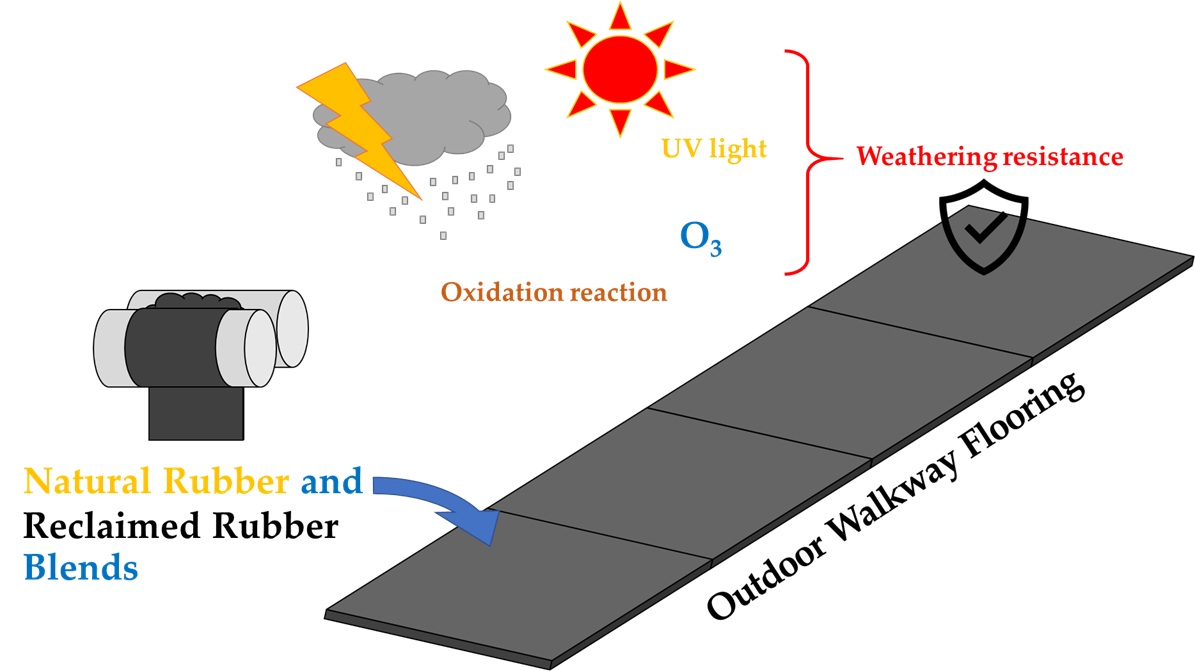

Outdoor Walkway Flooring from Natural Rubber and Reclaimed Rubber Blends with Superior Environmental Resistance

Main Article Content

Abstract

This study systematically investigated the effects of reclaimed rubber (RR) content on the mechanical properties and accelerated aging resistance of natural rubber (NR) vulcanizates for outdoor walkway flooring applications. Six formulations were prepared with NR/RR ratios ranging from 100/0 to 50/100 parts per hundred rubber (phr), maintaining a total rubber content of 100 phr after accounting for the 48-50% actual rubber content in reclaimed rubber (confirmed by thermogravimetric analysis showing 55% mass loss at 350-400°C). Results demonstrated that increasing RR content from 0 to 100 phr progressively decreased tensile strength and elongation at break, while hardness and 300% modulus exhibited slight increases due to residual cross-links and higher filler concentrations in reclaimed rubber. Notably, accelerated aging tests (ASTM D573: 100°C for 22 hours; ASTM G154: UV-A 0.89 W/m² at 340 nm, 60°C for 8 hours, followed by condensation at 50°C for 4 hours, total 168 hours) revealed substantial improvements in aging resistance with increasing RR content. The percentage decrease in tensile strength after aging diminished progressively as RR content increased. The optimized formulation containing 100 phr reclaimed rubber was selected for commercial production. Despite having a relatively lower tensile strength compared to virgin NR formulations, this composition provided adequate mechanical performance while demonstrating superior resistance to environmental degradation. Compression molding at 170°C for 8 minutes produced 1 m² × 0.06 m rubber tiles with anti-slip lozenge patterns. Implementation at a commercial café yielded positive user feedback and achieved an approximately 30% cost reduction compared to virgin rubber formulations, supporting the sustainable utilization of rubber waste.

Article Details

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

References

Mark, J. E. Physical Properties of Polymers Handbook; Springer: New York, 2007.

Puskas, J. E.; Chiang, K.; Barkakaty, B. Natural rubber (NR) biosynthesis: perspectives from polymer chemistry. In Chemistry, Manufacture and Applications of Natural Rubber; K. N. G. S. Ooi, Ed.; Woodhead Publishing, 2014; pp 30–67. https://doi.org/10.1533/9780857096913.1.30

Tessanan, W.; Chanthateyanonth, R.; Yamaguchi, M.; Phinyocheep, P. Improvement of mechanical and impact performance of poly (lactic acid) by renewable modified natural rubber. J. Clean. Prod. 2020, 276, 123800. https://doi.org/10.1016/j.jclepro.2020.123800

Saengdee, L.; Phinyocheep, P.; Daniel, P. Chemical modification of natural rubber in latex stage for improved thermal, oil, ozone and mechanical properties. J. Polym. Res. 2020, 27(275), 1–13. https://doi.org/10.1007/s10965-020-02246-7

Tessanan, W.; Ratvijitvech, T.; Thanawan, S.; Amornsakchai, T.; Phinyocheep, P. Development of waterborne epoxy-based resin incorporated with modified natural rubber latex for coating application. Sci. Rep. 2024, 14 (1), 26603. https://doi.org/10.1038/s41598-024-77990-7

Mao, Z.; Wang, W.; Mao, G. Improving the Thermal Aging Resistance of γ‐Vulcanized Polybutadiene Rubber (BR)/Nature Rubber (NR) Blends with Sulfur Added. Adv. Mater. Sci. Eng. 2021, 2021, 5782539. https://doi.org/10.1155/2021/5782539

Ren, T.; Song, P.; Yang, W.; Formela, K.; Wang, S. Reinforcing and plasticizing effects of reclaimed rubber on the vulcanization and properties of natural rubber. J. Appl. Polym. Sci. 2023, 140(10), e53580. https://doi.org/10.1002/app.53580

Shokoohi, S.; Naderi, G. Natural rubber/natural rubber reclaim nanocomposites: Role of functional nanoparticles, mixing sequences and coupling agents. Polyolefins J. 2021, 8(2), 115–122. https://doi.org/10.22063/poj.2021.2893.1182

Zhang, Y.; Zhang, Z.; Wemyss, A. M.; Wan, C.; Liu, Y.; Song, P.; Wang, S. Effective thermal-oxidative reclamation of waste tire rubbers for producing high-performance rubber composites. ACS Sustainable Chem. Eng. 2020, 8(24), 9079–9087. https://doi.org/10.1021/acssuschemeng.0c02292

Singh, P.; Singh, D. N. Polymer composites from waste plastics and reclaimed rubber from tires for sustainable development. J. Appl. Polym. Sci. 2024, 141(46), e56244. https://doi.org/10.1002/app.56244

Naebpetch, W.; Junhasavasdikul, B.; Saetung, A.; Tulyapitak, T.; Nithi-Uthai, N. Influence of filler type and loading on cure characteristics and vulcanisate properties of SBR compounds with a novel mixed vulcanisation system. Plast. Rubber Compos. 2017, 46(3), 137–145. https://doi.org/10.1080/14658011.2017.1299419.