Designing and Developing Quality Control of Processes Using the Failure Mode and Effects Analysis Method and Machine Learning

Main Article Content

Abstract

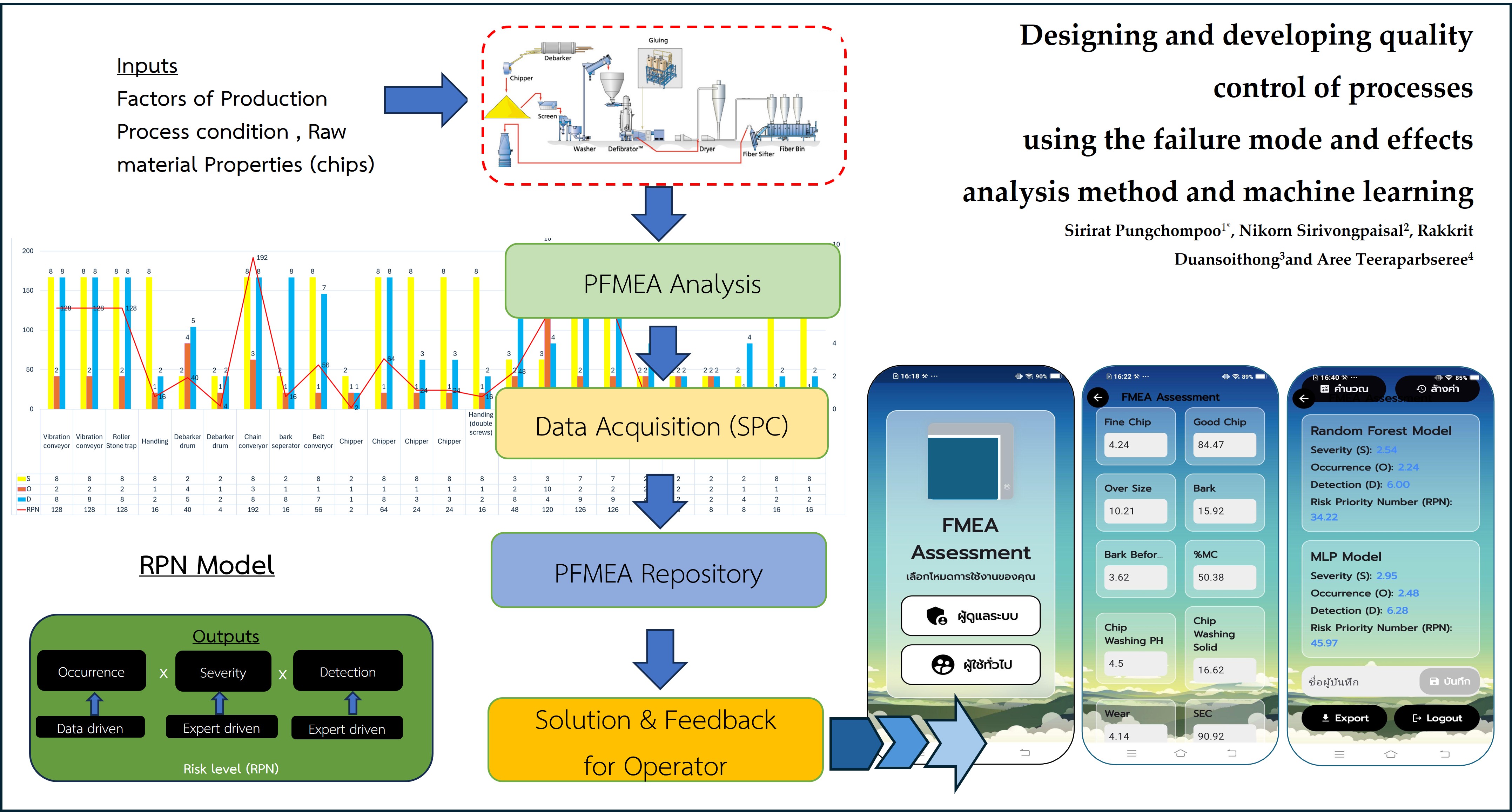

Medium-density fiberboard (MDF) production involves multiple intricate stages. Uneven thickness formation, large volumes of dynamic data from automated systems, and rapidly evolving technologies create substantial challenges for maintaining consistent quality control. Conventional approaches rely heavily on expert judgment and lack predictive capability, leaving a critical gap in timely and accurate risk assessment. This study addresses these challenges by integrating Failure Mode and Effects Analysis (FMEA) with machine learning techniques to evaluate and predict risks throughout the MDF production process. Real production data from an industrial facility were used to ensure practical relevance. Domain experts first assessed the Severity (S), Occurrence (O), and Detection (D) parameters using the PFMEA method. Predictive models—including K-Nearest Neighbors, Support Vector Machine, Neural Network, and an Ensemble Method—were then developed to estimate risk scores. The findings show that the Neural Network and Ensemble Method achieved the highest overall accuracy. This integrated approach reduces subjective bias, enhances predictive precision, and supports informed decision-making for quality control and risk mitigation in industrial MDF production.

Article Details

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

References

Jiang, S.; Liu, Z.; Chen, J. A Dynamic Failure Mode and Effect Analysis (FMEA) Method for CNC Machine Tool in Service. J. Phys.: Conf. Ser. 2023, 2483, 012047. https://doi.org/10.1088/1742-6596/2483/1/012047

Bangun, C. S.; Maulana, A.; Rasjidin, R.; Rahman, T. Application of SPC and FMEA Methods to Reduce the Level of Hollow Product Defects. J. Tek. Ind. 2022, 8(1), 12–16. https://doi.org/10.24014/jti.v8i1.16681

Nurdaningsih, N. W.; Yunitasari, E. W.; Ma’arif, S. Statistical Process Control (SPC) and Fuzzy-Failure Mode and Effect Analysis (F-FMEA) Approaches to Reduce Reject Products in Wine Bottle Rack Production Process at PT Alis Jaya Ciptatama. Opsi 2022, 15(2), 274–283. https://doi.org/10.31315/opsi.v15i2.7567

Appollis, L.-L. M.; van Dyk, W. A.; Matope, S. Using Failure Modes and Effects Analysis as a Problem-Solving Guideline When Implementing SPC in a South African Chemical Manufacturing Company. S. Afr. J. Ind. Eng. 2020, 31(1), 157–169. https://doi.org/10.7166/31-1-2294

Keskin, G. A.; Özkan, C. An Alternative Evaluation of FMEA: Fuzzy ART Algorithm. Qual. Reliab. Eng. Int. 2009, 25 (6), 647–661. https://doi.org/10.1002/qre.984

Balaraju, J.; Govinda Raj, M.; Murthy, C. S. Fuzzy-FMEA Risk Evaluation Approach for LHD Machine – A Case Study. J. Sustain. Min. 2019, 18(4), 257–268. https://doi.org/10.1016/j.jsm.2019.08.002

Spreafico, C.; Sutrisno, A. Artificial Intelligence Assisted Social Failure Mode and Effect Analysis (FMEA) for Sustainable Product Design. Sustainability 2023, 15(11), 8678. https://doi.org/10.3390/su15118678

Góes, A. L. B.; Kazmi, R.; Aqsa, A.; Nuthakki, S. A Hybrid AI-Based Risk Assessment Framework for Sustainable Construction: Integrating ANN, Fuzzy Logic, and IoT. Int. J. Adv. Comput. Sci. Appl. 2025, 16(3), 46–56.

Lu, Q.; Zeng, W.; Guo, Q.; Lü, S. Optimal Operation Scheduling of Household Energy Hub: A Multi-Objective Optimization Model Considering Integrated Demand Response. Energy Rep. 2022, 8, 15173–15188. https://doi.org/10.1016/j.egyr.2022.11.047

Doz, D.; Cotič, M.; Felda, D. Random Forest Regression in Predicting Students’ Achievements and Fuzzy Grades. Mathematics 2023, 11(19), 4129. https://doi.org/10.3390/math11194129

Muchlinski, D.; Siroky, D.; He, J.; Kocher, M. Comparing Random Forest with Logistic Regression for Predicting Class-Imbalanced Civil War Onset Data. Political Analysis 2016, 24(1), 87–103. https://doi.org/10.1093/pan/mpv024

Program, D. F.; Prijadi, R. FMEA-Based Logistic Regression Model for the Evaluation of Photovoltaic Power Plant Risk. Quant. Econ. Manag. Stud. 2024, 5, 644-657. https://doi.org/10.35877/454RI.qems2645