Manufacturing Design and Cost Analysis for Customer-oriented Rubber Mat Product using Abrasive Waterjet Cutting

Main Article Content

บทคัดย่อ

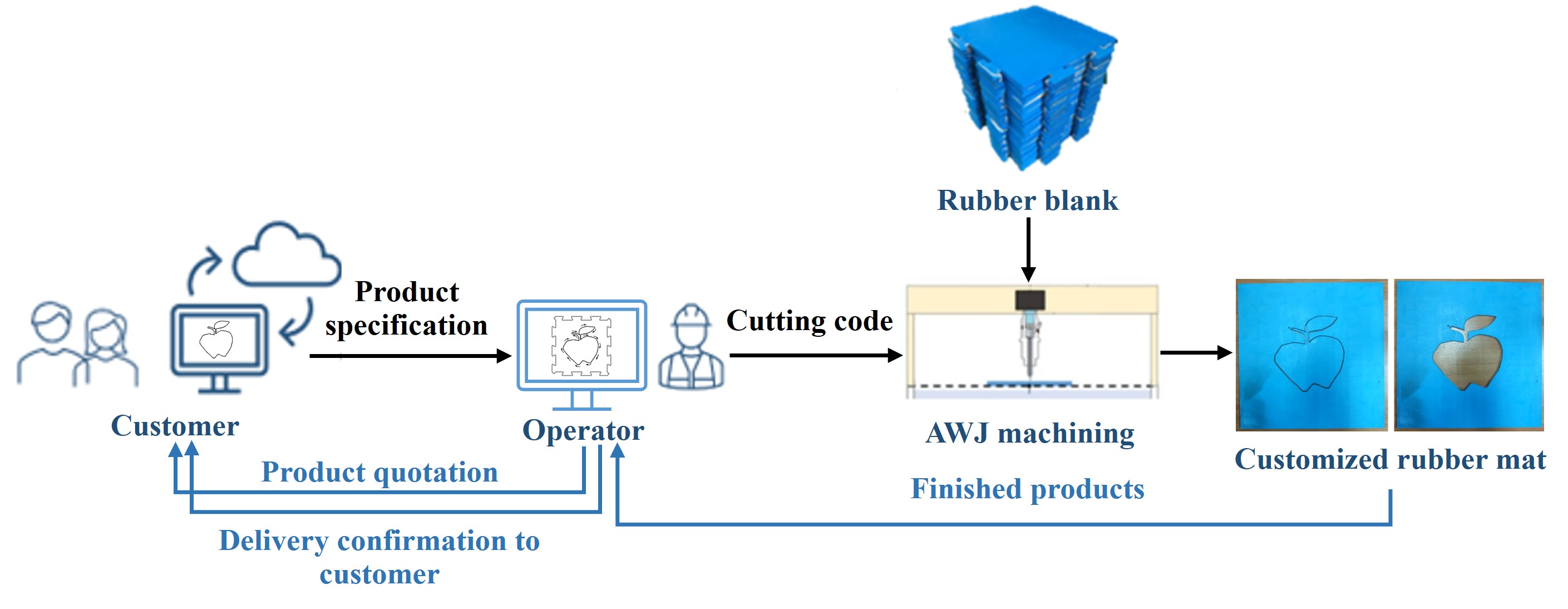

Molding is a widely used technique for large-scale manufacturing of rubber products, ensuring profitability for companies. Advances in rubber-based products have significantly improved consumer satisfaction by fostering direct engagement between manufacturers and customers. This study aims to develop a framework for transforming a blank rubber mat into a custom-designed jigsaw rubber mats using abrasive waterjet (AWJ) cutting. Customers can design their own rubber mats and submit digital images, which are then processed and cut by a waterjet machine to create jigsaw rubber mats. The optimal cutting path was developed based on the number of cutting points and the similarity index to ensure precise cutting operations. The production cost was subsequently analyzed, as the uniqueness of each design influences it. The evaluation of toolpath optimization and AWJ cutting application revealed that the number of cutting points could be reduced by more than 50% compared to the original fine cutting points while maintaining a similarity index above 99%. This reduction significantly shortened cutting time. The manufacturing of customized jigsaw rubber mats incurs only a minor additional cost, approximately 13% of the overall manufacturing cost of regular rubber mats. These findings suggest that this approach could provide manufacturers with a competitive advantage by enabling the production of customer-oriented products that are both responsive and economically feasible.

Article Details

อนุญาตภายใต้เงื่อนไข Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

เอกสารอ้างอิง

Bank of Thailand. Thailand Exports: Agriculture: Rubber. CEIC Data. https://www.ceicdata.com/en/thailand/exports-by-product-group/exports-agriculture-rubber (accessed 2022-01-26).

Isayev, A. I. Injection and Compression Molding Fundamentals; Marcel Dekker Inc.: New York and Basel, 1987. https://doi.org/10.1201/9780203750810

Murthy, B. S.; Eifler, T.; Howard, T. J.; McMahon, C. Mass Production Tools and Process Readiness for Uniform Parts—Injection Molding Application. J. Polym. Compos. 2017, 5(3), 311–320.

Fogliatto, F. S.; Silveira, G. J. C.; Borenstein, D. The mass customization decade: An updated review of the literature. Int. J. Prod. Econ. 2012, 138(1), 14–25. https://doi.org/10.1016/j.ijpe.2012.03.002

Wang, Y.; Ma, H. S.; Yang, J. H.; Wang, K. S. Industry 4.0: a way from mass customization to mass personalization production. Adv. Manuf. 2017, 5(4), 311–320. https://doi.org/10.1007/s40436-017-0204-7

Doner, R.; Abonyi, G. Upgrading Thailand’s Rubber Industry: Opportunities and Challenges. Thammasat Econ. J. 2013, 31(4), 44–66.

Mitsomwang, P.; Nagasawa, S.; Kuroiwa, H.; Fukushima, Y. Deformation Analysis of Silicone Rubber Sheet Subjected to Keen WC Blade Indentation. Int. J. Autom. Technol. 2024, 8(5), 761–772. https://doi.org/10.20965/ijat.2014.p0761

Kojima, M.; Nagasawa, S.; Igarashi, Y. Cutting Characteristics of Silicone Rubber Sheet with Respect to Indentation Velocity of Keen Wedge Blade. J. Jpn. Soc. Technol. Plast. 2020, 61(708), 1–6. https://doi.org/10.9773/sosei.61.1

Mispan, M. S.; Mustafa, A. H.; Sarkawi, H.; Jidin, A. Z. Low-cost and portable automatic sheet cutter. Int. J. Electr. Comput. Eng. 2020, 10(5), 5139–5146. https://doi.org/10.11591/ijece.v10i5.pp5139-5146

Mizzi, L.; Salvati, E.; Spaggiari, A.; Tan, J. C.; Korsunsky, A. M. Highly stretchable two-dimensional auxetic metamaterial sheets fabricated via direct-laser cutting. Int. J. Mech. Sci. 2020, 167, 105242. https://doi.org/10.1016/j.ijmecsci.2019.105242

Mizzi, L.; Salvati, E.; Spaggiari, A.; Tan, J. C.; Korsunsky, A. M. A decision guidance framework for non-traditional machining processes selection. Ain Shams Eng. J. 2018, 9(1), 203–214. https://doi.org/10.1016/j.asej.2015.10.013

Hu, Y.; Kang, Y.; Wang, X. C.; Li, X. H.; Long, X. P.; Zhai, G. Y.; Huang, M. Mechanism and Experimental Investigation of Ultra High-Pressure Water Jet on Rubber Cutting. J. Precis. Eng. Manuf. 2014, 15(9), 1973–1978. https://doi.org/10.1007/s12541-014-0553-0

Tangwarodomnukun, V.; Koomsap, P.; Chowdhary, A. A Preliminary Study of Applying Waterjet for Rapid Prototyping. Presented at The 11th Asia Pacific Industrial Engineering and Management Systems Conference, Melaka, Malaysia, 2010.

Natarajana, Y.; Murugesan, P. K.; Mohan, M.; Khan, S. A. L. A. Abrasive water jet machining process: a state of art of review. J. Manuf. Processes 2020, 49, 271–322. https://doi.org/10.1016/j.jmapro.2019.11.030

Chen, J. F.; Yuan, Y. M.; Gao, H.; Zhou, T. Y. Smoothing strategy for corner of small curvature radius by abrasive waterjet machining. Adv. Manuf. 2023, 11(2), 390–406. https://doi.org/10.1007/s40436-023-00443-3

Andersson, U.; Holmqvist, G. Strategies for Cost- and Time-effective Use of Abrasive Waterjet Cutting. Presented at WJTA American Waterjet Conference, Houston, Texas, 2005.

Radovanovic, M. Abrasive waterjet cutting cost. Nonconventional Technol. Rev. 2007, 1(1), 97–102.

Radovanović, M. Cost optimization of abrasive water jet cutting using GA. Tribol. J. BULTRIB 2013, 3(3), 70–75.

Ciupan, E.; Ciupan, C.; Lungu, F. The cost estimation of a water jet cutting process using artificial neural networks. Nonconventional Technol. Rev. 2018, 22(4), 26–30.

Radovanovic, M. Multi-Objective Optimization of Abrasive Water Jet Cutting Using MOGA. In 23rd International Conference on Material Forming (ESAFORM 2020); Elsevier: Amsterdam, 2020, 47, 781–787. https://doi.org/10.1016/j.promfg.2020.04.241

Kuagoolkijgarn, P.; Koomsap, P. Applying Image Processing for Rapid Customization of Multi-Color Nested Pattern Products. In New World Situation: New Directions in Concurrent Engineering. Advanced Concurrent Engineering; Springer: London, 2010; pp 401–414. https://doi.org/10.1007/978-0-85729-024-3_40.

Thai Industrial Standard Institute. Rubber Flooring: TIS 2377-2008; Thai Industrial Standard: Thailand, 2008.

Feng, H. Y.; Teng, Z. Iso-planar piecewise linear NC tool path generation from discrete measured data points. Comput.-Aided Des. 2005, 37(1), 55–64. https://doi.org/10.1016/j.cad.2004.04.001

MathWorks. Image Processing Toolbox User Guide; The MathWorks, Inc: 2023.

Wang, J. Abrasive Waterjet Machining of Engineering Materials; Trans Tech Publications Inc, 2003. https://doi.org/10.4028/www.scientific.net/MSFo.19

Kirdwan, P.; Thongkaew, K.; Daesa, C.; Chaiprapat, S. Influence of Abrasive Waterjet Cutting on Efficiency of Cutting Rubber Floor Mats. J. King Mongkut’s Univ. Technol. North Bangkok 2025, 35(1), 1–12. https://doi.org/10.14416/j.kmutnb.2024.09.004

Thongkaew, K.; Naemsai, T.; Mustafa, Z. Cost Estimation for Post Abrasive Waterjet Cutting on Customized Jigsaw Rubber Mats. J. Adv. Manuf. Technol. 2023, 1(1), 1–16.

Krachangphiphop, P.; Wannasin, J.; Meemongkol, N. Process-based cost modelling for gas induced semi-solid-processed below-knee prosthesis. Int. J. Prod. Res. 2018, 56(4), 1361–1368. https://doi.org/10.1080/00207543.2017.1364441

MathWorks. Optimization Toolbox User Guide; The MathWorks, Inc: 2023.