Pyrolysis of Latex Sediment from Concentrated Latex Industry and Properties of Pyrolytic Products

Main Article Content

Abstract

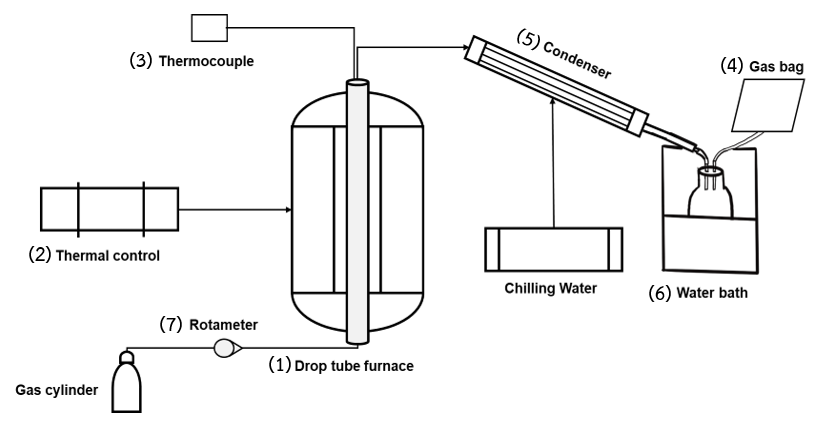

Concentrated latex is an intermediate rubber product in Thailand. It is an important industry that generates income for the country and Its southern region. The main products of the latex factory were concentrated latex and skim blocks. The industrial waste from the concentrated latex factory is called latex sediment. It appears to be a white mixed light-yellow sludge or a dark brown color, contains magnesium compounds, and phosphorus is an important element. Therefore, finding appropriate measures for rubber production and environmentally friendly industrial waste management is important. Therefore, this study investigates the pyrolysis of latex sediment as an alternative to industrial waste management. Pyrolysis of 100 g of latex sediment was performed at 300 °C, 500 °C, and 700 °C. From the experiment, it was found that the properties of the liquid product from the pyrolysis process at 500 °C were alkaline, with a pH of 9.45. However, acetic acid was the highest amount of organic substance in the liquid product. Substances in the amine and amide groups were also observed, a base result for the liquid product exhibiting an alkaline value. The pH is an important factor in the decomposition of organic substances under anaerobic conditions. Therefore, a 1 wt% liquid product was used in a volume of 13.5 mL, which is the most appropriate amount because it uses the least amount of liquid product to adjust the alkalinity of the skim latex serum before entering the anaerobic fermentation system. Pyrolysis is an environmentally friendly option for managing factory latex sediments for sustainable production and creating a good image for the organization.

Article Details

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

References

Wichakit, S. Thai rubber industry Growth trends in 2022. https://www.v-servelogistics.com/media/vserve2017/file_pdf/22020160904_NA-JAN2022-Siwakorn.pdf.2022.

Jawjit, W.; Pavasant, P.; Kroeze, C. Evaluating environmental performance of concentrated latex production in Thailand. Journal of Cleaner Production, 2015; 98, 84-91. (Jawjit, 2015). https://doi.org/10.1016/j.jclepro.2013.11.016

Chinnawong, P.; Dhanaraks, K.; Siriratpiriya, O. Effect of rubber latex sludge used as magnesium source for growth of oil palm in main nursery stage. The 15th Graduate Research Conferences. 776-782. Khon Kaen University. (Phiromkhwan, 2014). 2014.

Korwutthikulrangsri, S.; Chaisuksan, Y.; Niyomdecha, S.; Saengkhao, P. Autho Modification of concentrated latex sludge using effective microorganisms. Rubber Industry Development Project Set, TRF. Project code RDG5050102. 2009.

Saeseng, L. Efficient biogas production from organic wastes in concentrated latex factory by integrated pyrolysis and anaerobic digestion [Master’s thesis]. Prince of Songkhla University. 2018.

Asadullah, M.; Rahman, M.A.; Ali, M.M.; Rahman, M.S.; Motin, M.A.; Sultan, M.B.; Alam, M.R. Production of bio-oil from fixed bed pyrolysis of bagasse. Fuel. 2007; 86, 2514-2520. https://doi.org/10.1016/j.fuel.2007.02.007

Benmad, A. Production and characterization of bio-fuel from sugarcane bagasse by using pyrolysis and pelletization [Master’s thesis]. Prince of Songkhla University. 2018.

Sohgratok, N. Biogas production from decanter cake of plam oil mill withwastewater from frozen seafood industry [Master’s thesis]. Prince of Songkhla University. 2012.