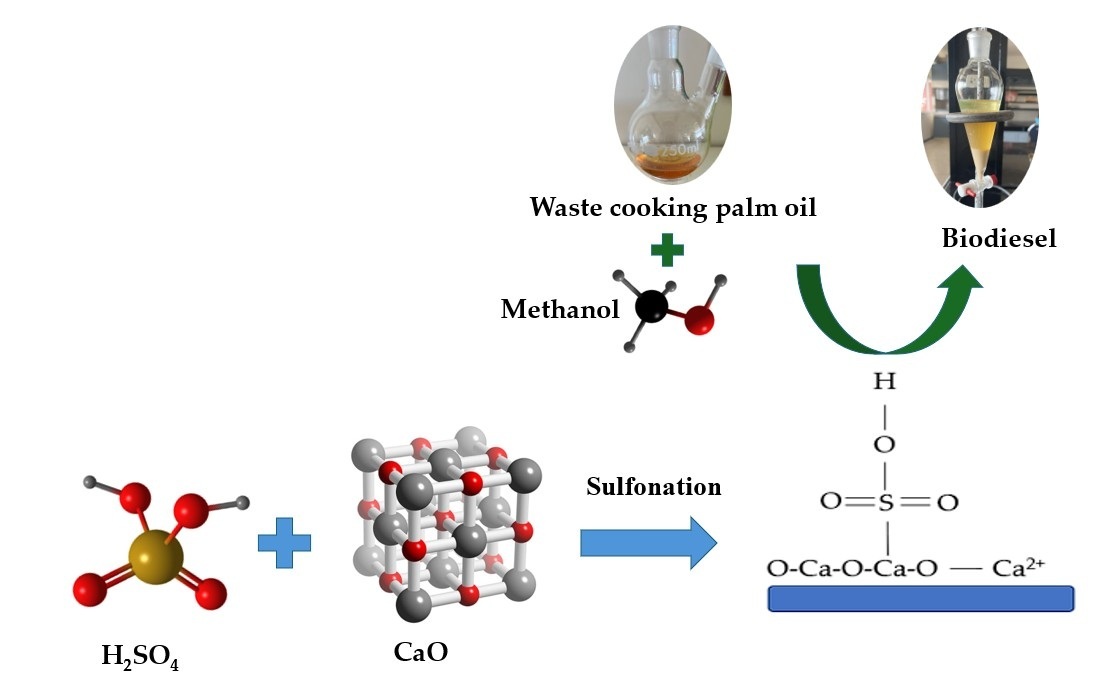

Preparation and Characterization of Sulfonated CaO Catalyst for Biodiesel Production from Waste Cooking Oil

Main Article Content

Abstract

Biodiesel production depends on raw materials. Low-quality oils, such as cooking oil, crude palm oil, and sludge oil, are used to reduce costs, and they contain free fatty acids (FFA) and water. Soap can be produced when using the alkaline catalyst during transesterification. In this work, the sulfonation method prepared the esterification of waste cooking oil by sulfonated CaO as a bifunctional catalyst. The sulfonated CaO catalysts were characterized by X-ray diffraction spectroscopy (XRD), Fourier transform infrared spectroscopy (FTIR), temperature-programmed desorption of carbon dioxide and ammonia (TPD), BET surface area, and scanning electron microscopy (SEM). It was observed that the specific surface area, pore volume, and pore diameter of the CaO increased after being sulfonated with a 2 M sulfuric acid solution. It showed a high total surface acidity and basicity, 7.22 and 3.86 mmol/g, respectively. The optimal FFA conversion (84.94 %) from the waste cooking oil was acquired at a reaction temperature of 65 ˚C, a 9:1 MeOH: Oil molar ratio, and 5 wt% catalyst loading for a 3 h reaction time. The 2 M sulfonated CaO catalyst can be reused twice with a high FFA conversion without further treatment under optimized reaction conditions. The 2 M sulfonated CaO catalyst has potential treatment for biodiesel production from high-FFA oils due to its lower production cost and high catalytic activity.

Article Details

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

References

Farabi, M. S. A.; Ibrahim, M. L.; Rashid, U.; Taufiq-Yap, Y. H. Esterification of palm fatty acid distillate using sulfonated carbon-based catalyst derived from palm kernel shell and bamboo. Energy Conversion and Management 2019, 181(September 2018), 562–570. https://doi.org/10.1016/j.enconman.2018.12.033

Amenaghawon, A. N.; Obahiagbon, K.; Isesele, V.; Usman, F. Optimized biodiesel production from waste cooking oil using a functionalized bio-based heterogeneous catalyst. Cleaner Engineering and Technology 2022, 8(April), 1-11. 100501. https://doi.org/10.1016/j.clet.2022.100501

Baskar, G.; Kalavathy, G.; Aiswarya, R.; Abarnaebenezer Selvakumari, I. Advances in bio-oil extraction from nonedible oil seeds and algal biomass. In Advances in Eco-Fuels for a Sustainable Environment 2019, 187–210. Elsevier. https://doi.org/10.1016/B978-0-08-102728-8.00007-3

Okoduwa, I. G.; Oiwoh, O.; Amenaghawon, A. N.; Okieimen, C. O. A biobased mixed metal oxide catalyst for biodiesel production from waste cooking oil: reaction conditions modeling, optimization and sensitivity analysis study. Journal of Engineering Research (Kuwait) 2024, February. https://doi.org/10.1016/j.jer.2024.03.009

Deeba, F.; Kumar, B.; Arora, N.; Singh, S.; Kumar, A.; Han, S. S.; Negi, Y. S. Novel bio-based solid acid catalyst derived from waste yeast residue for biodiesel production. Renewable Energy 2020, 159, 127–139. https://doi.org/10.1016/j.renene.2020.05.029

Chanakaewsomboon, I.; Tongurai, C.; Photaworn, S.; Kungsanant, S.; Nikhom, R. Investigation of saponification mechanisms in biodiesel production: Microscopic visualization of the effects of FFA, water and the amount of alkaline catalyst. Journal of Environmental Chemical Engineering 2020, 8(2), 1-40. https://doi.org/10.1016/j.jece.2019.103538

Etim, A. O.; Musonge, P.; Eloka-Eboka, A. C. An effective green and renewable heterogeneous catalyst derived from the fusion of bi-component biowaste materials for the optimized transesterification of linseed oil methyl ester. Biofuels, Bioproducts and Biorefining 2021, 15(5), 1461–1472. https://doi.org/10.1002/bbb.2252

Kedir, W. M.; Wondimu, K. T.; Weldegrum, G. S. Optimization and characterization of biodiesel from waste cooking oil using modified CaO catalyst derived from snail shell. Heliyon 2023, 9(5), e16475. https://doi.org/10.1016/j.heliyon.2023.e16475

Faruque, M. O.; Razzak, S. A.; Hossain, M. M. Application of heterogeneous catalysts for biodiesel production from microalgal oil—a review. Catalysts 2020, 10(9), 1–25. https://doi.org/10.3390/catal10091025

Al-Saadi, A.; Mathan, B.; He, Y. Biodiesel production via simultaneous transesterification and esterification reactions over SrO–ZnO/Al2O3 as a bifunctional catalyst using high acidic waste cooking oil. Chemical Engineering Research and Design 2020, 162(2018), 238–248. https://doi.org/10.1016/j.cherd.2020.08.018

Chen, G. Y.; Shan, R.; Yan, B. B.; Shi, J. F.; Li, S. Y.; Liu, C. Y. Remarkably enhancing the biodiesel yield from palm oil upon abalone shell-derived CaO catalysts treated by ethanol. Fuel Processing Technology, 2016, 143, 110–117. https://doi.org/10.1016/j.fuproc.2015.11.017

Istadi, I.; Anggoro, D. D.; Buchori, L.; Rahmawati, D. A.; Intaningrum, D. Active acid catalyst of sulphated zinc oxide for transesterification of soybean oil with methanol to biodiesel. Procedia Environmental Sciences 2015, 23, 385–393. https://doi.org/10.1016/j.proenv.2015.01.055

Syazwani, O. N.; Rashid, U.; Mastuli, M. S.; Taufiq-Yap, Y. H. Esterification of palm fatty acid distillate (PFAD) to biodiesel using Bi-functional catalyst synthesized from waste angel wing shell (Cyrtopleura costata). Renewable Energy 2019, 131, 187–196. https://doi.org/10.1016/j.renene.2018.07.031

Syazwani, O. N.; Ibrahim, M. L.; Wahyudiono, Kanda, H.; Goto, M.; Taufiq-Yap, Y. H. Esterification of high free fatty acids in supercritical methanol using sulfated angel wing shells as catalyst. Journal of Supercritical Fluids 2017, 124, 1–9. https://doi.org/10.1016/j.supflu.2017.01.002

Valizadeh, S.; Valizadeh, B.; Khani, Y.; Jae, J.; Hyun Ko, C.; Park, Y. K. Production of biodiesel via esterification of coffee waste-derived bio-oil using sulfonated catalysts. Bioresource Technology 2024, 404(May), 130908. https://doi.org/10.1016/j.biortech.2024.130908

Kouzu, M.; Kasuno, T.; Tajika, M.; Sugimoto, Y.; Yamanaka, S.; Hidaka, J. Calcium oxide as a solid base catalyst for transesterification of soybean oil and its application to biodiesel production. Fuel 2008, 87(12), 2798–2806. https://doi.org/10.1016/j.fuel.2007.10.019

Kiefer, J.; Strk, A.; Kiefer, A. L.; Glade, H. Infrared spectroscopic analysis of the inorganic deposits from water in domestic and technical heat exchangers. Energies 2018, 11(4). https://doi.org/10.3390/en11040798

Juan-Alcañiz, J.; Gielisse, R.; Lago, A.B.; Ramos-Fernandez, E.V.; Serra-Crespo, P.; Devic, T.; Guillou, N. Serre, C.; Kapteijna, F.; Gascon; J. Towards acid MOFs-catalytic performance of sulfonic acid functionalized architectures. Catalysis Science & Technology 2013, 3(9), 2311–2318, https://doi.org/10.1039/c3cy00272a

Nayebzadeh, H.; Hojjat, M. Fabrication of SO42−/MO–Al2O3–ZrO2 (M = Ca, Mg, Sr, Ba) as solid acid–base nanocatalyst used in trans/esterification reaction. Waste and Biomass Valorization, 2020, 11(5), 2027–2037. https://doi.org/10.1007/s12649-018-0526-0

Liu, F.; Ma, X.; Li, H.; Wang, Y.; Cui, P.; Guo, M.; Yaxin, H.; Lu, W.; Zhou, S.; Yu, M. Dilute sulfonic acid post functionalized metal organic framework as a heterogeneous acid catalyst for esterification to produce biodiesel. Fuel, 2020, 266(January), 117149. https://doi.org/10.1016/j.fuel.2020.117149

Hussein, A. I.; Ab-Ghani, Z.; Mat, A. N. C.; Ghani, N. A. A.; Husein, A.; Rahman, I. A. Synthesis and characterization of spherical calcium carbonate nanoparticles derived from cockle shells. Applied Sciences (Switzerland) 2020, 10(20), 1–14. https://doi.org/10.3390/app10207170

Farabi, M. S. A.; Ibrahim, M. L.; Rashid, U., Taufiq-Yap, Y. H. Esterification of palm fatty acid distillate using sulfonated carbon-based catalyst derived from palm kernel shell and bamboo. Energy Conversion and Management 2019, 181(September), 562–570. https://doi.org/10.1016/j.enconman.2018.12.033

Xiong, X.; Yu, I. K. M.; Chen, S. S.; Tsang, D. C. W.; Cao, L.; Song, H.; Kwon, E. E.; Ok, Y. S.; Zhang, S.; Poon, C. S. Sulfonated biochar as acid catalyst for sugar hydrolysis and dehydration. Catalysis Today 2018, 314(February), 52–61. https://doi.org/10.1016/j.cattod.2018.02.034

Melo H. P.; Cruz, A. J.; Candeias, A.; Mirão, J.; Cardoso, A. M.; Oliveira, M. J.; Valadas, S. Problems of analysis by FTIR of calcium sulphate-based preparatory layers: The case of a group of 16th-century Portuguese paintings. Archaeometry 2014, 56(3), 513–526. https://doi.org/10.1111/arcm.12026

Tangboriboon, N.; Unjan, W.; Sangwan, W.; Sirivat, A. Preparation of anhydrite from eggshell via pyrolysis. Green Processing and Synthesis 2018, 7(2), 139–146. https://doi.org/10.1515/gps-2016-0159

McQuillan, A. J.; Osawa, M.; Peak, D.; Ren, B.; Tian, Z. Q. Experiments on adsorption at hydrous metal oxide surfaces using attenuated total reflection infrared spectroscopy (ATRIRS) (IUPAC Technical Report). Pure and Applied Chemistry, 2019, 91(12), 2043–2061. https://doi.org/10.1515/pac-2019-0211

Ali, R. M.; Abd El Latif, M. M; Farag, H. A. Preparation and characterization of CaSO4–SiO2–CaO/SO42- composite for biodiesel production. American Journal of Applied Chemistry 2015, 3(3-1), 38-45. https://doi.org/10.11648/j.ajac.s.2015030301.16.

Zhu, Z.; Liu, Y.; Cong, W.; Zhao, X.; Janaun, J.; Wei, T.; Fang, Z. Soybean biodiesel production using synergistic CaO/Ag nano catalyst: Process optimization, kinetic study, and economic evaluation. Industrial Crops and Products 2021, 166(666), 113479. https://doi.org/10.1016/j.indcrop.2021.113479

Shi, G.; Yu, F.; Wang, Y.; Pan, D.; Wang, H.; Li, R. A novel one-pot synthesis of tetragonal sulfated zirconia catalyst with high activity for biodiesel production from the transesterification of soybean oil. Renewable Energy 2016, 92, 22–29. https://doi.org/10.1016/j.renene.2016.01.094

Zhang, G.; Cao, D.; Wang, X.; Guo, S.; Yang, Z.; Cui, P.; Wang, Q.; Dou, Y.; Cheng, S.; Shen, H. α-calcium sulfate hemihydrate with a 3D hierarchical straw-sheaf morphology for use as a remove Pb2+ adsorbent. Chemosphere 2022, 287. https://doi.org/10.1016/j.chemosphere.2021.132025

Marchetti, J. M.; Pedernera, M. N.; Schbib, N. S. Production of biodiesel from acid oil using sulfuric acid as catalyst: Kinetics study. International Journal of Low-Carbon Technologies 2011, 6(1), 38–43. https://doi.org/10.1093/ijlct/ctq040

Ganesan, S.; Nadarajah, S.; Chee, X. Y.; Khairuddean, M.; Teh, G. B. Esterification of free fatty acids using ammonium ferric sulphate-calcium silicate as a heterogeneous catalyst. Renewable Energy 2020, 153, 1406–1417. https://doi.org/10.1016/j.renene.2020.02.094

Sunarno, Zahrina, I.; Reni Yenti, S.; Sri Irianty, R.; Setia Utama, P. Catalytic co-pyrolysis of palm oil empty fruit bunch and waste tire using calcium oxide catalysts for upgrading bio-oil. Materials Today: Proceedings 2023, 87, 321–326. https://doi.org/10.1016/j.matpr.2023.03.290

Lani, N. S.; Ngadi, N.; Yahya, N. Y.; Rahman, R. A. Synthesis, characterization and performance of silica impregnated calcium oxide as heterogeneous catalyst in biodiesel production. Journal of Cleaner Production 2017, 146, 116–124. https://doi.org/10.1016/j.jclepro.2016.06.058

Farooq, M.; Ramli, A.; Subbarao, D. Biodiesel production from waste cooking oil using bifunctional heterogeneous solid catalysts. Journal of Cleaner Production 2013, 59, 131–140. https://doi.org/10.1016 /j.jclepro.2013.06.015

Safakish, E.; Nayebzadeh, H.; Saghatoleslami, N.; Kazemifard, S. Comprehensive assessment of the preparation conditions of a separable magnetic nanocatalyst for biodiesel production from algae. Algal Research 2020, 49(May), 101949. https://doi.org/10.1016/j.algal.2020.101949

Jamil, F.; Murphin Kumar, P. S.; Al-Haj, L.; Tay Zar Myint, M.; Al-Muhtaseb, A. H. Heterogeneous carbon-based catalyst modified by alkaline earth metal oxides for biodiesel production: parametric and kinetic study. Energy Conversion and Management: X 2021, 10(May 2020), 100047. 1-10. https://doi.org/10.1016/j.ecmx.2020.100047

Abdelhady, H. H.; Elazab, H. A.; Ewais, E. M.; Saber, M.; El-Deab, M. S. Efficient catalytic production of biodiesel using nano-sized sugar beet agro-industrial waste. Fuel 2020, 261(October 2019), 116481. 1-12. https://doi.org/10.1016/j.fuel.2019.116481

Abbah, E. C.; Nwandikom, G. I.; Egwuonwu, C. C.; Nwakuba, N. R. Effect of reaction temperature on the yield of biodiesel from neem seed oil. American Journal of Energy Science 2016, 3(3), 16–20. http://www.openscienceonline.com/journal/energy

Xie, W.; Wan, F. Basic ionic liquid functionalized magnetically responsive Fe3O4@HKUST-1 composites used for biodiesel production. Fuel 2018, 220(February), 248–256. https://doi.org/10.1016/j.fuel.2018.02.014

Hazmi, B.; Rashid, U.; Ibrahim, M. L.; Nehdi, I. A.; Azam, M.; Al-Resayes, S. I. Synthesis and characterization of bifunctional magnetic nano-catalyst from rice husk for production of biodiesel. Environmental Technology and Innovation 2021, 21, 101296. https://doi.org/10.1016/j.eti.2020.101296

Mokhatr Mohamed, M.; El-Faramawy, H. An innovative nanocatalyst α-Fe2O3/AlOOH processed from gibbsite rubbish ore for efficient biodiesel production via utilizing cottonseed waste oil. Fuel 2021, 297(May 2020), 120741. https://doi.org/10.1016/j.fuel.2021.120741

Xia, S.; Li, J.; Chen, G.; Tao, J.; Li, W.; Zhu, G. Magnetic reusable acid-base bifunctional Co Doped Fe2O3–CaO nanocatalysts for biodiesel production from soybean oil and waste frying oil. Renewable Energy 2022, 189, 421–434. https://doi.org/10.1016/j.renene.2022.02.122

Verma, P.; Sharma, M. P. Review of process parameters for biodiesel production from different feedstocks. Renewable and Sustainable Energy Reviews 2016, 62, 1063–1071. https://doi.org/10.1016/j.rser.2016.04.054

Ruhul, A. M.; Kalam, M. A.; Masjuki, H. H.; Fattah, I. M. R.; Reham, S. S.; Rashed, M. M. State of the art of biodiesel production processes: A review of the heterogeneous catalyst. RSC Advances 2015, 5(122), 101023–101044. https://doi.org/10.1039/c5ra09862a

Giakoumis, E. G. A statistical investigation of biodiesel physical and chemical properties, and their correlation with the degree of unsaturation. Renewable Energy 2013, 50, 858–878. https://doi.org/10.1016/j.renene.2012.07.040

Abdullah, R. F.; Rashid, U.; Ibrahim, M. L.; Hazmi, B.; Alharthi, F. A.; Nehdi, I. A. Bifunctional nano-catalyst produced from palm kernel shell via hydrothermal-assisted carbonization for biodiesel production from waste cooking oil. Renewable and Sustainable Energy Reviews 2021, 137(May 2020), 110638. https://doi.org/10.1016/j.rser.2020.110638

Alam, M. A.; Deng, L.; Ngatcha, A. D. P.; Fouegue, A. D. T.; Wu, J.; Zhang, S.; Zhao, A.; Xiong, W.; Xu, J. Biodiesel production from microalgal biomass by Lewis acidic deep eutectic solvent catalysed direct transesterification. Industrial Crops and Products 2023, 206(May), 117725. https://doi.org/10.1016/j.indcrop.2023.117725