Film Development of Chitosan from Mussel Shells and Pacific White Shrimp Shells

Main Article Content

Abstract

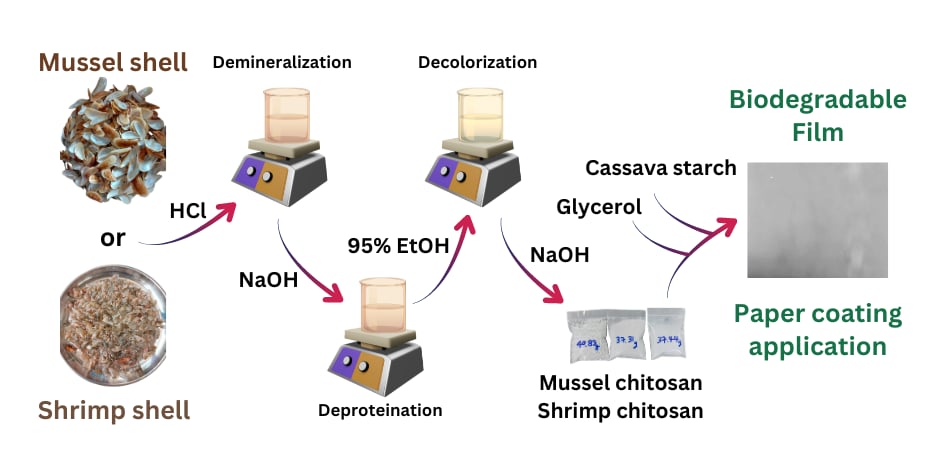

The rapid expansion of Thailand's aquatic food processing industry has generated significant waste, prompting environmental concerns. This research aims to repurpose waste, specifically mussel and shrimp shells, to extract chitosan, a natural alternative to harmful chemicals. The primary goal is to create compostable packaging materials and preservation techniques while adding value to industry waste. The study investigated the properties of the extracted chitosan, optimized the chitosan films, and explored their use as paper coatings. The study thoroughly investigates mussel and shrimp shell-derived chitosan properties, including color value, pH, moisture, ash, and nitrogen content. Chitosan yield is 35% for mussel shells and 13.3% for shrimp shells, with a bright color and pH values of 7.32 and 7.26, respectively. Mussel shells have lower moisture (0.38%) and higher ash content (96.50%) compared to shrimp shells (4.07% moisture, 10.67% ash). Nitrogen content is 6.40% for mussel shells and 7.99% for shrimp shells. Regarding chitosan films, Method 4, a mixture of cassava starch and chitosan at a 1:0.6 ratio with 40% glycerol by weight, is identified as the optimal production method. The resulting chitosan-coated paper exhibits similar properties, making it suitable for sustainable packaging. Therefore, this research emphasizes repurposing waste from the aquatic food processing industry to promote sustainability and create livelihoods for farmers while addressing environmental challenges. Mussel shells are recommended as the primary raw material due to their larger volume and lower cost than shrimp shells. This research highlights chitosan's potential to address environmental issues and foster sustainable practices in the food processing industry.

Article Details

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

References

Avérous, L.; Fringant, C.; Moro, L. Plasticized starch-cellulose interactions in polysaccharides composites. Polymer 2001, 42, 6565-6572. https://doi.org/10.1016/S0032-3861(01)00125-2

Arancibia, M.Y.; Aleman, A.; Calvo, M.M.; Lopez-Caballero, M.E.; Montero, P.; Gomez-Guillen, M.C. Antimicrobial and antioxidant chitosan solutions enriched with active shrimp (Litopenaeus vannamei) waste materials. Food Hydrocoll. 2014, 35, 710-717. https://doi.org/10.1016/j.foodhyd.2013.08.026

Je, J.Y.; Kim, S.K. Antimicrobial action of novel chitin derivative. Biochimica et Biophysica Acta 2006, 1760, 104-109. https://doi.org/10.1016/j.bbagen.2005.09.012

Costa, E.M.; Silva, S.; Pina, C.; Tavaria, F.K.; Pintado, M.M. Evaluation and insights into chitosan anti-microbial activity against anaerobic oral pathogens. Anaerobe 2012, 18, 305-309. https://doi.org/10.1016/j.anaerobe.2012.04.009

Begin, A.; Calsteren, M.R.V. Antimicrobial films produced from chitosan. Int. J. Biol. Macromol. 1999, 26, 63-67. https://doi.org/10.1016/S0141-8130(99)00064-1

Ngo, D.-N.; Kim, M.-M.; Kim, S.-K. Chitin oligosaccharides inhibit oxidative stress in live cells. Carbohydr. Polym. 2008, 74, 228−234. https://doi.org/10.1016/j.carbpol.2008.02.005

Rinaudo, M. Chitin and chitosan: Properties and applications. Prog. Polym. Sci. 2006, 31, 603−632. https://doi.org/10.1016/j.progpolymsci.2006.06.001

Arvanitoyannis, I.S.; Nakayama, A.; Aiba, S.-I. Chitosan and gelatin based edible films: State diagrams, mechanical and permeation properties. Carbohydr. Polym. 1998, 37, 371−382. https://doi.org/10.1016/S0144-8617(98)00083-6

Elassal, M.; El-Manofy, N.Chitosan nanoparticles as drug delivery system for cephalexin and its antimicrobial activity against multiidrug resistent bacteria. Int. J. Pharm. Sci. 2019, 11, 14−27. https://doi.org/10.22159/ijpps.2019v11i7.33375

Haque, T.; Chen, H.; Ouyang, W.; Martoni, C.; Lawuyi, B.; Urbanska, A. M.; Prakash, S. Superior cell delivery features of polyethylene glycol incorporated alginate, chitosan, and poly-L-lysine microcapsules. Mol. Pharmaceutics 2005, 2, 29−36. https://doi.org/10.1021/mp049901v

Kim, H.-J.; Chen, F.; Wang, X.; Rajapakse, N.C. Effect of chitosan on the biological properties of sweet basil (Ocimum basilicum L.). J. Agric. Food Chem. 2005, 53, 3696−3701. https://doi.org/10.1021/jf0480804

Verbeeck, R.M.H.; Haiben, M.; Thin, H.P.; Verbeek, F. Solubility and solution behaviour of strontium hydroxyapatite. Zeitschrift für Physikalische Chemie 1977, 108, 203−215. https://doi.org/10.1524/zpch.1977.108.2.203

Yamada, K.; Akiba, Y.; Shibuya, T.; Kashiwada, A.; Matsuda, K.; Hirata, M. Removal of phenol compounds by the combined use of tyrosinase and chitosan. Abstr. Pap. Am. Chem. Soc. 2005, 230, U4039.

Yen, M.-T.; Yang, J.-H.; Mau, J.-L. Physicochemical characterization of chitin and chitosan from crab shells. Carbohydr. Polym. 2009, 75, 15−21. https://doi.org/10.1016/j.carbpol.2008.06.006

Mollah, M.Z.I.; Akter, N.; Quader, F.B.; Sultana, S.; Khan, R.A. Biodegradable Colour Polymeric Film (Starch-Chitosan) Development: Characterization for Packaging Materials. Open J. Org. Polym. Mater. 2016, 6, 11-24. https://doi.org/10.4236/ojopm.2016.61002

Dai, H.; Chang, P.R.; Yu, J.; Ma, X. N,N-Bis(2-hydroxyethyl)formamide as a New Plasticizer for Thermoplastic Starch. Starch 2008, 60, 676-684. https://doi.org/10.1002/star.200800017

Klinsoda, J. Edible coating and film for vegetables and fruits. Food J. 2016, 46, 33-37.

Fan. W.; Sun, J.; Chen, Y.; Zhang, Y.; Chi, Y. Effect of chitosan coating on quality and shelf life of silver carp during frozen storage. Food Chem. 2009, 115, 66-70. https://doi.org/10.1016/j.foodchem.2008.11.060

Suman, S.P.; Mancini, R.A.; Joseph, P.; Ramanathan, R.; Konda, M.K.R.; Dady, G.; Yin, S. Packaging-specific influence of chitosan on color stability and lipid oxidation in refrigerated ground beef. Meat Sci. 2010, 86, 994-998. https://doi.org/10.1016/j.meatsci.2010.08.006

Petrou, S.; Tsiraki, M.; Giatrakou, V.; Savvaidis, I.N. Chitosan dipping or oregano oil treatments, singly or combined on modified atmosphere packaged chicken breast meat. Int. J. Food Microbiol. 2012, 156, 264-271. https://doi.org/10.1016/j.ijfoodmicro.2012.04.002

Imsombut, T.; Tansupo, P.; Pholhan, D. Preparation and characterization of chitosan/silk sericin blend films for use as drug delivery. Research report 2014, pp. 5-8.

Tapia-Blácido, D.; Sobral, P.J.A.; Menegalli, F.C. Development and characterization of edible films based on amaranth flour (Amaranthus caudatus). J. Food Eng. 2005, 67, 215-223. https://doi.org/10.1016/j.jfoodeng.2004.05.054

Bajić, M.; Ročnik, T.; Oberlintner, A.; Scognamiglio, F.; Novak, U.; Likozar, B. Natural plant extracts as active components in chitosan-based films: A comparative study. Food Packaging Shelf. 2019, 21, 100365. https://doi.org/10.1016/j.fpsl.2019.100365

Wrońska, N.; Katir, N.; Nowak-Lange, M.; El Kadib, A.; Lisowska, K. Biodegradable chitosan-based films as an alternative to plastic packaging. Foods. 2023, 12, 3519. https://doi.org/10.3390/foods12183519

Nguyen, T.T.; Pham, B-T.T.; Le, H.N.; Bach, L.G.; Thuc, C.N.H. Comparative characterization and release study of edible films of chitosan and natural extracts. Food Packaging Shelf. 2022, 32, 100830. https://doi.org/10.1016/j.fpsl.2022.100830

De Carli, C.; Aylanc, V.; Mouffok, K.M.; Santamaria-Echart, A.; Barreiro, F.; Tomás, A.; Pereira, C.; Rodrigues, P.; Vilas-Boas, M.; Falcão, S.I. Production of chitosan-based biodegradable active films using bio-waste enriched with polyphenol propolis extract envisaging food packaging applications. Int. J. Biol. Macromol. 2022, 213, 486-497. https://doi.org/10.1016/j.ijbiomac.2022.05.155

Kamdem, D.P.; Shen, Z.; Nabinejad, O.; Shu, Z. Development of biodegradable composite chitosan-based films incorporated with xylan and carvacrol for food packaging application. Food Packaging Shelf. 2019, 21, 100344. https://doi.org/10.1016/j.fpsl.2019.100344

Zehra, A.; Wani, S.M.; Jan, N.; Bhat, T.A.; Rather, S.A.; Malik, A.R.; Hussain, S.Z. Development of chitosan based biodegradable films enriched with thyme essential oil and additives for potential applications in packaging of fresh collard greens. Sci. Rep. 2022, 12, 16923. https://doi.org/10.1038/s41598-022-20751-1

Bhargavi, U.; Keerthi, S.; Behera, P.; Sushmitha, M.; Padma, M. Development of biodegradable film from chitosan and lemongrass essential oil for food packaging applications. Indian J. Ecol. 2023, 50, 1563-1568.

Khwaldia K.; Arab-Tehrany, E.; Desobry, S. Biopotymer coatings on paper packaging materials. Compr. Rev. Food Sci. Food Saf. 2010, 9, 82-91. https://doi.org/10.1111/j.1541-4337.2009.00095.x

AOAC. Official Methods of Analysis, 17th Ed.; The Association of Official Analytical Chemists, Gaithersburg, MD, USA. 2000.

Bourtoom, T. Plasticizer effect on the properties of biodegradable blend film from rice starch-chitosan. Songklanakarin J. Sci. Technol. 2008. 30, 149-165.

Bourtoom, T.; Chinan M.S. Preparation and properties of rice starch-chitosan blend biodegradable film. LWT - Food Sci. Technol. 2008, 41, 1633-1641. https://doi.org/10.1016/j.lwt.2007.10.014

ASTM. Standard Test Methods for Tensile Properties of Thin Plastic Sheeting, Method D882-00; American Society for Testing and Materials, Philadelphia, 2000.

The Technical Association of the Pulp and Paper Industry (TAPPI). Thickness (caliper) of paper, paperboard, and combined board, T411-om97, Georgia, 1997.

The Technical Association of the Pulp and Paper Industry (TAPPI). Water absorptiveness of sized (non-bibulous) paper, paperboard, and corrugated fiberboard (Cobb test), T411-om09, Georgia, 2013.

Roberts, G. A. F. Chitosan production routes and their role in determining the structure and properties of the product.- In Proceedings of International conference; 7th, Chitin and chitosan. Lyon. France. 1st January 1997. Domard, A., Roberts, G. A. F., Varum, K. M. (Eds.). Publisher: Jacques Andre, 1997.

Liu, L. Bioplastics in food packaging: Innovative technologies for biodegradable packaging. San Jose State University Packaging Engineering 2006, 13, 1348-1368.

Chillo, S.; Flores, S.; Mastromatteo, M.; Conte, A.; Gerschenson, L.; Del Nobile, M.A. Influence of glycerol and chitosan on tapioca starch-based edible film properties. J. Food Eng. 2008, 88, 159-168. https://doi.org/10.1016/j.jfoodeng.2008.02.002

Selleh, E.; Muhamad, I.I.; Khairuddin, N. Structural Characterization and Physical Properties of Antimicrobial (AM) Starch-Based Films. World Academy of Science, Engineering and Technology, International Journal of Biological, Biomolecular, Agricultural, Food and Biotechnological Engineering 2009, 3, 352-360.

Vartiainen, J.; Harlin, A. Crosslink as an Efficient Tool for Decreasing Moisture Sensitivity of Biobased Nanocomposite Films. Materials Sciences and Applications 2011, 2, 346-354. https://doi.org/10.4236/msa.2011.25045