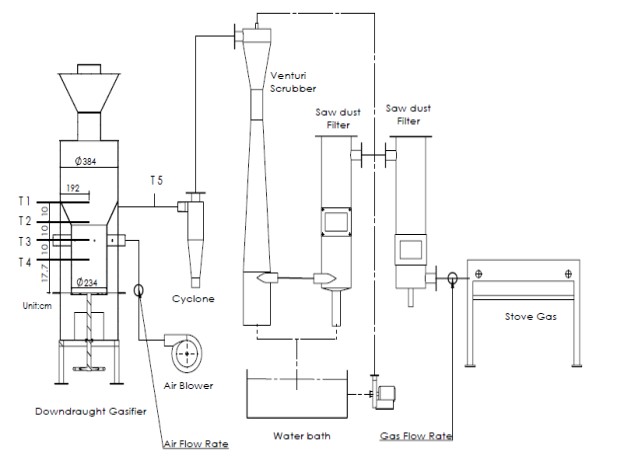

Gasification has been considered a promising approach to converting biomass into useful gaseous products. Downdraft gasifiers are famous for engine applications and used for thermal applications. The product gas has to meet the individual requirements of different end users or applications. The downdraft gasifier based on open core throat less design has been developed according to its suitability for small-sized biomass. The preliminary experiment investigated gasifying characteristics by studying the temperature distribution within the gasifier. This study used three kinds of biomass: Eucalyptus wood chip, Mimosa wood twig, and wood pellet. The results showed that the temperature distribution within the gasifier for each zone corresponds with the character of the gasifying process within the downdraft gasifier. Moreover, the temperature profiles for a gasifying process for all three biomass tests were in the same pattern. The maximum temperature was in the combustion zone (T3). The maximum temperature at the combustion zone for the Eucalyptus wood chip is the highest compared with the maximum temperature at the combustion zone of the Mimosa wood twig and wood pellet. The temperature at the combustion zone (T3) of the Eucalyptus wood chip, Mimosa wood twig, and the wood pellet were 838, 783, and 620 °C, respectively. The temperature at the combustion zone results in the temperature at the reduction zone. The average temperature at the reduction zone for gasifying all three biomass feeds ranges from 470-514 °C. While the temperature at the pyrolysis zone and the gas exit are not significantly different for all three biomass feeds. These results showed that the reaction within the gasifier could carry out continuously with a suitable temperature in each zone as per the design.

Article Details

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

References

Govindjee, WJ.; The photosynthetic process. In Concepts in photobiology:photosynthesis and photomorphogenesis, Singhai, G.S.; Renger, G., Sopory, SK, Irrgang, K.D., Govindjee., editors. Boston: Kluwer Academic Publishers; 1999, 11-51.

Piriou, B.; Vaitilingom, G.; Veyssiere, B.; Cuq, B.; Rouau, X.; Potential direct use of solid biomass in internal combustion engines. Progr Energy Combust Sci 2013, 39, 169-188.

Wenbin, Zhang.; Hao, L,; Irfan, U.H.; York, N.; Philipp, S.; Holger, O.; Alexander, S.; and Axel, K.; Gas cleaning strategies for biomass gasification product gas. International Journal of Low Carbon Technologies 2012, 7, 69-74.

Baldwin, R.M.; Magrini, K.A.; Nimlos, M.R.; Pepiot, P.; Donohoe, B.S.; Hensley, J.E.; Current reseach on thermochemical conversion of biomass at the National Renewable Energy Laboratory. Appl Catal B: Environ 2012, 115-116.

Deshmukh, R.; Jacobson, A.; Chamberlin, C.; Kammen, D.; Thermal gasification or drect combustion. comparison of advanve cogeneration systems in the sugarcane industry. Biomass Bioenergy 2013, 55, 163-174.

Mohammad, A.; Biomass gasification gas cleaning for downstream applications:A comparative critical Review. Renewable and Sustainable Energy Reviews 40 , 2014, 118-132.

Mekendy, P.; Energy production from biomass (part 1) : oveview of biomass. Bioresource Technology 2002, 83, 37-46.

Basu, P.; Biomass gasification, Pyrolysis, and Torrefaction: Practical Design and Theory.Secon edition, 2013, Academic Press is an imprint of Elsevier, London, UK.

Mekendy, P.; Energy production from biomass (part 3) : oveview of biomass. Bioresource Technology 2002, 83, 55-63.

Reed, T.B.; Das, A.; Handbook of biomass downdraft gasifier engine system.The Biomass Foundation Press, 1984, Colorado, USA.

Groveneveld, M.J.; Japp, J.H.; Gasification of various eastes annular co current moving bed gasifier, Proceeding of 2 nd EL conference on energy from biomass. Applied Science Publisher, 1983, 406-407.

Kaupp, A.; Gasification of rice husk:Theory and Praxis. Publication of Dt. Zentrum fur Entwickhings technologies; Wiesbaden; Vieweg, 1984.

Kaupp, A.; Goss, J.R.; Small scale gas producer engine system. Published by GATE/GTZ. Germany, 1984. Brigwater, A,V.; Thermochemical processing of biomass. Butterworth, UK, 1984.

Devi, L.; Ptasinski, K.J.; Janssen F.; A review of the primary measures for tar elimination in biomass gasification process. Biomass Bioenergy 2003, 24, 125-140.

Corella, J.; Toledo, J.M.; Molina, G.; Calculation of the conditions to get less than 2 g tar /Nm3 in a fluidized bed biomass gasifier. Fuel Process Technol 2006, 87, 841-846.

Jain, A.K.; Goss, J.R.; Determination of reactor sealing factors for throatless rice husk gasifier. Biomass and Bioenergy 2000,18, 249-256.

Tiwari, G.; Sarkar, B.; Ghosh, L.; Design Parameters for a Rice husk throatless Gasifier reactor. Agricultural Engineering International: the CIGR Journal of Scientific Research and Development 2006, 8.

Sims, R., Climate change solutions from biomass, bioenergy and biomaterials. Agricultural Engineering International: the CiCR Journal of Scientific Research and Development. 2003, 5.