Influence of Molding Condition and Moisture Content of Arecanut Leaf Sheath on Quality of Food Plates

Main Article Content

Abstract

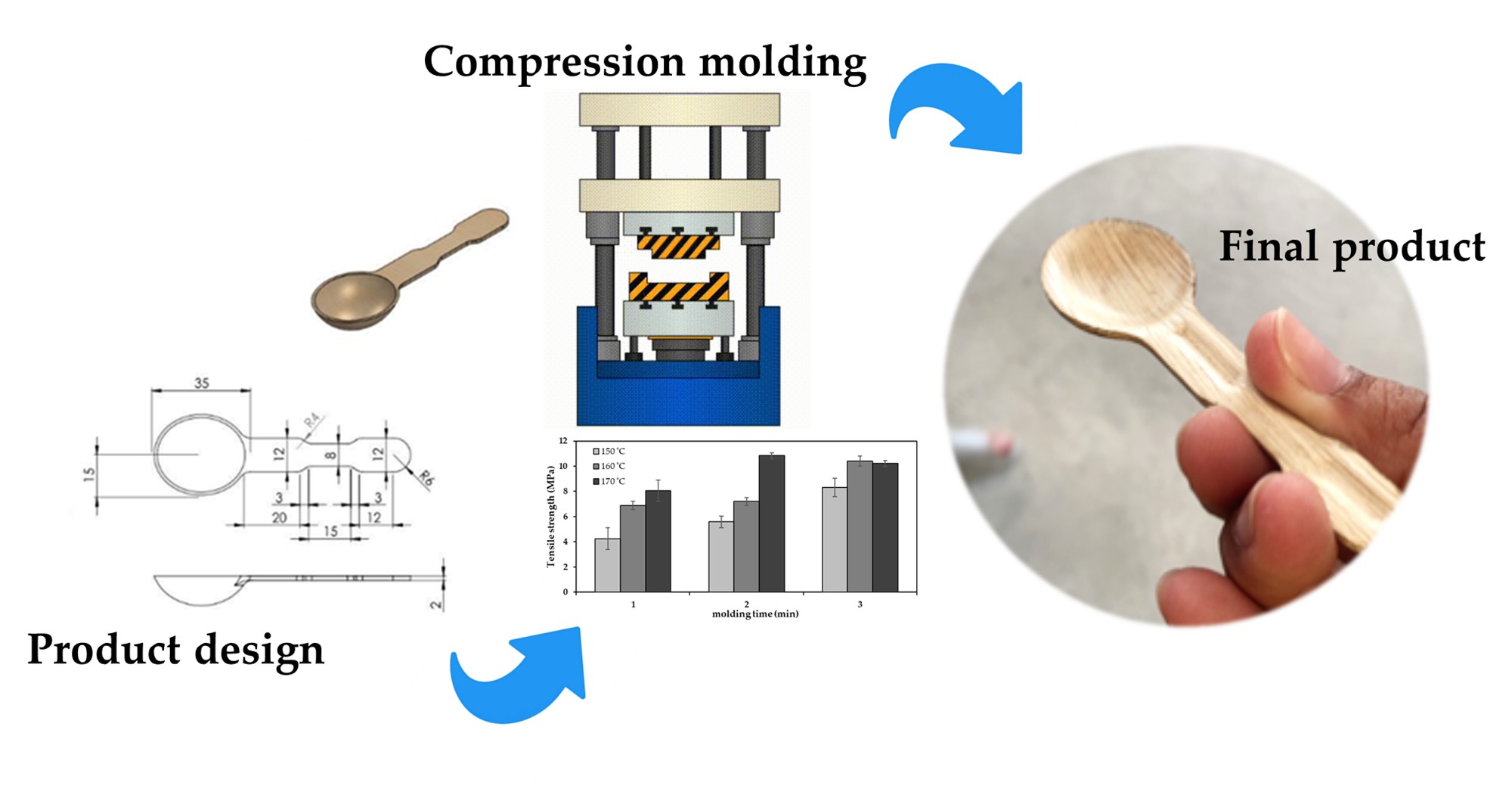

This research focuses on the molding conditions for producing areca nut leaf sheath-based food plates. Food plate samples from the Arecanut leaf sheath were prepared using compression molding. The molding temperature varied at 150, 160, and 170 °C, and the molding time was 1, 2, and 3 min. The quality of the obtained plates was assessed based on their physical appearance. Increasing the molding temperature and molding time obtained smoother and more beautiful surfaces. However, the most suitable molding condition was a temperature of 170 °C for 2 min. The moisture content of areca nuts before molding should be in the range of 20–60 wt.%. The research findings will assist those looking to produce food packaging from the arecanut leaf sheath by providing insights into their components and optimal molding conditions. This will streamline the process, reducing the time spent studying molding conditions and minimizing production waste.

Article Details

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

References

Mangaraj, S.; Yadav, A.; Bal, L. M.; Dash, S. K.; Mahanti, N. K. Application of biodegradable polymers in food packaging industry: A comprehensive review. Journal of Packaging Technology and Research 2019, 3, 77-96.

Han, J. W.; Ruiz‐Garcia, L.; Qian, J. P.; Yang, X. T. Food packaging: A comprehensive review and future trends. Comprehensive Reviews in Food Science and Food Safety 2018, 17, 860-877.

Nielsen, T. D.; Holmberg, K.; Stripple, J. Need a bag? A review of public policies on plastic carrier bags–Where, how and to what effect?. Waste management 2019, 87, 428-440.

Lascurain, M.; López-Binnqüist, C.; Avendaño, S.; Covarrubias, M. The plants leaves used to wrap tamales in the Mexican state of Veracruz. Economic Botany 2017, 71, 374-379.

Mensah, J. K.; Adei, E.; Adei, D.; Ashie, M. D. Perceptions of the use of indigenous leaves as packaging materials in the ready-to-eat cornmeals. International Journal of Biological and Chemical Sciences 2012, 6, 1051-1068.

Ng, C. Plant leaves in food preparation and packaging. UTAR Agriculture Science Journal (UASJ) 2015, 1, 34-39.

Onzo, F. C.; Azokpota, P.; Akissoe, N.; Agbani, O. P. Biodiversité des emballages-feuilles végétales utilisées dans l’artisanat agroalimentaire au Sud du Bénin. Journal of Applied Biosciences 2013, 72, 5810-5821.

Mustafa, M.; Nagalingam, S.; Tye, J.; Shafii, A. H.; Dolah, J. Looking back to the past: revival of traditional food packaging. In 2nd Regional Conference on Local Knowledge (KEARIFAN TEMPATAN) 2012, 1, 1-17.

Poddar, P.; Islam, M. S.; Sultana, S.; Nur, H. P.; Chowdhury, A. M. S. Mechanical and thermal properties of short arecanut leaf sheath fiber reinforced polypropyline composites: TGA, DSC and SEM analysis. J Material Sci Eng 2018, 5, 2169-0022.

Yinghuai, Z.; Yuanting, K. T.; Hosmane, N. S. Applications of ionic liquids in lignin chemistry. Ionic Liquids—New Aspects for the Future; IntechOpen: London, UK, 2013, 315-346.

Kirk, T. K.; Farrell, R. L. Enzymatic" combustion": the microbial degradation of lignin. Annual Reviews in Microbiology 1987, 41, 465-501.

Cathala, B.; Saake, B.; Faix, O.; Monties, B. Evaluation of the reproducibility of the synthesis of dehydrogenation polymer models of lignin. Polymer degradation and stability 1998, 59, 65-69.

Patel, J. P.; Parsania, P. H. Characterization, testing, and reinforcing materials of biodegradable composites. Biodegradable and Biocompatible Polymer Composites: Processing, Properties and Applications; Woodhead Publishing is an imprint of Elsevier: Duxford, UK, 2017, 55-78.