Evaluation and Reduction of the Carbon Footprints Associated with Steviol Glycoside Production

Main Article Content

Abstract

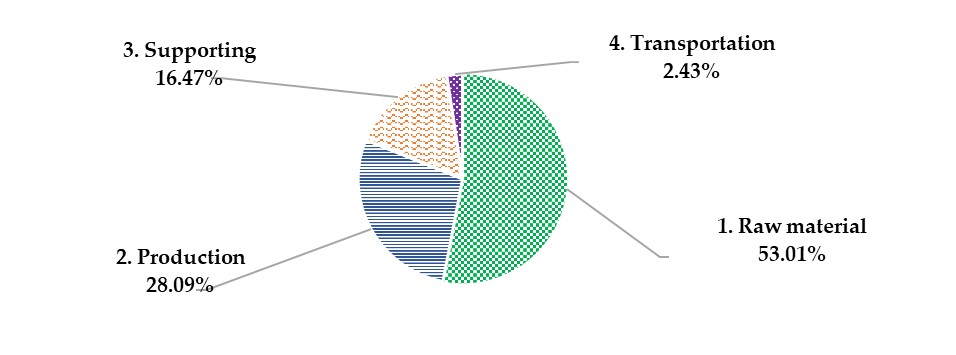

This study aims to evaluate the carbon footprint generated in each step of stevia sweetener (steviol glycosides) production and to find out how to reduce the impact of the sweetener's greenhouse gas (GHG) emissions. In addition, a comparison of the carbon footprints of the sweetener and sucrose is included. A cradle-to-gate LCA was conducted on steviol glycosides (purified rebaudioside A, RA95) production in Thailand. The carbon footprint assessment method is based on the guidelines of the Food Institute, Ministry of Industry in Thailand, corresponding to ISO 14067 and PAS 2050. The study evaluates the carbon footprint by employing two sources of emission factors from the Thailand Greenhouse Gas Management Organisation database for carbon footprint and OpenLCA Version 1.10.3 with eco-invent database Version 2.2 for comparing the carbon footprint and finding out other impacts. The result from OpenLCA reveals the impact on marine aquatic ecotoxicity, followed by the Depletion of abiotic resources and human toxicity. The results showed that a kilogram of the RA95 releases 32.07 kilograms of carbon dioxide equivalent. The highest GHG emissions came from the raw material procurement process, with 53.01%, followed by production, support system, and material transportation, with 28.09%, 16.47%, and 2.43%, respectively. The three production steps with the highest GHG emissions were the second crystallization, the first crystallization, and the drying process, respectively. The RA95 release a carbon footprint 3.55 times lower than sucrose for the same level of sweetness. The recommendations to reduce the carbon footprint in production are to reduce natural gas usage by improving boiler efficiency and reduce electricity usage by installing an automatic shutdown system for cooling machines (chiller), depending on the production volume. The findings revealed a lower carbon footprint of 0.33 kgCO2eq per kilogram of product after improvement.

Article Details

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

References

World Health Organization. (2016, April 21). Global report on diabetes. Technical document. https://www.who.int/publications/i/item/9789241565257

World Health Organization. (2023, December 23). Malnutrition. Fact sheet. https://www.who.int/news-room/fact-sheets/detail/malnutrition

Ministerial regulations: determine the excise tax tariff. (2020, September 16). Royal Gazette, 134(95A), 111 (in Thai).

Ministry of Finance. (2021). Ministerial regulations: determine the excise tax tariff (No. 16) (in Thai).

Warshaw, H.; Edelman, S.V. Practical Strategies to Help Reduce Added Sugars Consumption to Support Glycemic and Weight Management Goals. Clinical Diabetes. 2021, 39(1), 45-56.

International Sweeteners Association. (n.d.) Safety®ulation. https://www.sweeteners.org/safety-regulation.

Khilar, S.; Singh, A.P.; Biagi, M.; Sharma, A. An Insight into attributes of Stevia rebaudiana Bertoni: Recent advanced in extraction techniques, phytochemistry, food applications and headlth benefits. Journal of Agriculture and Food Research. 2022, (10).

FAO and WHO. Compendium of Food Additive Specifications. Joint FAO/WHO Expert Committee on Food Additives (JECFA), 91st Meeting – Virtual meeting, 1–12 February 2021. FAO JECFA Monographs No. 26. Rome. https://doi.org/10.4060/cb4737en

CBI Ministry of Foreign Affiars. Entering the European market for stevia. Market information. 2022. https://www.cbi.eu/market-information/natural-food-additives/stevia/market-potential

PureCircle. PureCircle White Paper Series Carbon and Water: Understanding and Reducing Impacts. 2015. https://purecircle.com/app/uploads/purecircle-carbon-and-water-footprint1.pdf

Suckling, J.; Morse, S.; Murphy, R.; Astley, S.; Halford, J.C.G.; Harrold, J.A.; Le-Bail, A.; Koukouna, E.; Musinovic, H.; Perret, J.; Raben, A.; Roe, M.; Scholten, J.; Scott, C.; Stamatis, C.; Westbroek, C. (2023). Environmental life cycle assessment of production of the high intensity sweetener steviol glycosides from Stevia rebaudiana leaf grown in Europe: The SWEET project. The International Journal of Life Cycle Assessment. 2023, 28, 221-233.

Rodolfo, S.; Leonor, G. Life Cycle Assessment comparing Sugar Cane vs. Stevia Rebaudiana Sweetener, for Mexico City Market. Instituto Tecnológico de Estudios Superiores de Monterrey-CEM; and 2 Instituto de Ingeniería, UNAM, Mexio. 2011.

Ministry of Natural Resources and Environment. Thailand’s long-term low greenhouse gas emission development strategy (revised version). 2022. https://unfccc.int/sites/default/files/resource/Thailand%20LT-LEDS%20%28Revised%20Version%29_08Nov2022.pdf

Food Institute. Guideline for evaluating carbon footprint on product for food industry. Ministry of Industry, Bangkok. 2013. (in Thai).

Prakash, I.; DuBois, G.E.; King, G.A.; Upreti, M. Rebaudioside A composition and method for purifying rebaudioside A. United States Patent Application Publication, US2007/0292582 A1, December 20. 2007.