The Approach for Boosting the Drying Chamber's Temperature by Pulse Copper Pipes to Conduct Heat

Main Article Content

Abstract

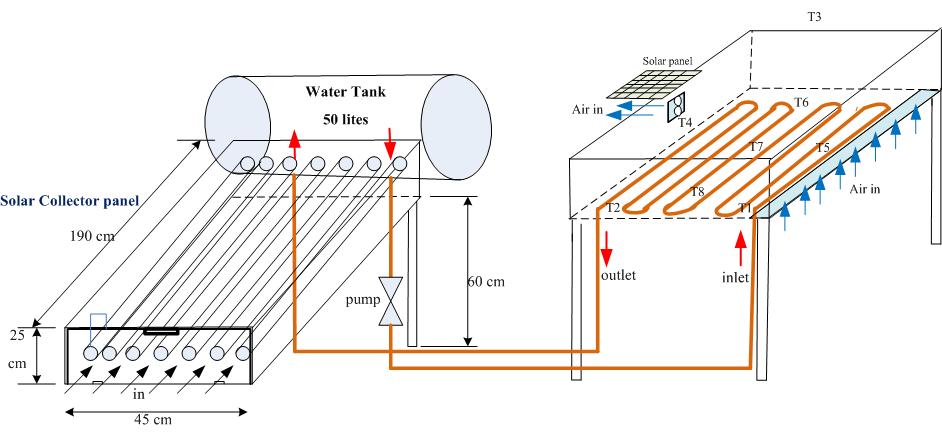

This research addresses a critical challenge in solar food drying: maintaining effective drying performance during low solar radiation intensity periods. We present an innovative hybrid drying system that combines thermal energy from direct solar radiation with supplementary heat provided by hot water circulating through strategically positioned copper pipes. The pulse copper pipe configuration conducts additional heat within the drying chamber, significantly enhancing thermal performance when outdoor temperatures drop or sunlight is limited. Experimental results demonstrate that this hybrid approach increases the temperature inside the drying chamber and extends drying periods by at least 10 minutes under low heat radiation conditions. Most notably, the combination of air drying with infrared radiation and hot water circulation yielded a 4.25% improvement in thermal efficiency compared to conventional methods. This approach represents a promising advancement in sustainable food preservation technology, particularly for regions with variable weather conditions.

Article Details

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

References

Phoosomma, P. Construction and Efficiency Test of Solar Drying Cabinet for Nipa Palm Drying for Community Enterprise. In Proceedings of the 18th International Conference on Control, Automation and Systems (ICCAS), PyeongChang, South Korea, 17-20 October 2018; pp. 1414-1417.

Korbuakaew, K.; Phoosomma, P. Prototype a Food Processing Combination Heated Drying Cabinet. In Proceedings of the 37th International Technical Conference on Circuits/Systems, Computers and Communications (ITC-CSCC), Phuket, Thailand, 4-7 July 2022; pp. 1-4. https://doi.org/10.1109/ITC-CSCC55581.2022.9894865

Vengsungnle, P.; Jongpluempiti, J.; Srichat, A.; Wiriyasart, S.; Naphon, P. Thermal performance of the photovoltaic–ventilated mixed mode greenhouse solar dryer with automatic closed loop control for Ganoderma drying. Case Stud. Therm. Eng. 2020, 21, 100659. https://doi.org/10.1016/j.csite.2020.100659

Nain, S.; Ahlawat, V.; Kajal, S.; Anuradha, P.; Sharma, A.; Singh, T. Performance analysis of different U-shaped heat exchangers in parabolic trough solar collector for air heating applications. Case Stud. Therm. Eng. 2021, 25, 100949. https://doi.org/10.1016/j.csite.2021.100949

Amiri, S.; Gorji, B.; Bandpy, M.; Jahanshahi, M. Drying behaviour of lemon balm leaves in an indirect double-pass packed bed forced convection solar dryer system. Case Stud. Therm. Eng. 2018, 12, 677-686. https://doi.org/10.1016/j.csite.2018.08.007

Fadhil, A.; Jalil, J.; Bilal, G. Experimental and numerical investigation of solar air collector with phase change material in column obstruction. J. Energy Storage 2024, 79, 110066. https://doi.org/10.1016/j.est.2023.110066

Sharma, M.; Atheaya, D.; Kumar, A. Performance evaluation of indirect type domestic hybrid solar dryer for tomato drying: Thermal, embodied, economical and quality analysis. Therm. Sci. Eng. Prog. 2023, 42, 101882. https://doi.org/10.1016/j.tsep.2023.101882

Chouicha, S.; Boubekri, A.; Mennouche, D.; Berrbeuh, M.H. Solar Drying of Sliced Potatoes an Experimental Investigation. Energy Procedia 2013, 36, 1276-1285. https://doi.org/10.1016/j.egypro.2013.07.144

GaneshKumar, P.; Sundaram, P.; Sathishkumar, A.; Vigneswaran, V.S.; Chopra, T.; Thakur, U.; Kim, S.; Ramkumar, V. Exploring the performance of an indirect solar dryer by combining three augmentation approaches (trapezoidal absorber, shot blasting, and pebble stone). J. Energy Storage 2024, 78, 110109. https://doi.org/10.1016/j.est.2023.110109

Murthy, M.V.R. A review of new technologies, models and experimental investigations of solar driers. Renew. Sustain. Energy Rev. 2009, 13, 835-844. https://doi.org/10.1016/j.rser.2008.02.010

Gautam, A.; Chamoli, S.; Kumar, A.; Singh, S. A review on technical improvements, economic feasibility and world scenario of solar water heating system. Renew. Sustain. Energy Rev. 2017, 68, 541-562. https://doi.org/10.1016/j.rser.2016.09.104

Bernardo, L.; Davidsson, H.; Karlsson, B. Retrofitting Domestic Hot Water Heaters for Solar Water Heating Systems in Single-Family Houses in a Cold Climate: A Theoretical Analysis. Energies 2012, 5, 4110-4131. https://doi.org/10.3390/en5104110

Koua, K.; Fassinou, W.; Prosper Gbaha, P.; Siaka Toure, S. Mathematical modelling of the thin layer solar drying of banana, mango and cassava. Energy 2009, 34, 1594-1602. https://doi.org/10.1016/j.energy.2009.07.005

Ismail, M.A.; Idriss, E.M.I. Mathematical modelling of thin layer solar drying of whole okra (Abelmoschus esculentus (L.) Moench) pods. Int. Food Res. J. 2013, 20, 1983-1989.

Heydari, A. Experimental analysis of hybrid dryer combined with spiral solar air heater and auxiliary heating system: Energy, exergy and economic analysis. Renew. Energy 2022, 198, 1162-1175. https://doi.org/10.1016/j.renene.2022.08.110

Yang, H.; Wang, J.; Wang, N.; Yang, F. Experimental study on a pulsating heat pipe heat exchanger for energy saving in air-conditioning system in summer. Energy Build. 2019, 197, 1-6. https://doi.org/10.1016/j.enbuild.2019.05.032

Bastakoti, D.; Zhang, H.; Li, D.; Cai, W.; Li, F. An overview on the developing trend of pulsating heat pipe and its performance. Appl. Therm. Eng. 2018, 141, 305-332. https://doi.org/10.1016/j.applthermaleng.2018.05.121

Barba, M.; Bruce, R.; Bouchet, F.; Bonelli, A.; Baudouy, B. Effects of filling ratio of a long cryogenic Pulsating Heat Pipe. Appl. Therm. Eng. 2023, 194, 117072. https://doi.org/10.1016/j.applthermaleng.2021.117072

Nikolayev, V. Physical principles and state-of-the-art of modeling of the pulsating heat pipe: A review. Appl. Therm. Eng. 2021, 195, 117111. https://doi.org/10.1016/j.applthermaleng.2021.117111

Li, Z.; Sarafraz, M.M.; Mazinani, A.; Moria, H.; Iskander Tlili, I.; Tawfeeq Alkanhal, T.; Goodarzi, M.; Safaei, M. Operation analysis, response and performance evaluation of a pulsating heat pipe for low temperature heat recovery. Energy Convers. Manag. 2020, 222, 113230. https://doi.org/10.1016/j.enconman.2020.113230

Nazari, M.A.; Ahmadi, M.H.; Ghasempour, R.; Shafii, M.B.; Mahian, O.; Kalogirou, S.; Wongwises, S. A review on pulsating heat pipes: From solar to cryogenic applications. Appl. Energy 2018, 222, 475-484. https://doi.org/10.1016/j.apenergy.2018.04.020

Nikolayev, V. Effect of tube heat conduction on the single branch pulsating heat pipe start-up. Int. J. Heat Mass Transf. 2016, 95, 477-487. https://doi.org/10.1016/j.ijheatmasstransfer.2015.12.016

Jo, J.; Kim, J.; Kim, S. Experimental investigations of heat transfer mechanisms of a pulsating heat pipe. Energy Convers. Manag. 2019, 181, 331-341. https://doi.org/10.1016/j.enconman.2018.12.027

Kumar, N.; Tripathi, M.M. Design of a Novel Solar Energy Market Model for Indian Scenario. J. Electr. Eng. Technol. 2021, 16, 2783–2792. https://doi.org/10.1007/s42835-021-00802-9

Alsharif, M.; Yahya, K.; Geem, Z. Strategic Market Growth and Policy Recommendations for Sustainable Solar Energy Deployment in South Korea. J. Electr. Eng. Technol. 2020, 15, 803-815. https://doi.org/10.1007/s42835-019-00331-6

Davidsson, H.; Bernardo, R.; Hellström, B. Hybrid Ventilation with Innovative Heat Recovery-A System Analysis. Buildings 2013, 3, 245-257. https://doi.org/10.3390/buildings3010245

Mohamed, I.; Idriss, E.M. Mathematical modelling of thin layer solar drying of whole okra (Abelmoschus esculentus (L.) Moench) pods. Int. Food Res. J. 2013, 20, 1983-1989.

Chouicha, S.; Boubekri, A.; Mennouche, D.; Berrbeuh, M. Solar Drying of Sliced Potatoes. An Experimental Investigation. Energy Procedia 2013, 36, 1276-1285. https://doi.org/10.1016/j.egypro.2013.07.144

Nazari, M.; Ahmadi, M.; Ghasempour, R.; Shafii, M.; Mahian, O.; Kalogirou, S.; Wongwises, S. A review on pulsating heat pipes: From solar to cryogenic applications. Appl. Energy 2018, 222, 475-484. https://doi.org/10.1016/j.apenergy.2018.04.020